Thanks to experiments at the Swiss Light Source SLS, a Swiss research team have resolved a long-standing debate surrounding laser additive manufacturing processes with a pioneering approach to defect detection.

The progression of laser additive manufacturing — which involves 3D printing of metallic objects using powders and lasers — has often been hindered by unexpected defects. Traditional monitoring methods, such as thermal imaging and machine learning algorithms, have shown significant limitations. They often either overlook defects or misinterpret them, making precision manufacturing elusive and barring the technique from essential industries like aeronautics and automotive manufacturing. But what if it were possible to detect defects in real time based on the differences in the sound the printer makes during a flawless print and one with irregularities? Up until now, the prospect of detecting these defects this way was deemed unreliable. However, a research team from EPFL, Paul Scherrer Institute PSI and the Swiss Federal Laboratories for Materials Science and Technology (Empa) have successfully challenged this assumption.

Roland Logé, head of the Laboratory of Thermomechanical Metallurgy at EPFL who led the study, stated, "There's been an ongoing debate regarding the viability and effectiveness of acoustic monitoring for laser-based additive manufacturing. Our research not only confirms its relevance but also underscores its advantage over traditional methods."

This research is of paramount importance to the industrial sector as it introduces a groundbreaking, yet cost-effective solution to monitor and improve the quality of products made through Laser Powder Bed Fusion (LPBF). Lead researcher, Milad Hamidi Nasab, remarked, "The synergy of synchrotron X-ray imaging with acoustic recording provides real-time insight into the LPBF process, facilitating the detection of defects that could jeopardize product integrity." In an era where industries continuously strive for efficiency, precision, and waste reduction, these innovations not only result in significant cost savings but also boost the dependability and security of manufactured products.

How Does LPBF Manufacturing Work?

LPBF is a cutting-edge method that's reshaping metal manufacturing. Essentially, it uses a high-intensity laser to meticulously melt minuscule metal powders, creating layer upon layer to produce detailed 3D metallic constructs. Think of LPBF as the metallic version of a conventional 3D printer, but with an added degree of sophistication. Rather than melted plastic, it employs a fine layer of microscopic metal powder, which can vary in size from the thickness of a human hair to a fine grain of salt (15–100 μm). The laser moves across this layer, melting specific patterns based on a digital blueprint. This technique enables the crafting of bespoke, complex parts like lattice structures or distinct geometries, with minimal excess. Nevertheless, this promising method isn't devoid of challenges.

When the laser interacts with the metal powder, creating what is known as a melt pool, it fluctuates between liquid, vapor, and solid phases. Occasionally, due to variables such as the laser's angle or the presence of specific geometrical attributes of the powder or of the part, the process might falter. These instances, termed "inter-regime instabilities", can sometimes prompt shifts between two melting methods, known as "conduction" and "keyhole" regimes. During unstable keyhole regimes, when the molten powder pool delves deeper than intended, it can create pockets of porosity, culminating in structural flaws in the end product. To facilitate the measurement of the width and depth of the melt pool in X-ray images, the Image Analysis Hub of the Center for Imaging developed an approach that makes it easier to visualize small changes associated with the liquid metal and a tool for annotating the melt pool geometry.

Detecting These Defects Using Sound

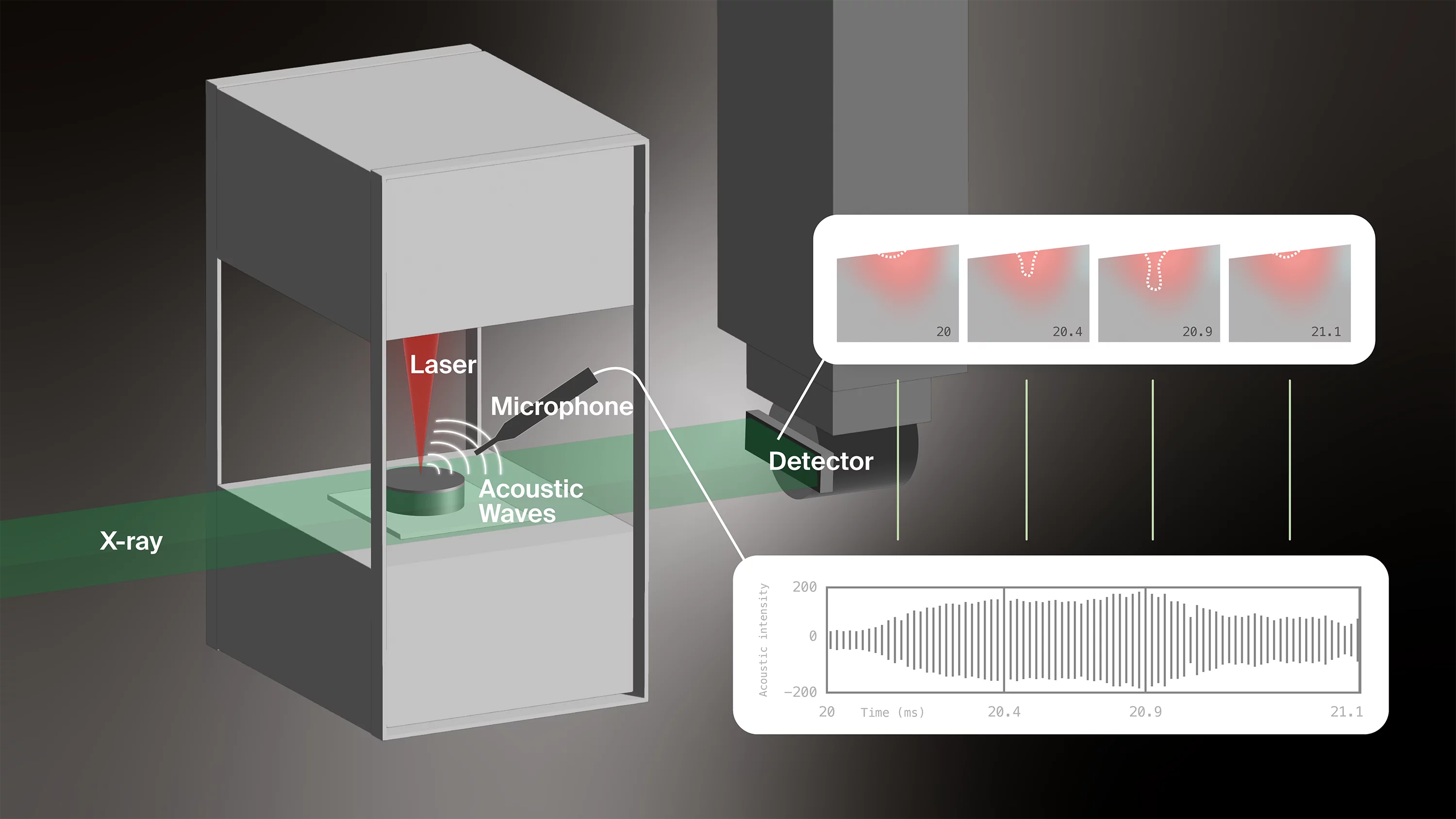

The research team formulated an experimental design that melded operando X-ray imaging experiments with acoustic emission measurements. The experiments were conducted at the TOMCAT beamline of the Swiss Light Source at PSI, with the miniaturized LPBF printer developed in the team of Steven Van Petegem.

During the fabrication of tiny metallic structures, the system concurrently captures X-ray radiographs at a very high speed. Van Petegem explains, "This capability enables us to observe the metal's behavior as it interacts with the laser”. The amalgamation with an ultra-sensitive microphone, positioned inside the printing chamber, pinpointed distinct shifts in the acoustic signal during regime transitions, thereby directly identifying defects during manufacturing.

A pivotal moment in the research was the introduction of an adaptive filtering technique by signal processing expert Giulio Masinelli from Empa. "This filtering approach," Masinelli emphasized, "allows us to discern, with unparalleled clarity, the relationship between defects and the accompanying acoustic signature." Unlike typical machine learning algorithms, which excel at extracting patterns from statistical data, but are often tailored to specific scenarios, this approach provides broader insights on the physics of melting regimes, while offering superior temporal and spatial precision.

Paving the way for a refined manufacturing process

With this research, EPFL contributes valuable insights to the field of laser additive manufacturing. The findings have significant implications for potential industrial applications, particularly in sectors like aerospace and precision engineering. Reinforcing Switzerland's reputation for meticulous craftsmanship and manufacturing accuracy, the study underscores the need for consistent manufacturing techniques. Furthermore, it suggests the potential for early detection and correction of defects, enhancing product quality. Logé concludes, "This research paves the way for a better understanding and refinement of the manufacturing process, and will ultimately lead to higher product reliability in the long term."

Text: Based on a press release from EPFL/ Michael Mitchell with modifications from Paul Scherrer Institute / Miriam Arrell

© PSI provides image and/or video material free of charge for media coverage of the content of the above text. Use of this material for other purposes is not permitted. This also includes the transfer of the image and video material into databases as well as sale by third parties.

Contact

Dr. Steven Van Petegem

Structure and Mechanics of New Materials

Paul Scherrer Institute PSI

+41 56 310 25 37

steven.vanpetegem@psi.ch

Original Publication

Harmonizing Sound and Light: X-Ray Imaging Unveils Acoustic Signatures of Stochastic Inter-Regime Instabilities during Laser Melting.

Hamidi Nasab, M., Masinelli, G., de Formanoir, C., Schlenger, L., Van Petegem, S., Esmaeilzadeh, R., Wasmer, K., Ganvir, A., Salminen, A., Aymanns, F., Marone, F., Pandiyan, V., Goel, S., & Logé, R. (2023).

Nature Communications, Online, 5. December 2023

DOI: 10.1038/s41467-023-43371-3