Researchers at the Paul Scherrer Institute PSI in Villigen, Switzerland, have developed a new catalytic converter for cleaning emissions from natural gas engines. In contrast to previous catalytic converters, it is very active even at low temperatures and remains that way over a long period of time. This makes it possible to burn natural gas in a cleaner and more climate-friendly way. Thus natural gas and biogas become still more attractive as substitutes for petroleum products – for example, as fuel for passenger cars. The trick lies in the substrate material of the catalytic converter, whose structure resembles a sponge. The researchers report on their development in the latest issue of the online journal Nature Communications.

Natural gas engines are expected to smooth the way to greater climate protection. They can be used to produce electric power from gas. Considered as a bridge technology in transportation, they are expected to replace petroleum-based automobile engines, which emit around one-third more carbon dioxide, until electric cars and the attendant infrastructure are fully developed. Especially climate-friendly is a gas engine that runs on biogas instead of fossil natural gas. Since in Switzerland biogas is produced exclusively from organic waste, it is a renewable and thus largely climate-neutral resource.

In practice, though, there is still one problem: The best option for combustion of natural gas is actually the so-called lean-burn engine. It adds large quantities of air to the gas in the combustion chamber to reduce the amount of fuel needed. Lean-burn engines are also especially efficient. They are being introduced mainly in gas power plants, as well as in ships and in some large lorries. Not, however, in cars. The disadvantage is that they don't burn the fuel as thoroughly as natural gas motors with less admixture of air: In the combustion of natural gas or biogas, really large amounts of its main component, methane, are left over. In addition, toxic formaldehyde is produced

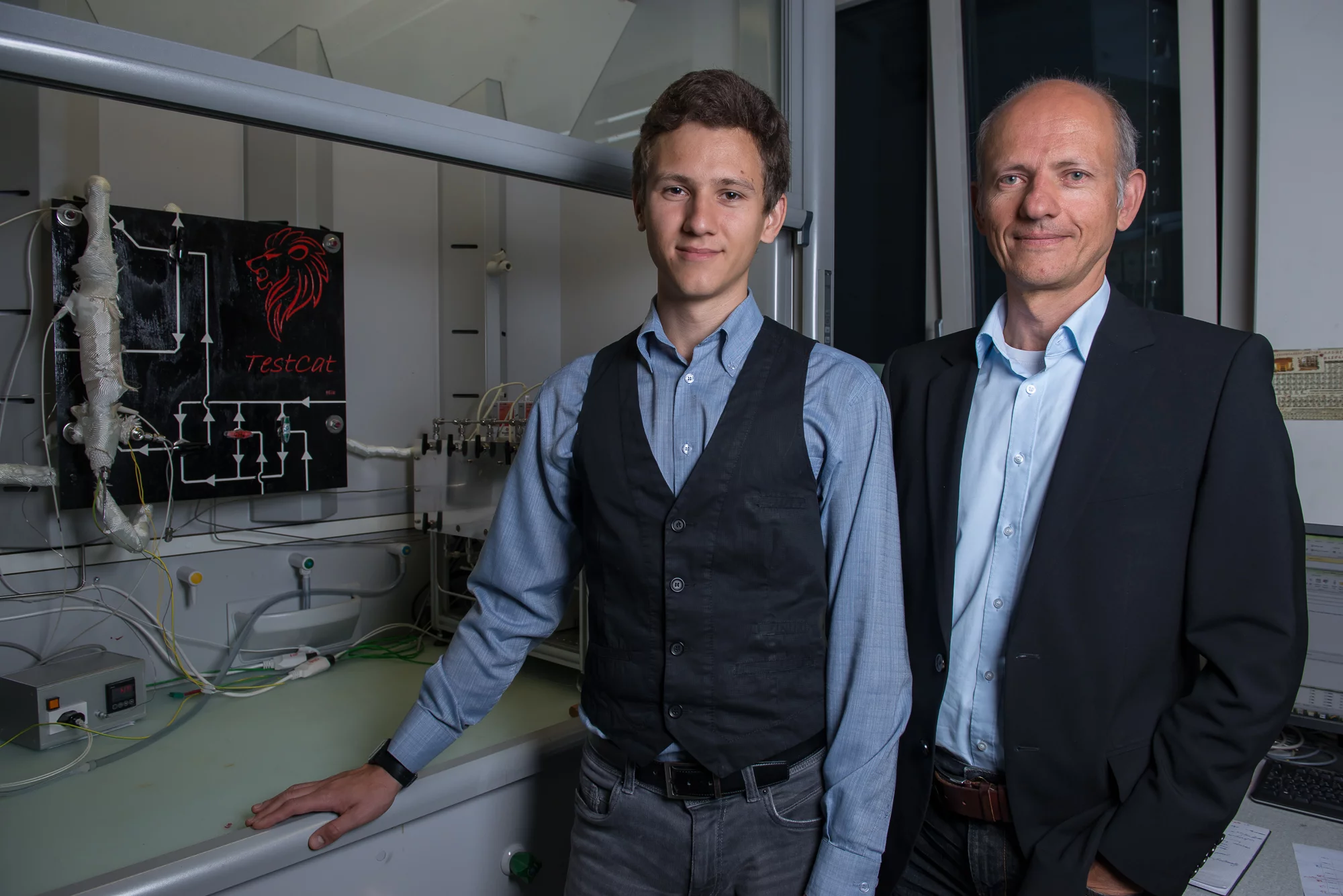

, says Oliver Kröcher, head of the Laboratory for Bioenergy and Catalysis at the Paul Scherrer Institute PSI.

PSI catalytic converter treats emissions more thoroughly

Methane is a highly potent greenhouse gas, with a climate-warming effect 25 times greater than that of carbon dioxide. Thus the emission of methane should be avoided – and likewise that of other harmful substances. For that purpose, catalytic converters have been installed that convert the pollutants into less harmful substances through chemical reactions before these get into the environment. These catalytic converters are mostly based on the noble metal palladium. In an atomically fine distribution over a rough and therefore large surface of a substrate, the palladium can react effectively with the exhaust and break down the pollutants. Up to now, aluminium oxide has normally served as the substrate material.

But in lean-burn engines in particular, this technology does not yet work optimally: Conventional catalytic converters are still not active enough in lean-burn engines at temperatures below 400 degrees Celsius

, says Kröcher. Lower exhaust temperatures are advantageous, though, because they mean more energy can be put into the actual work of the engine; thus the efficiency factor is higher. In addition, previous catalytic converters quickly suffer a decline in performance: On aluminium oxide, palladium vitrifies very rapidly in hot exhaust gases. This means that the tiny palladium particles coalesce into larger ones, like chocolate flakes in the sun. Thus their surface area is reduced and the catalytic converter suffers a corresponding loss in activity already, in fact, within a few hours in the laboratory

, according to Kröcher.

It is precisely this disadvantage that his research group has now been able to remedy: The team has developed a catalytic converter for lean-burn engines that runs stably and treats the exhaust effectively even at low temperatures.

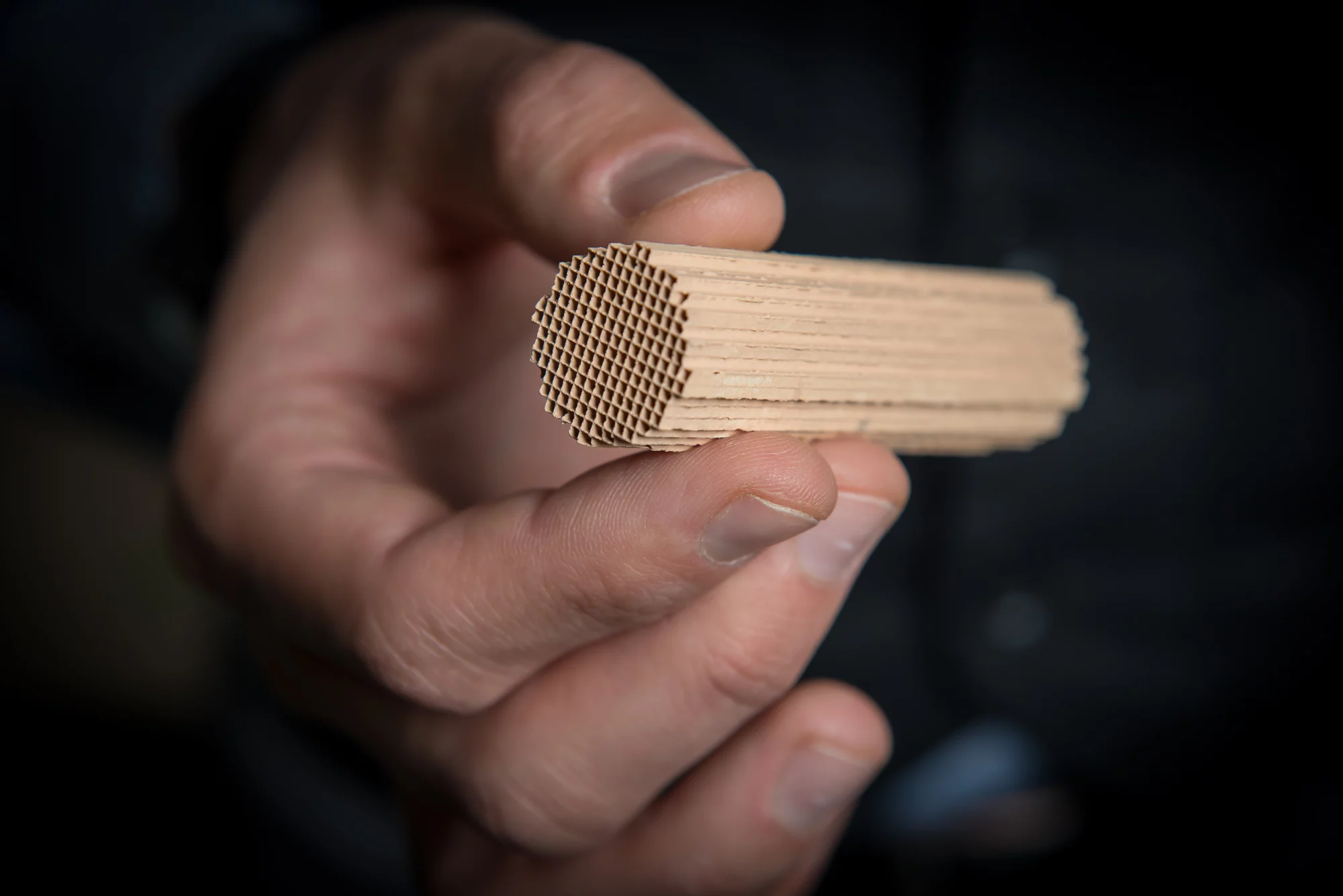

The material structure resembles a sponge

The researchers tested zeolites as new substrate materials. These are highly porous substances based on silicon dioxide. Under the microscope, they look like a sponge: pervaded by tiny holes that are connected to each other by channels. Such a structure provides an enormous amount of surface area. If the palladium is finely distributed within it, it can react still more actively with the exhaust gases, and the catalytic converter is more effective – even at low temperatures.

Other people have hit on the idea of using the zeolite

, reports Andrey Petrov, a doctoral candidate at PSI and first author of the study – only to find, however, that the palladium vitrifies anyway and loses effectiveness in the long run. It wanders through the channels to the surfaces of the zeolite and coalesces there. But Petrov had the crucial idea of how to prevent this: He treated the zeolite with acids and bases so that the pores were enlarged a bit and then added sodium to the palladium. In these larger pores, the palladium can now collect and fill them in. As we determined, it shows the strongest activity in this still nanometre-scale particle size.

At the same time, the sodium prevents the particles from migrating. Thus the catalytic converter almost completely ceases to vitrify. In our laboratory tests, the increased activity was preserved for more than 90 hours

, Oliver Kröcher confirms. And we achieved equal emission control levels at temperatures that were at least 50 degrees below those of conventional catalytic converters.

A technology with a future

Thus the emission of pollutants from lean-burn engines can be reduced significantly with the new catalytic converter – far enough, with further development work, that this type of engine could be considered for installation in normal cars. Currently, the engines of natural gas automobiles still function according to a different principle, just because up to now the secondary exhaust treatment is too ineffective

, says Kröcher. But that could change now.

Soon, it might also need to, because in policy circles there's talk of further tightening the threshold values for pollutants in engine emissions. The new method developed at PSI could help meet these standards. A patent has already been filed. The first catalyst manufacturer have already expressed an interest.

Contact

Original Publication

-

Petrov AW, Ferri D, Krumeich F, Nachtegaal M, van Bokhoven JA, Kröcher O

Stable complete methane oxidation over palladium based zeolite catalysts

Nature Communications. 2018; 9(1): 2545 (8 pp.). https://doi.org/10.1038/s41467-018-04748-x

DORA PSI

About PSI

The Paul Scherrer Institute PSI develops, builds and operates large, complex research facilities and makes them available to the national and international research community. The institute's own key research priorities are in the fields of future technologies, energy and climate, health innovation and fundamentals of nature. PSI is committed to the training of future generations. Therefore about one quarter of our staff are post-docs, post-graduates or apprentices. Altogether PSI employs 2300 people, thus being the largest research institute in Switzerland. The annual budget amounts to approximately CHF 450 million. PSI is part of the ETH Domain, with the other members being the two Swiss Federal Institutes of Technology, ETH Zurich and EPFL Lausanne, as well as Eawag (Swiss Federal Institute of Aquatic Science and Technology), Empa (Swiss Federal Laboratories for Materials Science and Technology) and WSL (Swiss Federal Institute for Forest, Snow and Landscape Research). (Last updated in June 2025)