The invisible becomes visible within lithium-sulphur batteries

Materials researchers of the Paul Scherrer Institute PSI in Switzerland have, in collaboration with the Université Grenoble Alpes (France), developed a method that could enable a breakthrough for the lithium-sulphur battery. In theory, lithium-sulphur batteries can deliver considerably more energy than today's conventional lithium-ion batteries, but current prototypes show a distinct loss of capacity after just a few charging cycles. As a result, they are not yet fit for widespread use, for instance in electric vehicles. With their new method, the researchers were able to gain crucial insights into how the rapid capacity loss occurs. And they showed: if quartz powder is added to the liquid component of the battery, this loss can be slowed down. The researchers report their results in the latest edition of the scientific journal Nature Energy.

The lithium-sulphur battery is considered a promising candidate for future energy storage devices: The materials required are inexpensive, environmentally friendly, and readily available. Above all, this type of battery can theoretically deliver around three times as much energy as today's widely used lithium-ion battery. In practice, however, there are still several hurdles: For example, the lithium-sulphur battery rapidly loses capacity with repeated charging. Present-day prototypes manage far fewer charging cycles than conventional lithium-ion batteries – and besides that, they deliver only a fraction of the theoretically possible energy.

Electrochemistry researchers at PSI gained new insights into the processes responsible for the capacity loss by developing a special examination method using X-rays to track the chemical reactions that take place within the battery. They made directly visible, for the first time, the way lithium-sulphur compounds change and how this leads to the loss of capacity. And they observed for the first time how ordinary quartz powder – the principal constituent of sand and the main ingredient of glass – improves the lithium-sulphur battery: added to the liquid component of the battery, it increases the available energy and curbs the capacity loss that sets in over time. Other researchers had previously already determined that quartz powder interacts with the materials in lithium-sulphur batteries. Now the PSI researchers have quantified the gains that quartz powder can deliver: With this additive, a lithium-sulphur battery’s performance is improved by 25 to 30 percent

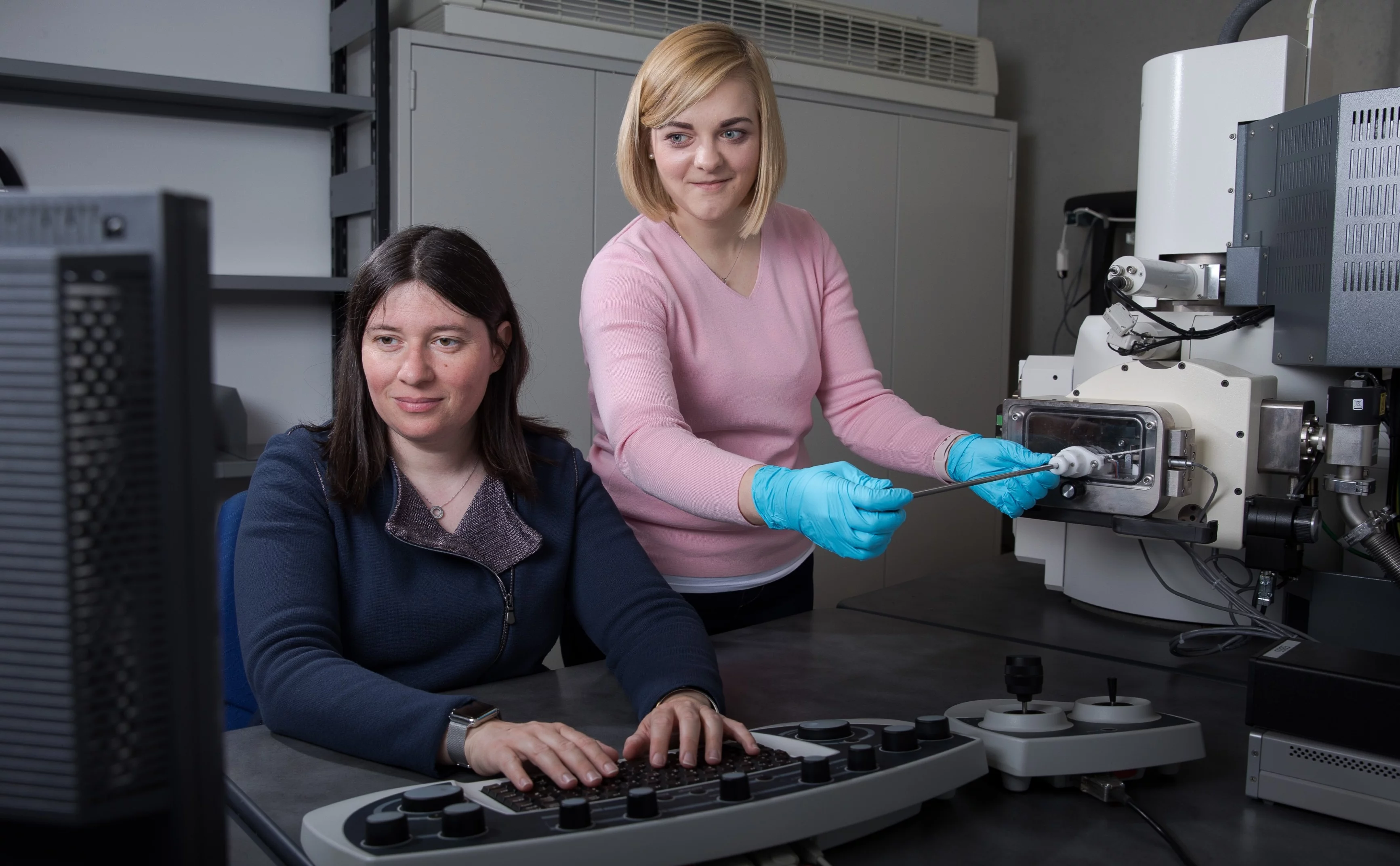

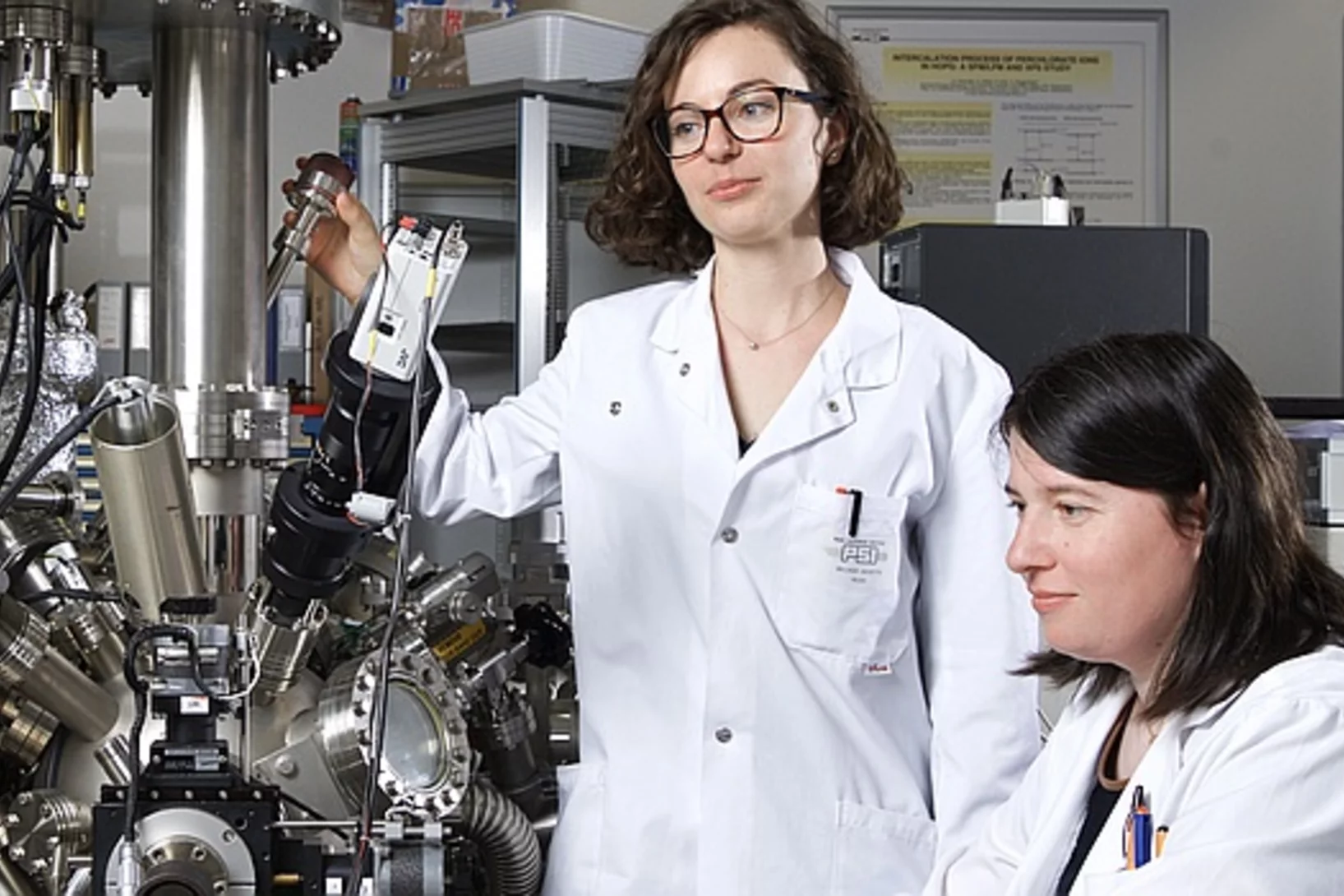

, says PSI researcher Claire Villevieille, co-author of the study. We simply added the quartz powder to the electrolyte – that is, the liquid component of the battery – like adding washing powder to the laundry

, Villevieille says.

Quartz powder against the dirt

The researchers have good reason to compare their additive to laundry detergent: the quartz powder does in fact bind a kind of dirt

in the battery. So-called polysulphides form during the operation of a lithium-sulphur battery. These are a normal constituent of an operating lithium–sulphur battery. A portion of them, though, will be lost to the battery's liquid component and then travel back and forth between its two electrodes with every charging and discharging cycle – the researchers call this a shuttle effect

. As a consequence, these rogue polysulphides react with the lithium electrode of the battery, thereby reducing the amount of available sulphur – the active material in the battery – and diminishing the battery's capacity.

This process can be counteracted through the addition of quartz powder. We found that quartz binds the polysulphides the way soap binds dirt

, Claire Villevieille reports. This increases and preserves the charging capacity, because the interior of the battery stays clean and functional for a longer time. The reversibility of the discharging process improves. We call this the Coulombic efficiency

, Villevieille says. It increases from around 80 percent to 90 percent.

By comparison, the Coulombic efficiency of a conventional lithium-ion battery is more than 99.9 percent. Evidently, there is still a long way to go to reach this figure; but it really is a big step already.

X-ray snapshots of a battery

The positive effect of the quartz was revealed when the PSI researchers, in cooperation with a colleague at the Université Grenoble Alpes, examined the chemical processes within the battery using a method known as operando X-ray diffraction. Ordinarily, liquids cannot be observed using this technique, and therefore the processes in the electrolyte remain hidden. X-ray diffraction works only on ordered, crystalline structures; the polysulphides in the electrolyte, however, normally move around in a disordered fashion

, explains Villevieilles's colleague Joanna Conder, first author of the study. To make the polysulphides visible, the researchers added glass fibres to the electrolyte. The polysulphides settled on the surface of the fibres in an orderly manner. Aligned in this way, the polysulphides diffract the X-rays and thus become visible. This enabled us for the first time to track the accumulation and transformation of the polysulphides inside the battery during charge and discharge

, Conder says.

Unexpectedly, the researchers found that the glass fibres reduced the unwanted accumulation of sulphides. Since glass consists mainly of quartz, the idea to begin using quartz powder as a kind of cleaning agent in the batteries was evident.

Inexpensive and straightforward

The two PSI researchers acknowledge that there are, in principle, other approaches by which polysulphides could be prevented from dissolving and contribute to limiting the battery function: But these are either very complicated or very expensive or both, especially when the method needs to be implemented on an industrial scale. Quartz, in contrast, is just about the cheapest material there is.

Introducing such a substance into the electrolyte is downright simple. That's the great advantage of our method

, says Joanna Conder.

Polysulphides and the polysulphide shuttle in the lithium-sulphur battery

When a lithium-sulphur battery is used, lithium ions migrate from the anode (negative terminal) to the cathode (positive terminal). When the lithium ions react with sulphur in the cathode, several electrolyte-soluble lithium-sulphur molecules, so-called lithium polysulphides, are formed that finally transform insoluble lithium sulphide. During the subsequent recharging of the battery, the products of discharge are transformed back to elemental sulphur. This is how the regular discharging and recharging process works, without presenting any problems for the battery's operation.

One unwanted effect in the lithium-sulphur battery is, however, that a portion of the polysulphides will cross over into the electrolyte – that is, into the liquid component between the two electrodes. Here these polysulphides travel back and forth between cathode and anode with every charging and discharging cycle; this is the so-called shuttle effect. In turn, a portion of the sulphides will accumulate on the metallic lithium anode of the battery.

The more often the battery is charged and discharged, the more sulphides accumulate on the anode. They thereby impair the charging and discharging of the battery. After several charging cycles, this can distinctly weaken the battery performance.

Contact

Dr. Claire Villevieille

Head of Battery Materials Group, Electrochemistry Laboratory,

Paul Scherrer Institute PSI

+41 56 310 24 10

claire.villevieille@psi.ch

[English, French]

Original Publication

-

Conder J, Bouchet R, Trabesinger S, Marino C, Gubler L, Villevieille C

Direct observation of lithium polysulfides in lithium-sulfur batteries using operando X-ray diffraction

Nature Energy. 2017; 2: 17069 (7 pp.). https://doi.org/10.1038/nenergy.2017.69

DORA PSI

Additional information

About PSI

The Paul Scherrer Institute PSI develops, builds and operates large, complex research facilities and makes them available to the national and international research community. The institute's own key research priorities are in the fields of future technologies, energy and climate, health innovation and fundamentals of nature. PSI is committed to the training of future generations. Therefore about one quarter of our staff are post-docs, post-graduates or apprentices. Altogether PSI employs 2300 people, thus being the largest research institute in Switzerland. The annual budget amounts to approximately CHF 450 million. PSI is part of the ETH Domain, with the other members being the two Swiss Federal Institutes of Technology, ETH Zurich and EPFL Lausanne, as well as Eawag (Swiss Federal Institute of Aquatic Science and Technology), Empa (Swiss Federal Laboratories for Materials Science and Technology) and WSL (Swiss Federal Institute for Forest, Snow and Landscape Research). (Last updated in June 2025)