Since 2023, the Dutch VDL Enabling Technologies Group (VDL ETG) has had a branch in Park Innovaare in Villigen – right next to the Paul Scherrer Institute PSI. As part of the family-owned VDL Groep, VDL ETG is a global supplier to companies that build high-tech manufacturing equipment and use state-of-the-art production lines. Hans Priem is Business Development Manager at VDL ETG. Cees Maris has primary responsibility for VDL ETG at Park Innovaare.

What does your company manufacture?

Hans Priem: We are a so-called contract manufacturing partner. For example, our customers may sell machines for manufacturing semiconductors or products used in analytics, aerospace, medicine and many other fields. These machines are immensely complex; they may use a high vacuum, for example, and have very high accuracies and a huge throughput. Our customers outsource part of the development, production, assembly and testing of modules or entire systems to us. So we are active in the field of high-end and high-tech contract manufacturing.

What does advanced manufacturing mean to you?

Cees Maris: In our industry, we are always striving to push the boundaries of what is possible. To do this, we need to understand in detail the physics behind the products we develop. This allows us to offer our customers optimised solutions that result in firstclass performance of innovative products. I would call this approach advanced manufacturing, and we believe that it can be achieved through intensive collaboration with PSI and other partners in Park Innovaare, as well as by connecting research and industry.

Hans Priem: At the moment we have the right infrastructure and thus the capabilities to serve our customers’ needs. But the challenge is not just to have these technologies available now. Today, we are already thinking about what will be needed in five or ten years’ time. Based on input from our customers as well as our own assessments and initiative, we decided to strengthen our existing relationship and our already intensive cooperation with PSI and to establish a branch at Park Innovaare. We know the institute very well, having already worked with PSI on the construction of the SwissFEL and various other projects.

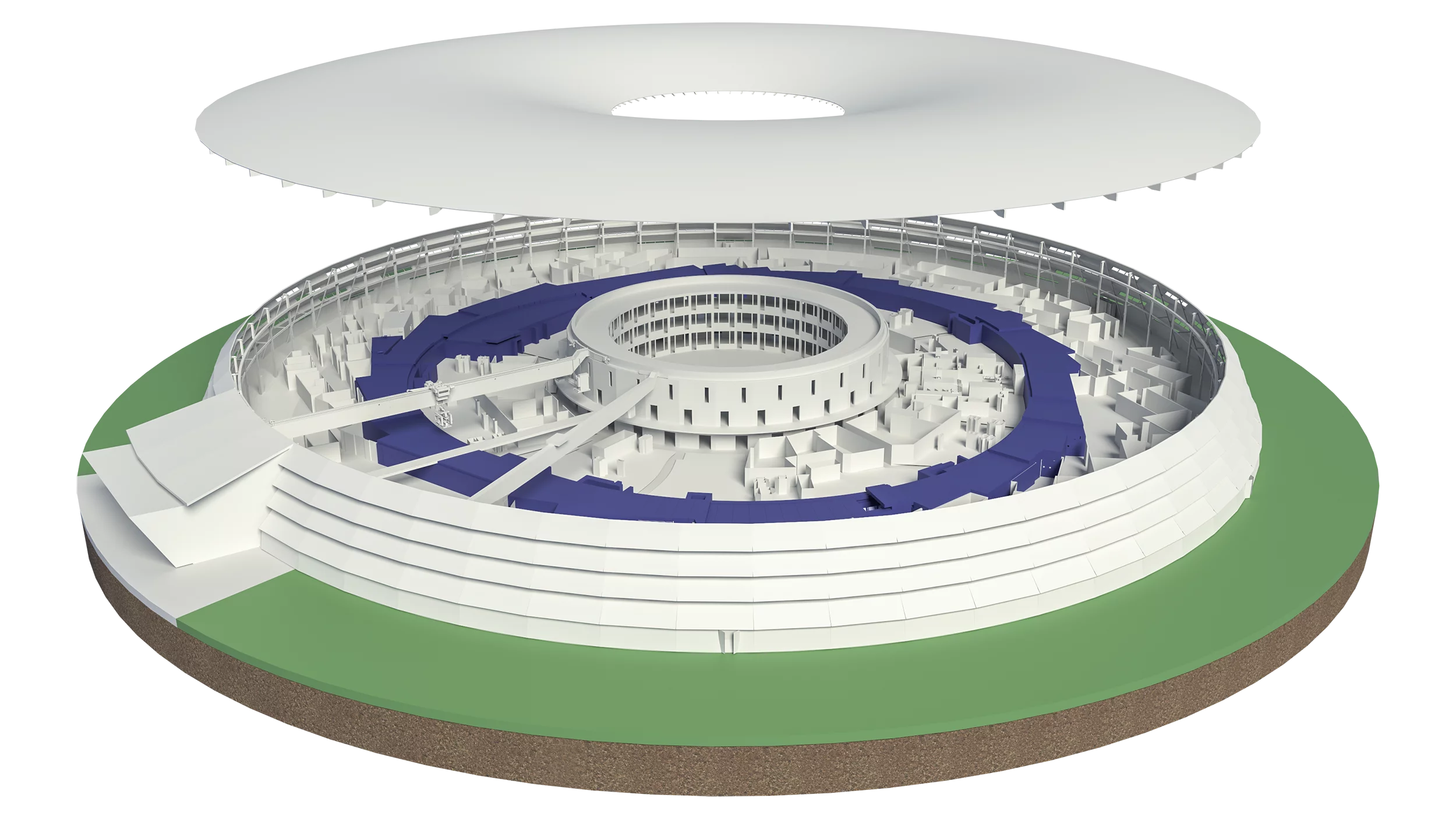

The X-ray free-electron laser SwissFEL is the latest large research facility at PSI. What was VDL ETG’s contribution to the construction of this more than 700-metre-long facility, which includes a linear accelerator?

Hans Priem: We manufactured more than 12,000 high-precision components that together form the central elements of the SwissFEL accelerator tube. These specially shaped copper discs have to meet very precise dimensional and positional tolerances of a few micrometres, and the geometry varies from disc to disc. The discs were manufactured by VDL ETG Switzerland in Trübbach in eastern Switzerland. It was something quite special for us to be able to produce such a large number with such high precision. If you are good at precision manufacturing – and I think we are – it’s very important to get involved in projects like this because of the advances in technology. This is an opportunity for us to develop our skills and then apply this precision manufacturing to our main business areas, for example as a supplier for the construction of special large high-resolution electron microscopes and for our customers in the semiconductor industry.

To what extent can accelerator technology be used in semiconductor production?

Cees Maris: One of the areas we work in is semiconductor metrology, the technology used to make measurements. We find that there is an ever-increasing need for the inspection of microchips and wafers, because the semiconductor industry requires so many steps to produce a chip and to finish a wafer – often there are 600 process steps for a wafer. Testing and measurement methods are needed for quality control. Accelerator-based X-ray light sources are becoming increasingly important for these inspections. With the Swiss Light Source SLS and the X-ray free-electron laser SwissFEL, PSI has a lot of expertise in the field of accelerator-based X-ray light sources. Realising such large research facilities also requires strong magnets and a good vacuum. These aspects also apply to many of our products. So the technology behind them is also of great interest to us.

Hans Priem: In addition, accelerator technology is used in medicine, for example in proton therapy, which PSI has pioneered. And it is important for the development of Flash therapy, a very targeted cancer treatment in which very high doses of radiation are administered in short pulses.

So the areas in which VDL ETG is active partly overlap with the research areas of PSI?

Hans Priem: Yes, researchers at PSI are actually studying the same challenges as we are, but from a different angle. The combination of these two perspectives leads to a number of important new insights on both sides. This is also why it is strategically important for us to be part of Park Innovaare and PSI. It is a longterm investment to ensure that we will still be successful in five years’ time. In the projects we carry out at sites in the Netherlands, we sometimes work on questions for which PSI may already have answers. We want to contribute to such projects through our team at Park Innovaare.

Could you give us an example?

Hans Priem: Yes, for example, we are part of the team that is building the prototypes for microchip inspection. Another area is magnet and low-temperature or cryogenic technology. If you build a prototype but don’t understand the details of the physical principles involved, you could run into problems later during production. That’s why it makes much more sense to locate such a prototype project at Park Innovaare. If we run into something that we don’t understand, we can simply walk across the street to PSI and talk to the right experts with the right skills, who can help us.

What specific prototype project are you currently working on with researchers at PSI?

Cees Maris: Together with the team from the Magnet Section at PSI, we are conducting experiments on so-called pulsating heat pipes (PHP) at very low temperatures. A PHP is a tube filled with a medium that exists in both the gaseous and liquid phase in the temperature range applied. Gas bubbles created in the PHP cause the liquid to move back and forth. The idea is that we can use the PHP to transport heat from a superconducting magnet to the cooling system very efficiently. Superconducting magnets are increasingly used in accelerators and magnetic resonance imaging. Superconductivity offers a number of advantages. You can make very strong magnets that use little energy. However, they have to be cooled to very low temperatures. Our joint team built a test bed in the PSI Magnets laboratory. We filled the PHP with neon and tested the thermal conductivity at temperatures of minus 245 degrees Celsius. The facilities at PSI for this type of experiment are very good, but above all it was the people from the Magnet Section, the Department of Accelerator Technology and the Vacuum Section who made this project possible in a very pleasant collaboration. The initial results of these experiments are promising. We see potential applications for these technologies in the semiconductor industry and in space exploration. For the latter, an interesting aspect is that the system works without gravity.

Would you say that your collaboration with PSI and here at Park Innovaare is something special?

Hans Priem: I cannot stress enough how important our friendship with PSI and the Park Innovaare team is to us. Rationally speaking, it’s strategic in nature, but it’s also a lot of fun. And we are very proud to be part of this enormously productive and innovative network.

VDL Groep is an industrial group and family business based in Eindhoven, the Netherlands. VDL Enabling Technologies Group (VDL ETG) is part of VDL Groep and employs around 6,000 people worldwide. One of VDL ETG’s locations is in Trübbach in eastern Switzerland. VDL ETG Switzerland has around 200 employees and specialises in the system integration of high-precision components, mechatronic systems and complete modules in various sectors of the high-tech industry. Dutch-born Hans Priem has been a manager at VDL ETG since 2010. Cees Maris, also from the Netherlands, is an engineer who has been working at VDL ETG since 2018 and has been building up the VDL ETG office in Park Innovaare since 2023.