Researchers at the Paul Scherrer Institute PSI have observed the mechanical processes in solid-state batteries more precisely than ever before. Using X-ray tomography, they discovered how fissures in the battery material propagate. The insights can help to make batteries for electric cars or smartphones safer and more efficient. The results were obtained with the help of the Swiss Light Source SLS and have recently been published in the scientific journal Advanced Energy Material.

From microchips and mobile phones to electric cars: For all this, modern society needs batteries. They should store as much energy as possible and be lightweight, safe for everyday use, and rechargeable in a short time. So far, these numerous requirements have been best met by lithium-ion batteries.

However, batteries of this type can hardly be improved any further. In addition, the liquid electrolytes used for charge transport in these batteries are flammable. Solid-state batteries, on the other hand, offer greater safety and other advantages. Here, the liquids are replaced by solid electrolytes that can withstand higher voltages and operating temperatures. Solid-state batteries can therefore be charged and discharged more quickly. They also store more energy per unit of weight.

Automakers in particular are therefore interested in optimising solid-state batteries. So far, however, the exact mechanisms that occur in such batteries are not well understood. For example, engineers do not yet know what happens inside them during charging and discharging. "In order to further develop solid-state batteries, we have to understand the electromechanical processes that occur within them", explains Xiaohan Wu, who carried out the research as part of his doctoral work in the Battery Materials and Diagnostics Research Group at the Paul Scherrer Institute PSI. In a joint project with the automotive manufacturer Toyota, PSI researchers have now advanced a critical step closer to this goal.

Cracks obstruct the path of ions

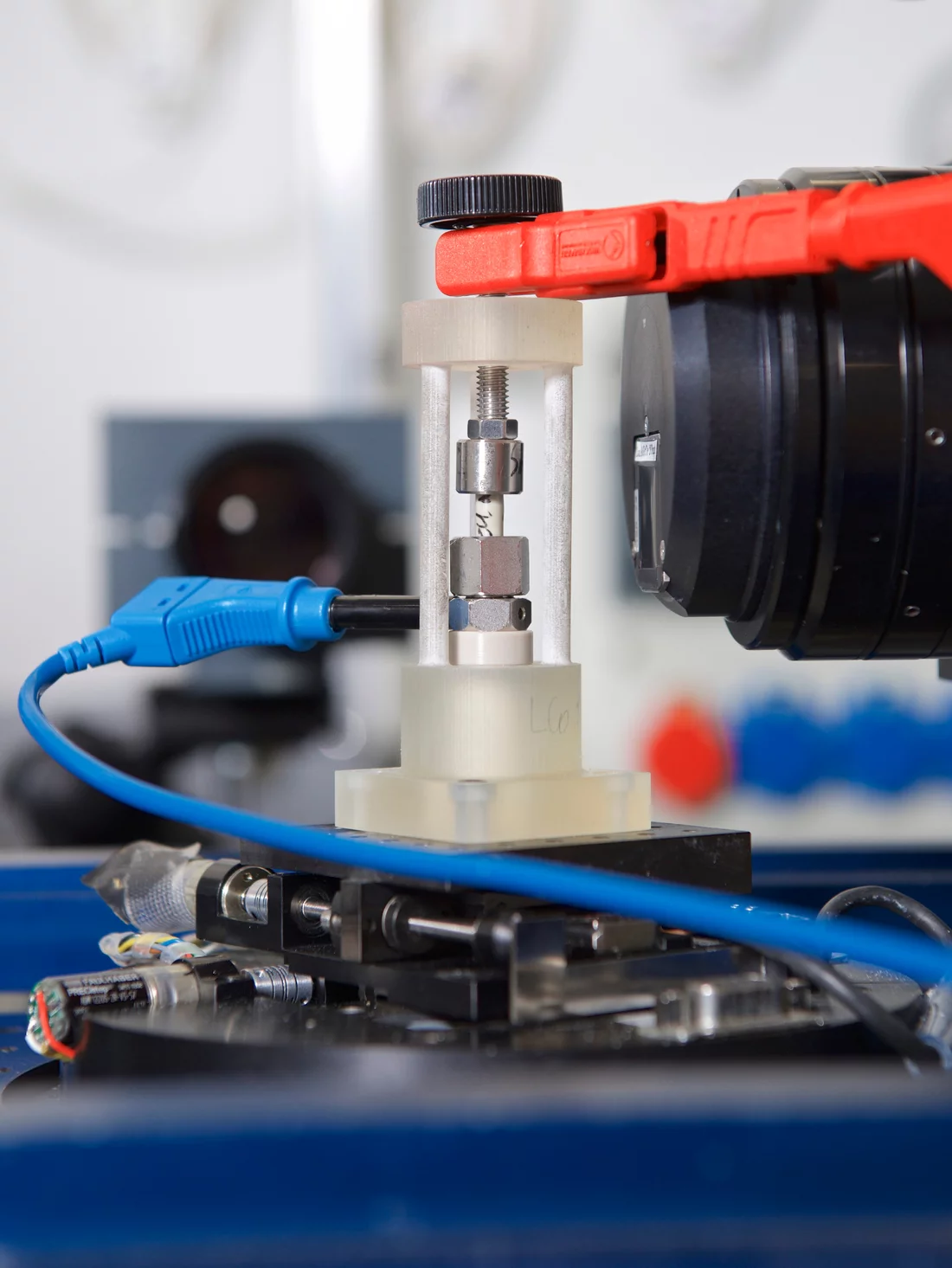

The interior of the investigated solid-state battery consists mainly of the solid electrolyte, a lithium and phosphorus sulphide. Small tin pellets with a diameter of about 30 micrometres, half as thick as a human hair, are embedded in it. When the battery is charged, lithium ions are deposited in the tin pellets. The lithium is forced into the lattice structure of the tin. The volume of the pellets grows, and they expand. This causes the surrounding electrolyte material to fracture. The resulting cracks then hinder the movement of lithium ions through the electrolyte, which significantly reduces the performance of the solid-state battery.

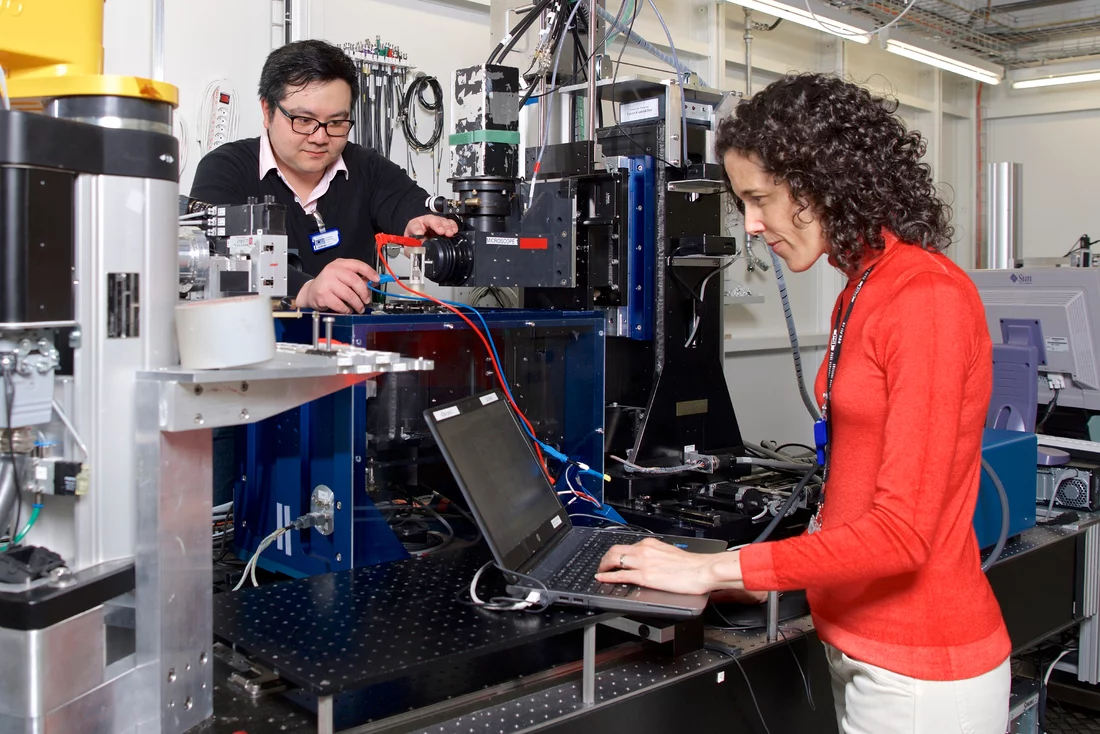

Using so-called operando X-ray tomographic microscopy at PSI's Swiss Light Source SLS, the researchers have now succeeded in precisely observing such processes during battery operation. "The method works in principle like computer tomography in a hospital, but the photon flux at the PSI synchrotron is several orders of magnitude higher", explains beamline scientist Federica Marone, who helped refine the method and was responsible for the technical implementation at the SLS beamline TOMCAT, which was used for the study. "This allows us to achieve the necessary spatial and temporal resolution to track processes within the battery during operation.”

The researchers continuously monitored the battery during charging and discharging. On the basis of the pictures they recognised that the tin pellets expand up to roughly 300 percent. They were also able to see how the cracks in the electrolyte spread. "We didn't expect the cracks to spread in such a way that they would exactly traverse the lithium ions' path through the battery cell", says Xiaohan Wu. As a result, the ions have to make extreme detours, which greatly inhibits the charging and discharging process.

The material heals itself

The researchers also found that the battery virtually repairs itself when discharged. When the lithium ions migrate out of the tin pellets, the cracks in the surrounding electrolyte close again. "The solid electrolyte is elastic, so it can self-heal", explains Wu. The next step in this research is to find other electrolyte materials that react to the expansion of the tin spheres to a smaller extent.

"The results of this study provide the automotive industry with important information for the development of robust and efficient solid-state batteries", says Xiaohan Wu. The researchers have now published their results in the journal Advanced Energy Material.

Text: Paul Scherrer Institute/Christina Bonanati

Additional information

Towards on-the-fly data post-processing for real-time tomographic imaging at TOMCAT

Marone F, Studer A, Billich H, Sala L, Stampanoni M.

Advanced Structural and Chemical Imaging, 2017

Surface and morphological investigation of the electrode/electrolyte properties in an all-solid state battery using a Li2S-P2S5 solid electrolyte.

Wu X, El Kazzi M, Villevieille C.

Journal of Electroceramics, 2017

Contact

Dr. Federica Marone

Beamline Scientist, X-ray tomographic microscopy

Paul Scherrer Institute, Forschungsstrasse 111, 5232 Villigen PSI, Switzerland

Telephone: +41 56 310 53 18, e-mail: federica.marone@psi.ch

Original publication

Operando visualization of morphological dynamics in all-solid-state batteries

X. Wu, J. Billaud, I. Jerjen, F. Marone, Y Ishihara, M. Adachi, Y. Adachi, C. Villevieille, Y. Kato

Advanced Energy Material, 30 July 2019 (online)

DOI: 10.1002/aenm.201901547