(with the Laboratory for Neutron and Muon Instrumentation and the Laboratory for Neutron Scattering and Imaging, in CNM)

Multiferroicity has sparked in the last few years a lot of interest in solid state physics. From an application point of view it is desirable to control charges by applying a magnetic field and spins by an electric field. From a physics point of view an important question to answer is how the coupling between ferroelectricity and magnetism in solids is achieved: magnetism is related to an ordering of spins (electrons) in incomplete ionic shells, ferroelectricity mostly results from a relative shift of negative and positive ions. Early attempts to combine ferroelectricity and magnetism proved to be difficult because the microscopic mechanisms of ferroelectricity and magnetism are quite different and do not strongly interfere with each other. Only recently, materials like REMnO3, REMn2O5 (RE: rare earths), Ni3V2O8, CuFeO2 (delafossite), (Co,Ni)Cr2O4 (spinel), MnWO4, and hexagonal ferrite (Ba,Sr)2Zn2Fe12O22 have shown multiferroic properties. Most of these materials are low-dimensional or frustrated magnets with strong magnetic fluctuations. The reason for the sensitivity of the dielectric properties to an applied magnetic field lies in the magnetic origin of their ferroelectricity, which is induced by complex spin structures, characteristic for frustrated magnets. This spin structure can be investigated using neutrons like the low-temperature spiral phase which breaks the inversion symmetry and hence allows an electric polarization [2].

The electric field E, magnetic field H, and stress σ control the electric polarization P, magnetization M, and strain ε, respectively. In a ferroic material, P, M, or ε are spontaneously formed to produce ferromagnetism, ferroelectricity, or ferroelasticity, respectively. In a multiferroic, the coexistence of at least two ferroic forms of ordering leads to additional interactions. In a magnetoelectric multiferroic, a magnetic field may control P or an electric field may control M (green interaction arrows) [1].

- Spaldin and Fiebig. Science 309, 391 (2005)

- Kenzelmann et al., PRL 95, 087206 (2005)

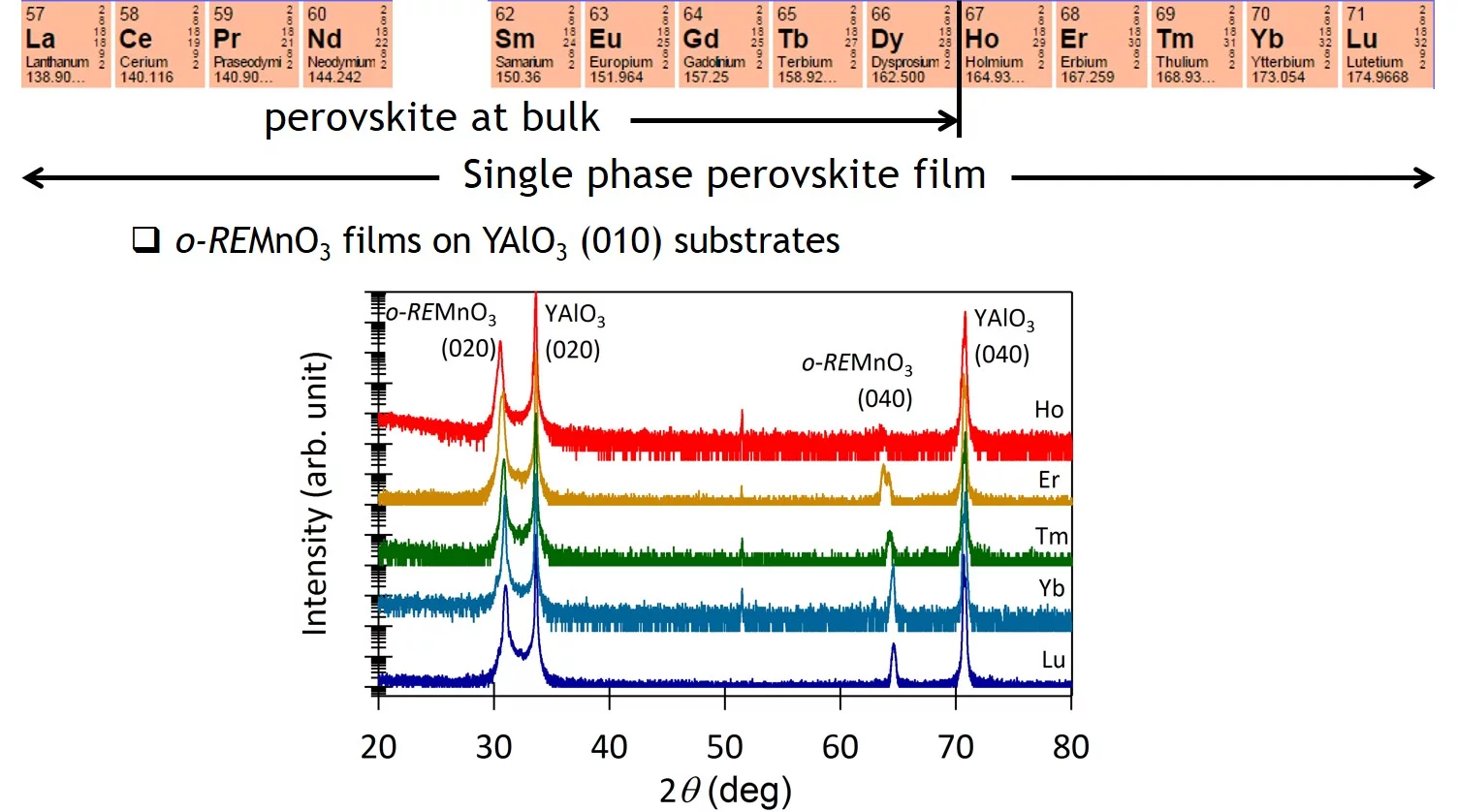

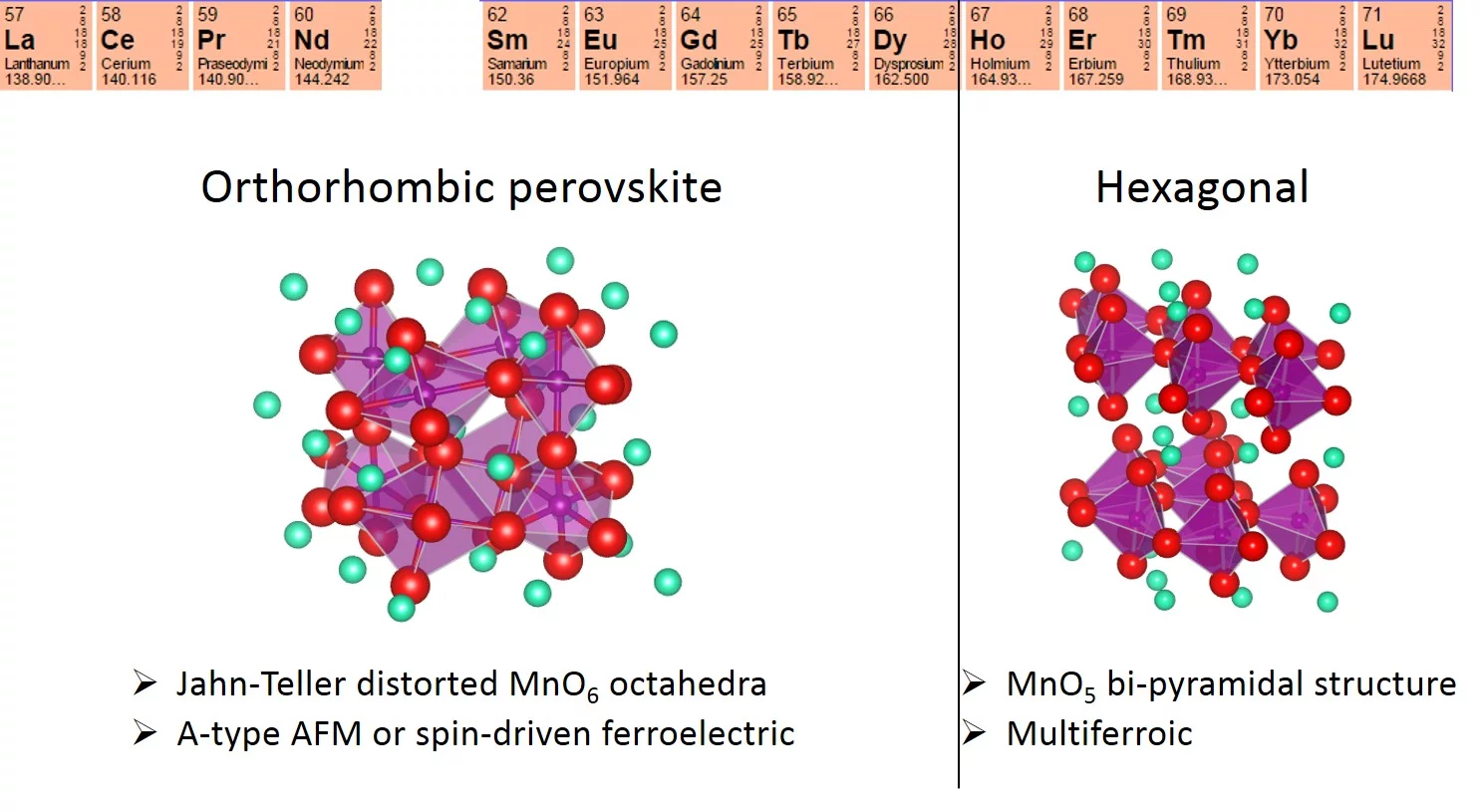

Our main interest is directed towards the multiferroic properties of magnetically induced ferroelectric materials prepared as thin films, in particular under the influence of growth-induced strain due to epitaxy, called epitaxial strain. Utilizing the epitaxial strain, we try to improved or search for hidden multiferroic functionalities. Our recent focus has been on orthorhombic REMnO3 with RE=Gd-Lu. Bulk REMnO3 with RE=Gd-Dy have an orthorhombic structure when prepared at ambient conditions. On the other hand REMnO3 with RE=Y-Lu are hexagonal and become orthorhombic by high-pressure synthesis. The magnetic ground state is antiferromagnetically ordered. From RE=Gd, it is an A-type, RE=Tb,Dy show a cycloidal structure, Y and Ho are described as incommensurate sinusoidal, and RE=Er-Lu are E-type. Each magnetic order induces distinct electric properties: paraelectricity from A-type order, magnetically switchable ferroelectricity from a cycloidal structure, and magnetically robust ferroelectricity from E-type order.

The first implementation of epitaxy on REMnO3 is to stabilize the metastable orthorhombic phase for RE=Ho-Lu. By growing these compounds on ABO3 perovskite substrates e.g. YAlO3, the orthorhombic REMnO3 phase is forced to form on the substrate surface. The next figure shows one example for (010) oriented orthorhombic REMnO3 thin films (RE=Ho-Lu) grown on (010) oriented YAlO3 substrates. So far, there is no means to grow large bulk single crystalline REMnO3 for RE = Er – Lu. Epitaxial film growth shown here is at present the only technique to obtain at least large areas single-crystalline material with thicknesses ranging from a few nm up to several 100nm.

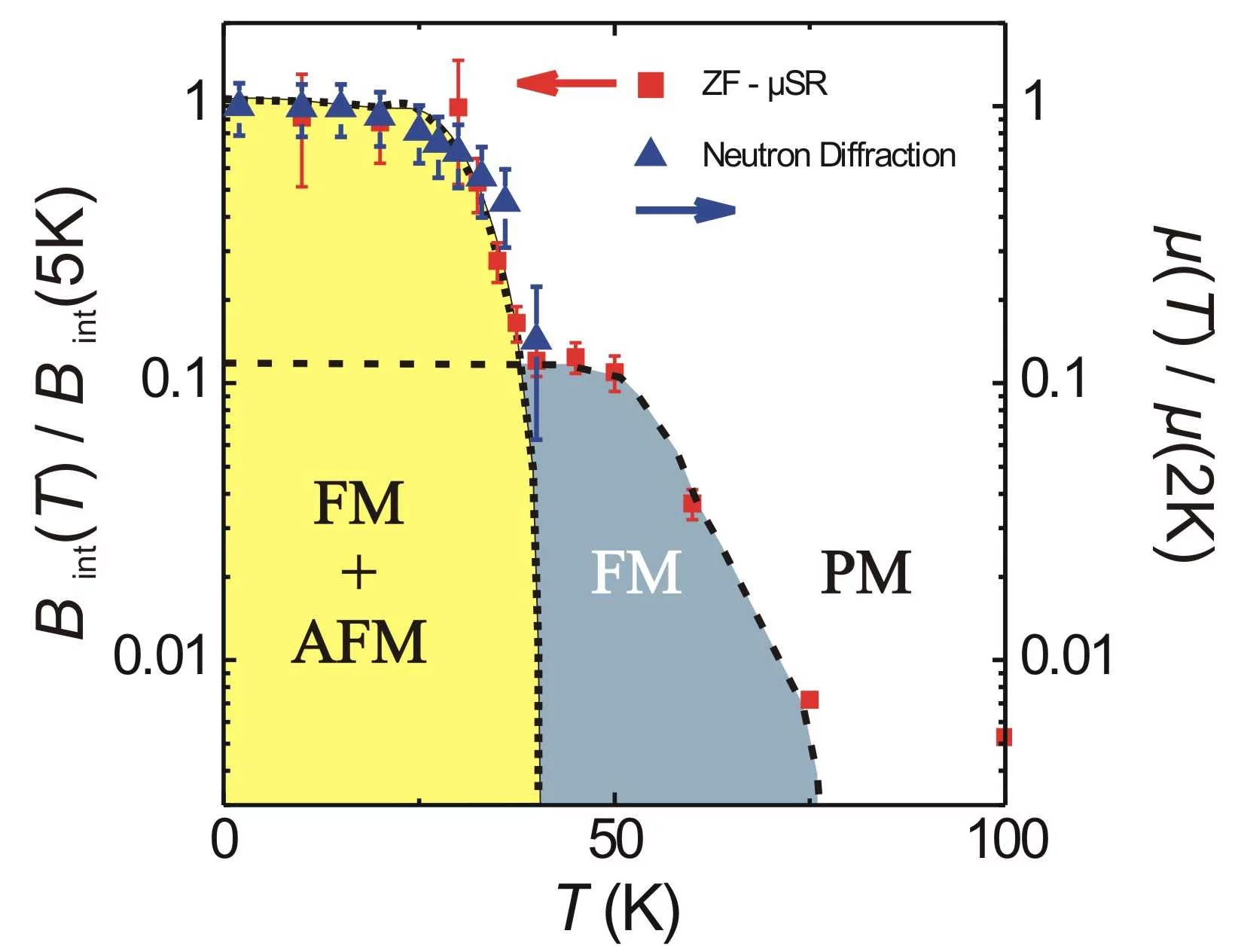

Epitaxial strain induces various exotic changes in multiferroic properties of REMnO3. For example, a LuMnO3 film epitaxially grown on a (110) oriented YAlO3 substrate is shown to exhibit ferromagnetism at film-substrate interface (for ca. 10 nm) along with an antiferromagnetic layer on top [3]. It is assumed that massively strained layer induces ferromagnetism in LuMnO3 [3] and we succeeded to make an inherent ferromagnetic-antiferromagnetic heterostructure in a single composite. Polarized neutron reflectometry (PNR), muon spin spectroscopy, and neutron diffraction measurements are performed to reveal the properties as shown in the next figure where the magnetic phasediagram of (110) LuMnO3 has been mapped [4]. This was done in collaboration with the Laboratory for Neutron Scattering and Imaging and the Laboratory for Muon Spin Spectroscopy. Other drastic changes are also achievable, e.g., enhancement of transition temperatures and changes of the antiferromagnetic order e.g. in HoMnO3 [5].

3. White et al., PRL 111, 037201 (2013)

4. Schneider et al., PRB 94, 054423 (2016)

5. Shimamoto et al., APL 108, 112904 (2016)

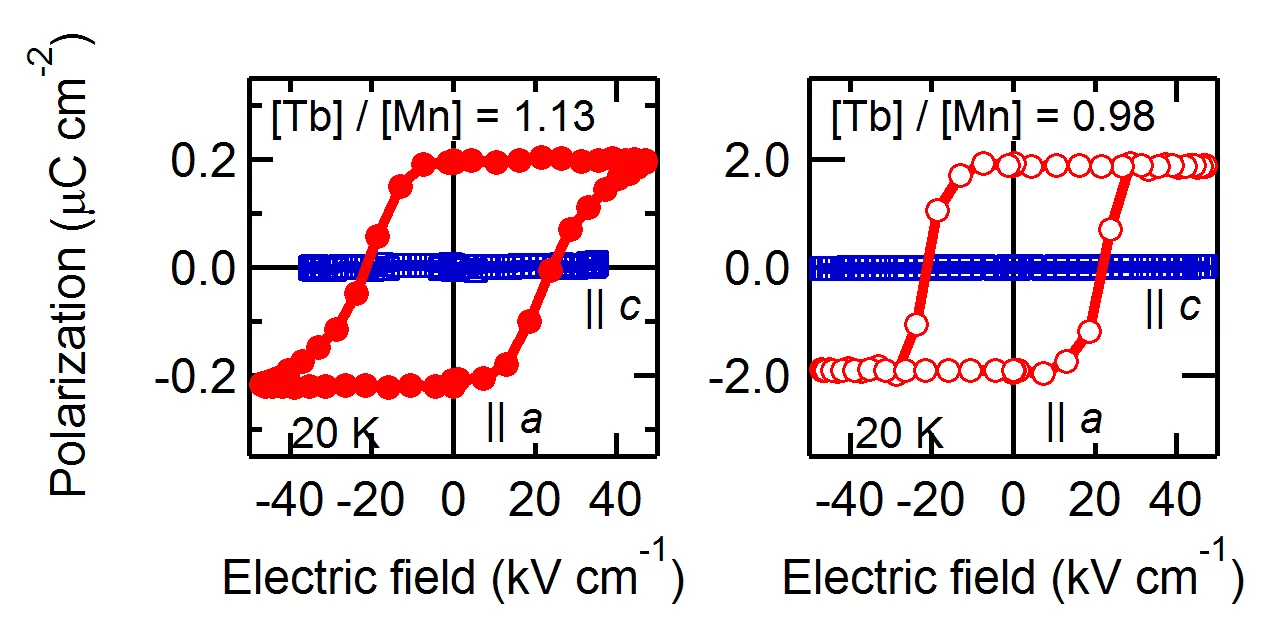

In order to examine the influence of epitaxial strain, it is necessary to obtain films of a chemically high quality. The deviation of the chemical composition from the ideal value causes in these materials a significant deterioration in some of their physical properties. Ferroelectric hysteresis curves of two TbMnO3 films, Tb-rich and stoichiometric, clearly show that a chemical imperfection causes a significant deterioration of the electrical polarization. Therefore, the search for the optimum growth condition and analyses of chemical composition of films are an indispensable prerequisites for reliable research of materials with complex compositions [6].

6. Shimamoto et al., JAP 119, 184102 (2016)

![Phase control in ferroics and multiferroics. Figure has been adopted from Ref [1]](/sites/default/files/styles/primer_full_image_xxl/public/import/lmx-interfaces/MultiferroicThinFilmsEN/multiferroic_.jpg.webp?itok=wf71xP18)

![Bulk phase diagam of the orthorhombic REMnO3 family. Figure has been adopted from Ref [3]](/sites/default/files/styles/primer_full_image_xxl/public/import/lmx-interfaces/MultiferroicThinFilmsEN/REMnO3_Phase_diagram_bulk.jpg.webp?itok=xNoSvQbI)