Don't ever let a violin go without varnish, researchers advise, on the basis of a new study. At the Paul Scherrer Institute PSI, they used neutron imaging to investigate what effects different coatings have on the wood of the instrument. Varnishing does in fact reliably protect against humidity, but it also influences the sound characteristics of the wood. So don't overdo it: "As much varnish as necessary, as little as possible", the researchers conclude. The results of their study have now been published in the journal Scientific Reports.

A violin maker varnishes the outside of a violin to make the wood more resistant to wear, dirt and ambient air. Such a varnishing consists of various pretreatments and the actual varnish, which are applied one after another. The top coating of varnish usually consists of natural resins dissolved in oil or alcohol.

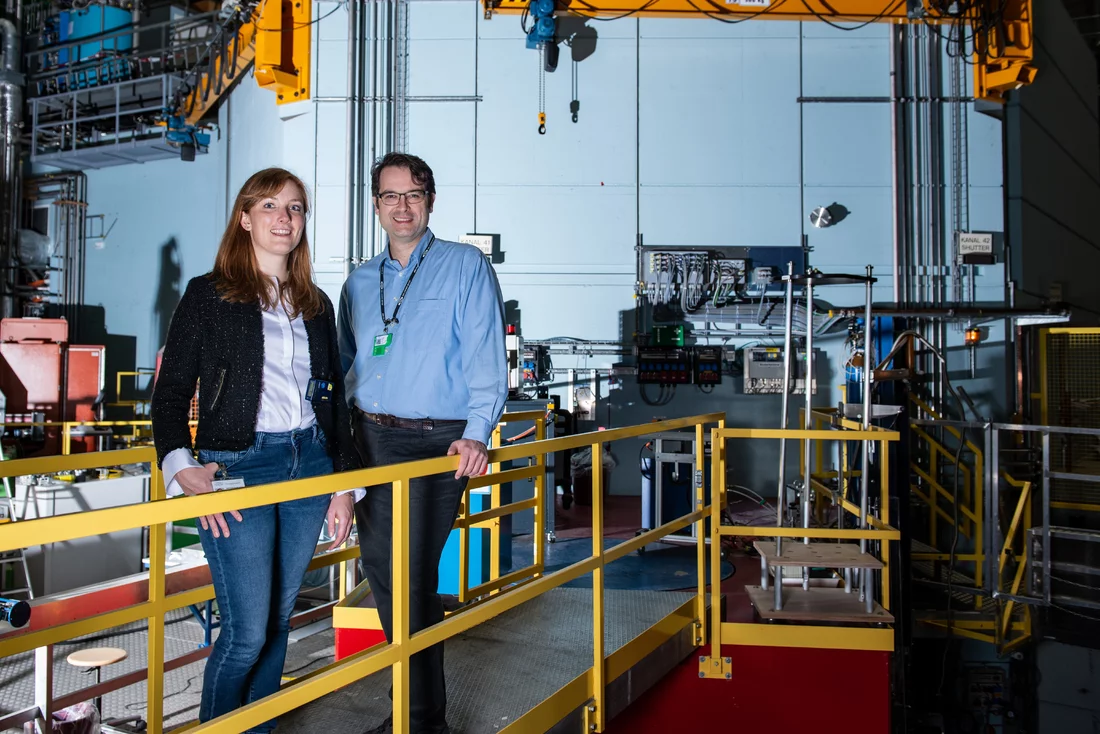

Researchers from the Paul Scherrer Institute PSI, ETH Zurich and the Swiss Federal Laboratories for Materials Science and Technology (Empa) have now investigated how different violin varnishing systems affect the absorption of moisture by the wood. They used the neutron source SINQ at PSI to capture images of what's happening in varnished as well as unvarnished wood samples. Sarah Lämmlein, an Empa researcher and first author of the study, sums up the findings: "Only a complete coating with pretreatment agents and varnish is really effective." The wood then absorbs only half as much water from the air as an untreated sample.

Absorbing and releasing moisture can seriously damage a violin: Swelling and contraction of the wood can lead to deformation or cracks. Moisture in the wood also changes the sound characteristics of the instrument.

Water made visible

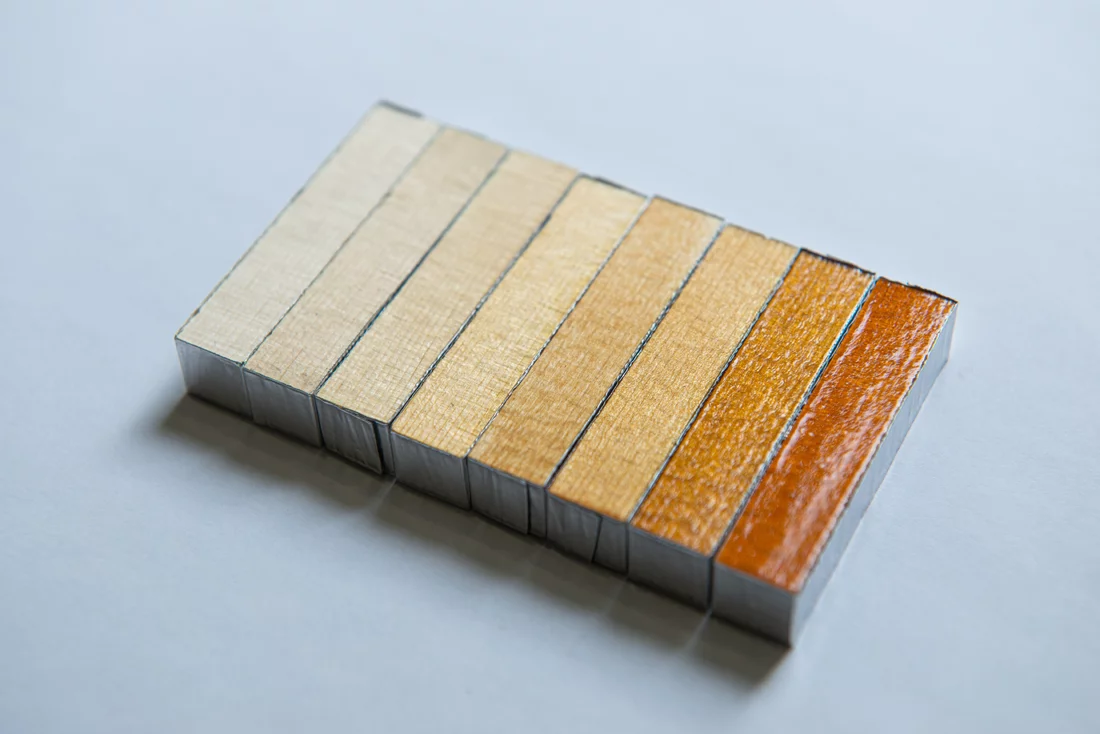

For their study, the researchers treated five-centimetre long pieces of violin wood with seven combinations of different pretreatment agents and top coats of varnish. Most violin varnishes are secret recipes – so Sarah Lämmlein sought advice from Ulrike Dederer, a master violin maker based in Zurich. Pretreatment agents penetrate the wood, while varnishes containing oil or alcohol lie on the surface of the wood to a thickness of up to 70 micrometres, around the width of a human hair.

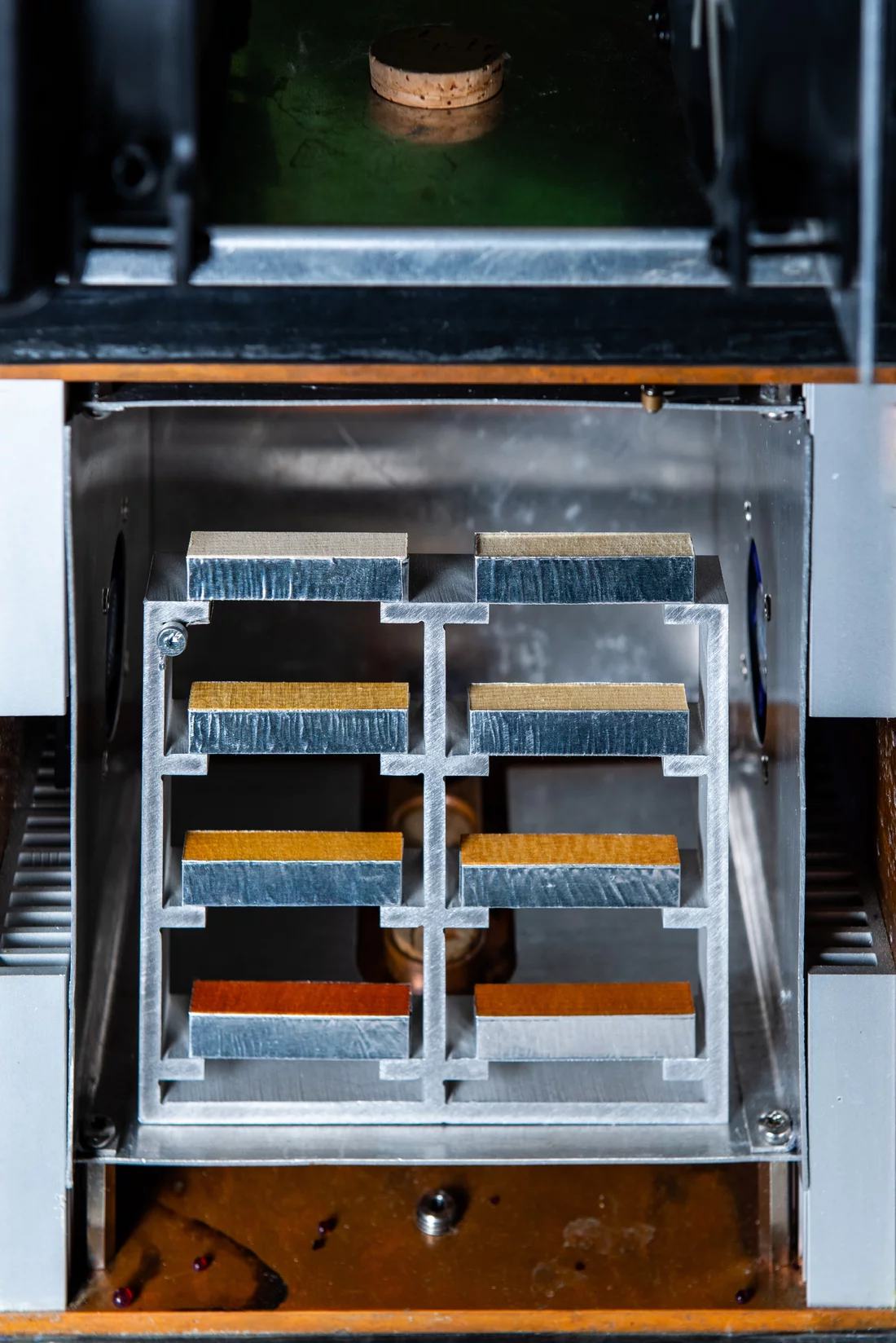

After drying, the researchers exposed the wood samples to humidity alternating between 95 and 35 percent in a climate chamber at SINQ. While the samples in the chamber were absorbing water and then releasing it again, the researchers probed them with neutrons. These uncharged elementary particles are deflected in flight from their straight path by hydrogen atoms, such as those occurring in water.

"Because the neutrons are so sensitive to hydrogen, we were able to see on the scale of one-tenth of a millimetre where the wood absorbs or releases water, how rapidly, and how much", explains David Mannes from PSI. The special thing about imaging with neutrons is that it functions non-destructively; this makes it possible to examine entire objects without damaging them. So dynamic processes taking place in a sample can be observed and quantified. This method is only carried out at a few other research institutes worldwide; in Switzerland, PSI is the only place it can be done.

Wood samples that were given only pretreatment agents but not a top coat of varnish were used to simulate a heavily worn violin, where the upper layers of varnish have already been rubbed off. Over time, this happens in places that are particularly stressed, such as the back of the violin where it is pressed against the player's shoulder. The corresponding samples quickly absorbed large amounts of water, since they were more or less directly exposed to the air. "So it can be worthwhile to touch up these places where the varnish has worn off", says David Mannes. It is especially damaging if the wood takes in different amounts of moisture in different places, since this can lead to tension in the wood that strongly promotes the formation or growth of cracks.

Every time a violin is transported, for example to and from a concert hall, the instrument is exposed to changing humidity. And it's not only from the air that moisture gets into the wood of the violin. The varnish also protects the instrument against the violin player's perspiration. Oil-based and alcohol-based varnishes offer comparably good protection against moisture.

Dampened vibration

You shouldn't overdo it, however, when it comes to varnishing. The researchers came to this conclusion after a vibrational modal analysis. The measurements show that more and thicker layers of varnish change the vibrational behaviour of the wood samples. "Every material vibrates differently, and varnish has a particularly strong dampening effect on the vibration", Sarah Lämmlein explains. The natural eigenfrequencies of slabs of wood shift altogether and are strongly dampened. Thus a varnished violin sounds different from an unvarnished one.

"You have to find a happy medium and keep the varnishing to a minimum", says Lämmlein. Traditionally, only the exterior of the violin is coated with multiple layers, but not the interior surfaces of the sound box. The researchers' analyses confirm that this approach is still the method of choice. After all, the inner surface has less direct exposure to the air and especially to the violin player's sweat.

The fact that varnishing can alter the sound of a violin also means that the luthier should take these changes into account when building it, so that the instrument ultimately sounds the way it was meant to.

The researchers' findings have been published in the journal Scientific Reports.

Text: Paul Scherrer Institute/Brigitte Osterath

Contact

Dr. David Mannes

Laboratory for Neutron Scattering and Imaging

Paul Scherrer Institute, Forschungsstrasse 111, 5232 Villigen PSI, Switzerland

Telephone: +41 56 310 46 10, e-mail: david.mannes@psi.ch [German, English]

Sarah Louise Lämmlein

Laboratory for Cellulose & Wood Materials

Empa, Überlandstrasse 129, 8600 Dübendorf, Switzerland

Telephone: +41 58 765 44 35, e-mail: sarah.laemmlein@empa.ch [German, English]

Original publication

The influence of multi-layered varnishes on moisture protection and vibrational properties of violin wood

S. L. Lämmlein, D. Mannes, B. van Damme, F. W. M. R. Schwarze, I. Burgert

Scientific Reports, 09.12.2019 (online)

DOI: 10.1038/s41598-019-54991-5