The PSI Laboratory for Electrochemistry studies almost all aspects of electrochemical energy conversion to advance its scientific and technological understanding for sustainable energy systems.

Vision

We aim to be a global leader in advancing electrochemical energy conversion, driving innovation for a sustainable, clean energy future through excellence in research, collaboration, and education.

Mission

We advance electrochemical science and technology by driving innovation in sustainable energy conversion systems and developing advanced materials. By bridging the gap between fundamental research and practical, real-world applications, we ensure that our discoveries lead to tangible impacts. We foster strong, collaborative partnerships across disciplines and industries, leveraging collective expertise to accelerate progress. Additionally, we are committed to empowering the next generation of leaders through comprehensive education and training programs. Ultimately, our efforts are directed towards creating effective, scalable solutions that address the pressing global challenges of energy sustainability.

Strategy

Our approach is centered on research excellence, utilizing state-of-the-art facilities and groundbreaking methods to drive fundamental discoveries and advancements in electrochemical energy technologies. We emphasize collaborative synergy, fostering strong partnerships across academia, industry, and laboratory groups to facilitate knowledge transfer and accelerate innovation. Our focus is on developing next-generation materials and solutions that meet critical challenges in sustainable energy conversion, ensuring enhanced durability and performance. We are equally committed to education and impact, equipping future leaders through comprehensive training programs, active community engagement, and a strong presence in the scientific community. Together, these pillars reflect our unwavering commitment to sustainability, innovation, and leadership in electrochemistry.

Career and Education within the Laboratory for Electrochemistry

Lab News & Scientific Highlights

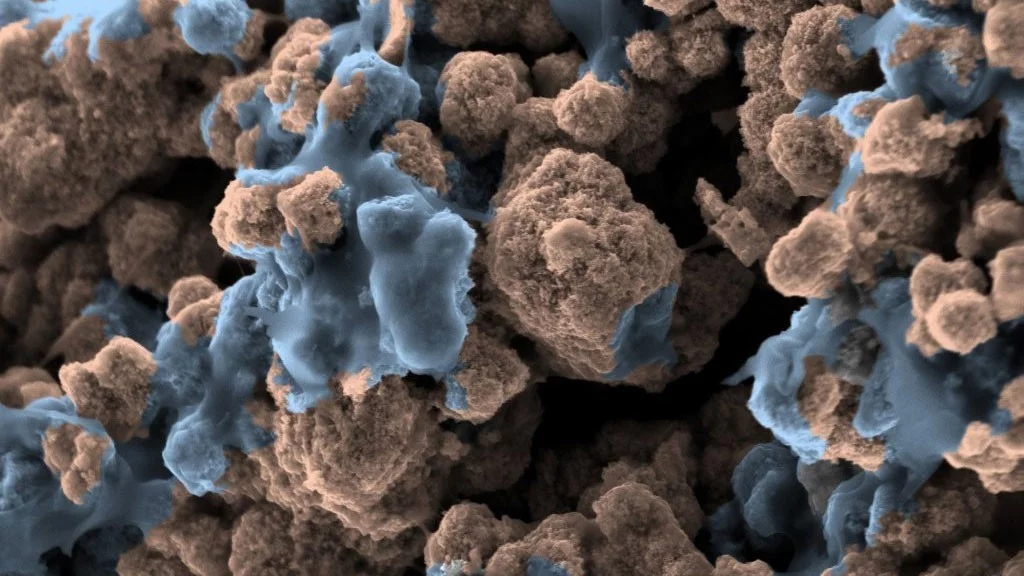

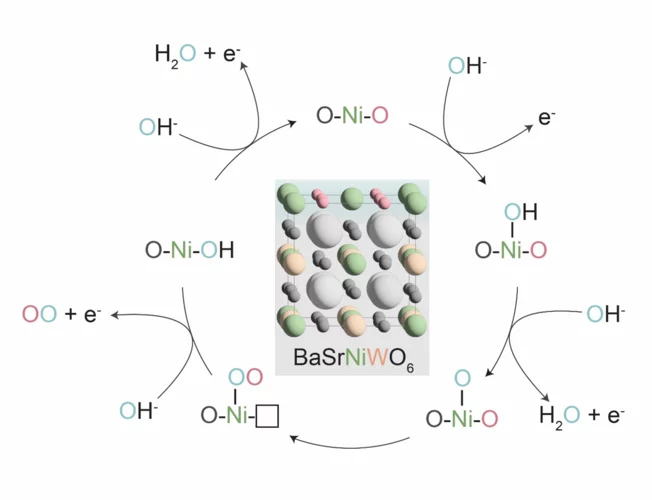

Confining surface oxygen redox in double perovskites for enhanced oxygen evolution reaction activity

Nickel-based double perovskites AA’BB’O6 are an underexplored class of oxygen evolution reaction (OER) catalysts. In particular, BaSrNiWO6 exhibits high oxygen evolution activity, attributed to the evolution of a highly OER active surface phase. The redox transformation of Ni2+(3d8) to Ni3+(3d7) combined with partial W dissolution into the electrolyte drives an in-situ reconstruction of the surface to an amorphized, NiO-like layer, promoting oxygen redox in the OER mechanism.

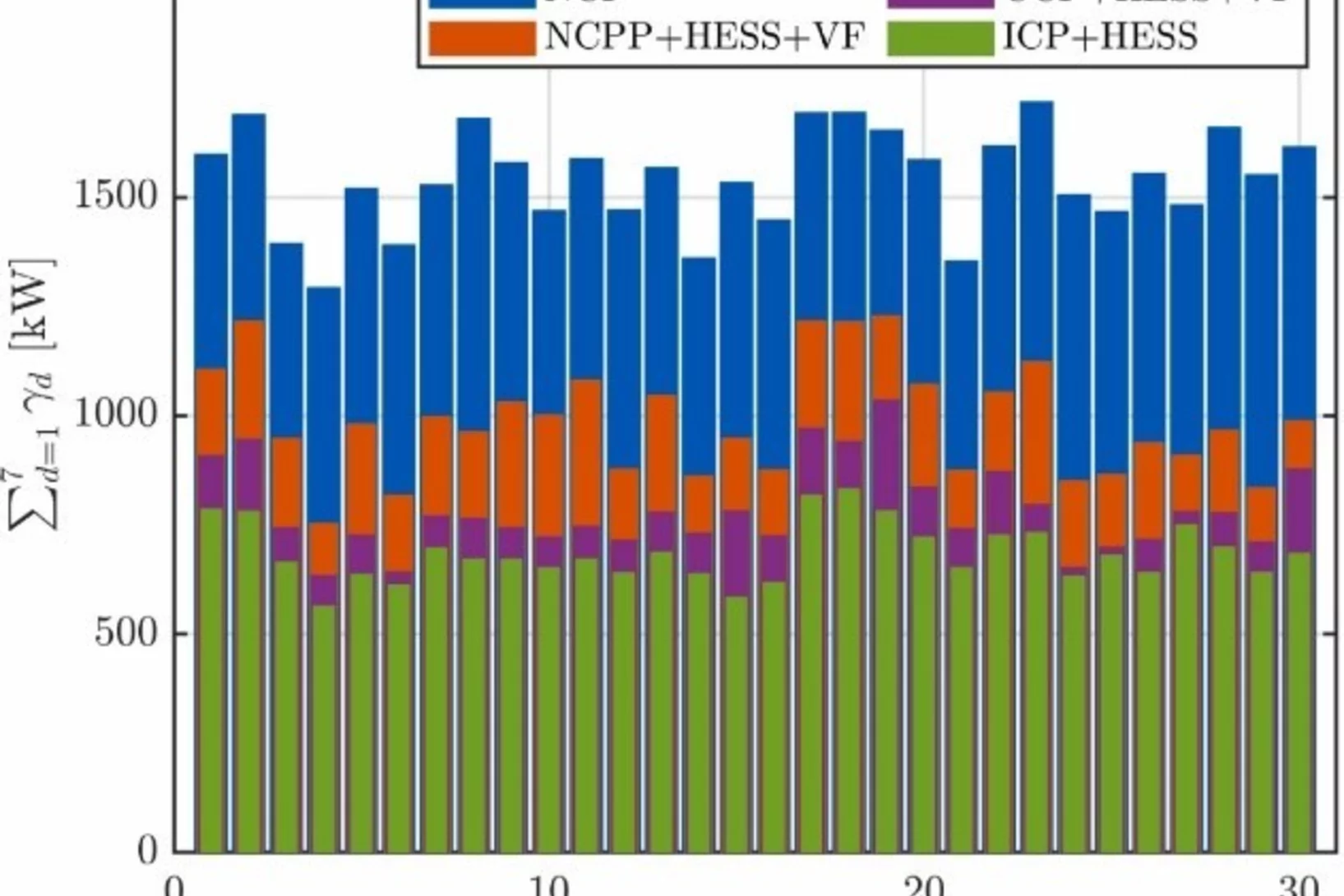

Decentralized hydrogen-based stationary energy storage systems complemented by smart control can provide increased operational flexibility in the energy system

While the electrification of the energy system implies a reduction of greenhouse gas emissions greatly beneficial to society, it can also pose technical challenges. The most notable among these are that the capacity of the local electric grid may be exceeded, along with the occurrence of imbalances between decentralized renewable energy production and final consumption. Hydrogen-based energy storage systems (HESS) are regarded as promising solutions to address these challenges. However, the feasibility has not been demonstrated and the involved processes are not well characterized on a technical relevant power level, so far.

Understanding the Interplay between Artificial SEI and Electrolyte Additives in Enhancing Silicon Electrode Performance for Li-Ion Batteries

Maintaining a stable solid electrolyte interphase (SEI) is crucial for Li-ion battery safety, especially with high-capacity anode containing silicon. Therefore, our study explored long-term cycling of Si electrodes with artificial alucone-based SEI, deposited by molecular layer deposition (MLD) in combination with a fluoroethylene carbonate (FEC) electrolyte additive. MLD of flexible Li-ion permeable artificial SEI coatings onto electrode resulted in improved capacity, enhanced Si electrode cycle life and capacity retention.

Publications

-

Li X, Zhang Q, Wang R, Huang J, Han J, Yao T, et al.

Driving fast-charging for sodium ion batteries in wide temperature range by metallic 1T phase ReSe2

Advanced Functional Materials. 2026. https://doi.org/10.1002/adfm.202528353

DORA PSI -

Liu H, Huang J, Ma S, Xiong R, Zhao J, Fu Q, et al.

Valence-Engineering of CeO2 Redox Modulator Boosts the Oxygen Electrocatalysis Performance in Fe/Co Dual-Atom Catalyst

Advanced Science. 2026. https://doi.org/10.1002/advs.202516405

DORA PSI -

Melčák M, Durďáková T‐M, Číhal P, Šercl J, Lee J, Boillat P, et al.

Interfacial behavior of methane in methane/p‐xylene/water systems: first principles inspected using neutron imaging and molecular dynamics simulations

Advanced Materials Interfaces. 2026: e00786 (10 pp.). https://doi.org/10.1002/admi.202500786

DORA PSI -

Wang R, Liao X, Huang J, Zhang X, Li X, Wang X, et al.

Reconstructing a stable surface on pyrite-type iridium telluride to promote the oxygen evolution reaction in acid

Chem Catalysis. 2026: 101580 (13 pp.). https://doi.org/10.1016/j.checat.2025.101580

DORA PSI -

Winter E, Carreon Ruiz ER, Kondracki Ł, Srout M, Lee J, Boillat P, et al.

Towards understanding electrolyte-dependant dynamics and kinetics of lithium deposition and stripping by operando neutron imaging

Energy Storage Materials. 2026; 84: 104817 (10 pp.). https://doi.org/10.1016/j.ensm.2025.104817

DORA PSI