Lasers

- KrF excimer laser (Lambda Physik LPX 300) with 900 mJ/pulse at 248 nm.

- KrF excimer laser (Lambda Physik LPX 300) with 1100 mJ/pulse at 248 nm.

- KrF excimer laser (Lambda Physik LPX 300) with 900 mJ/pulse at 248 nm.

- KrF excimer laser (Coherent LPX 201) with 750 mJ/pulse at 248nm

- XeCl excimer laser (Lambda Physik COMPex) with 400 mJ/pulse at 308 nm.

- Nd:YAG laser (Quantel Brilliant B) with 850 mJ/pulse at 1064 nm, 400 mJ/pulse at 532 nm, 160 mJ/pulse at 355 nm and 90 mJ/pulse at 266 nm.

- Ar+ laser (Coherent Innova 300C FreD), multi line, including UV (doubling of 488 nm) with 0.1 W at 244 nm.

- Ti:Sapphire (Coherent 899 Ring Laser for Raman), 680-1100 nm (line widths < 2 GHz)

Excimer lamps

Thin Film Deposition

At present, we run four ablation chambers dedicated to different deposition requirements. All chambers are serviced with the 248nm wavelength.

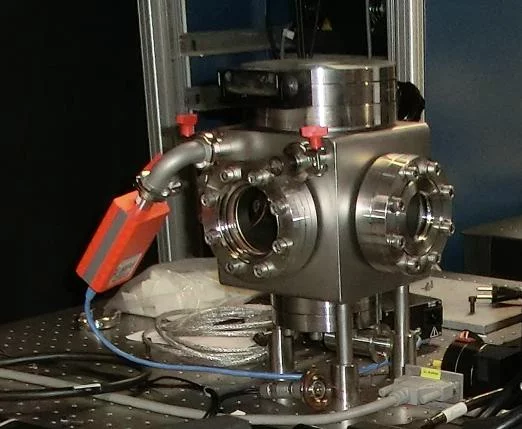

1. High vacuum chamber for pulsed laser deposition

- One cylindrical target

- Synchronized reactive gas pulse (designed and built: University Zurich)

- Quartz micro balance

- Plasma beam (designed and built at the National Institute for Lasers, Plasma and Radiation Physics, NILPRP, Romania)

- Ion (Langmuir) probe

- Usable gases for background: O2, N2O, Ar, N2, NH3, NF3

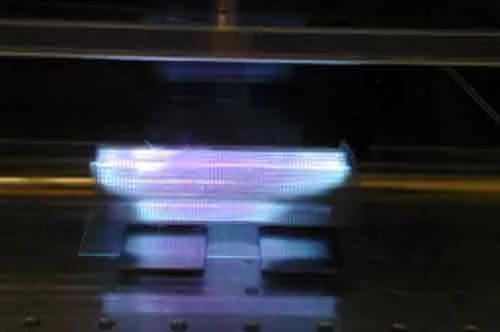

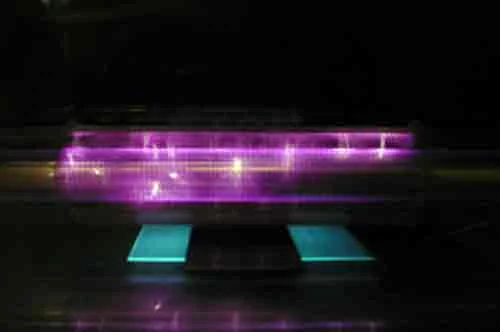

- Option for all chambers: ns-Plasma imaging at tuneable wavelengths between 400 and 1000 nm (Camera by Andor, AOTF by Brimrose)

2. High vacuum chamber for pulsed laser deposition

- One cylindrical target

- One disc target

- Option to use frozen liquids as targets (MAPLE)

- Quartz micro balance

- Usable gases for background: O2, N2O, Ar, N2

- Option for all chambers: ns-Plasma imaging at tuneable wavelengths between 400 and 1000 nm (Camera by Andor, AOTF by Brimrose)

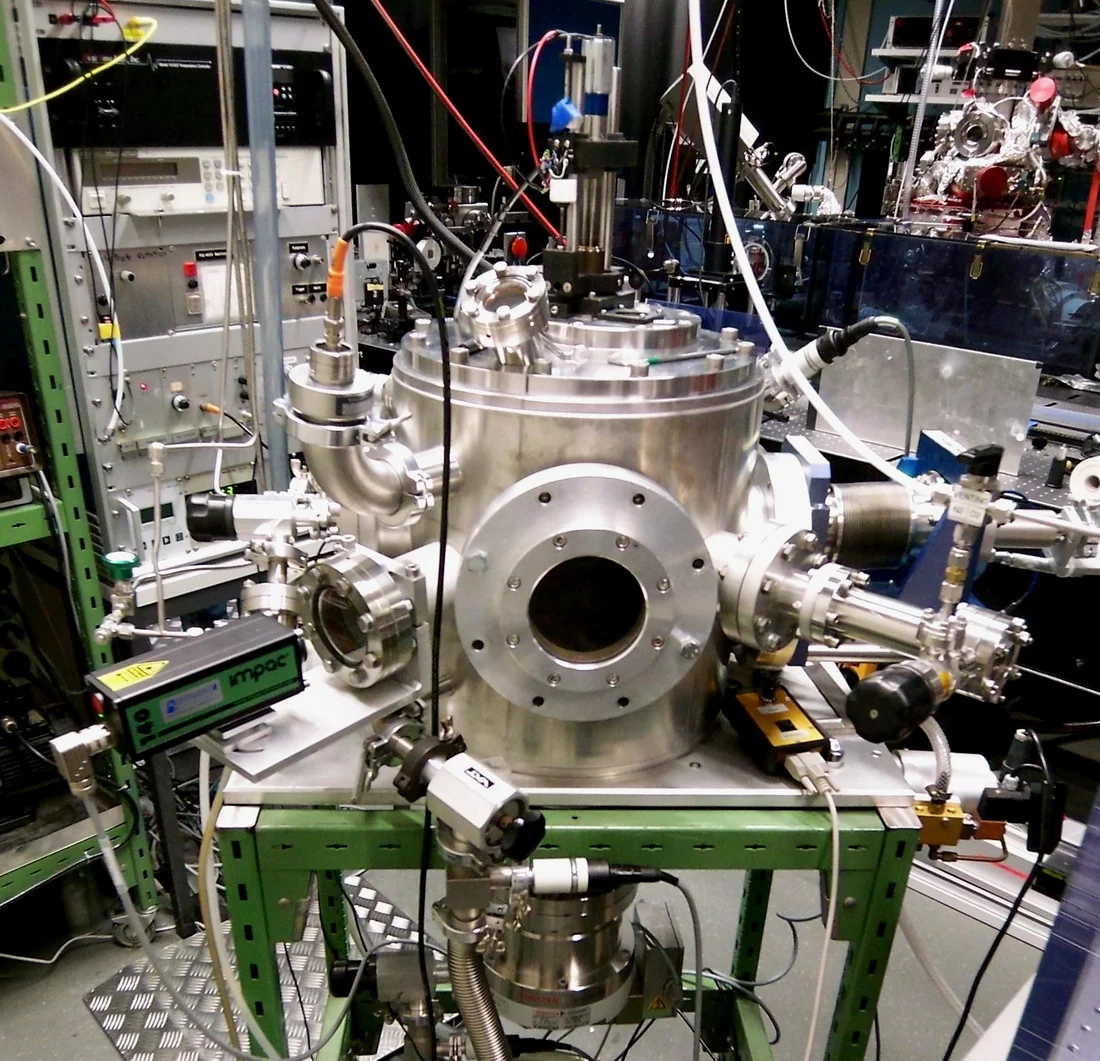

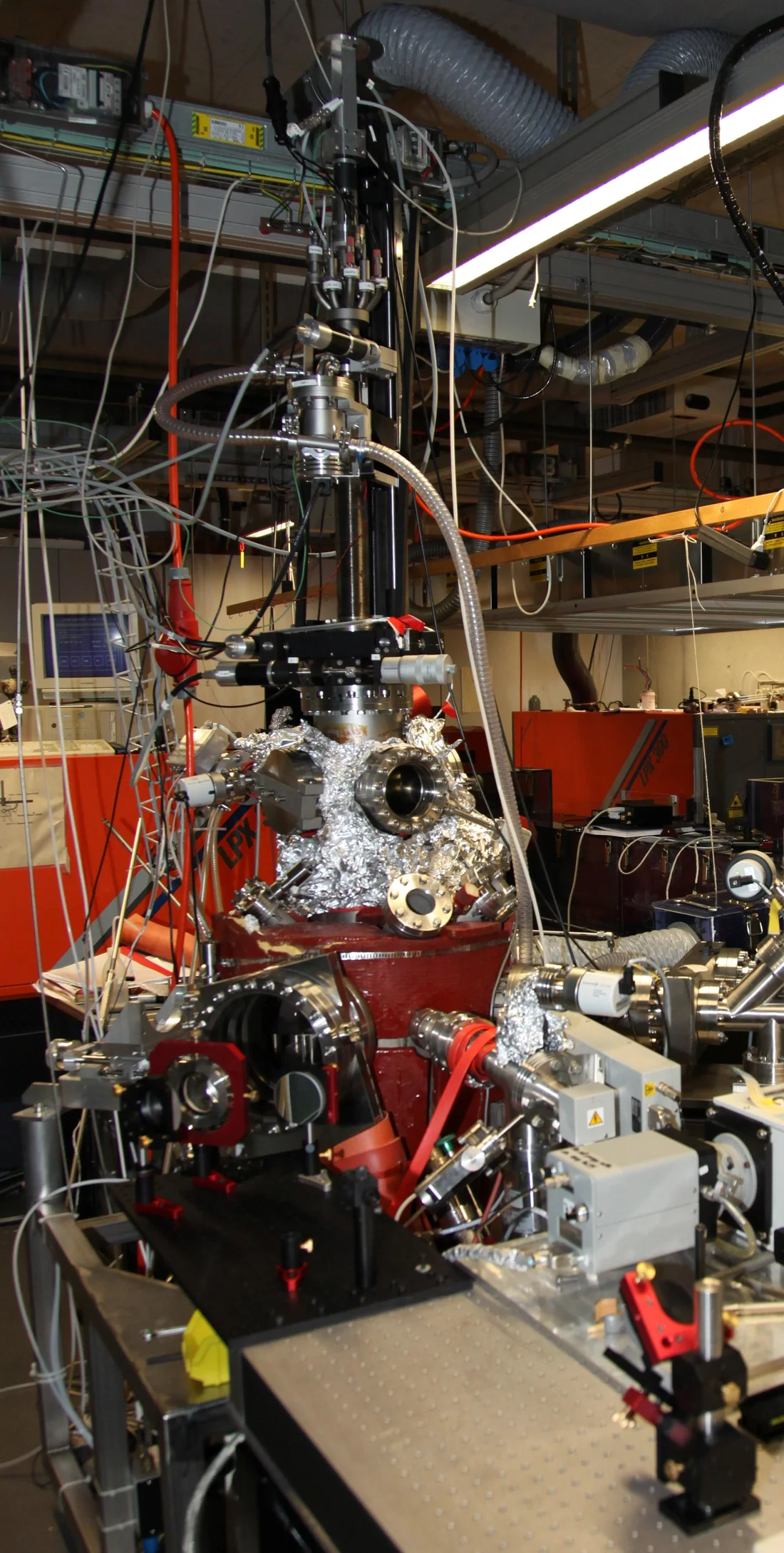

3. Ultra high vacuum chamber for pulsed laser deposition

- 5 computer controlled cylindrical targets (PSI designed and built)

- Optional: 1 computer controlled pellet target (PSI designed and built) for RT and 77K

- Computer controlled substrate manipulator with x,y,z and 2 rotational movements for temperatures from 120 K to 1100 K (designed and build by PREVAC)

- Substrate holder for heating and cooling, applicable for pulsed laser deposition (designed and build by PREVAC) for temperatures up to 1100 K and pressure up to 1 bar (oxygen)

- Quartz micro balance (mechanical design from PREVAC, Oscillator, PLO-10i from BeamTec-MaxTec)

- Synchronized reactive gas pulse (University Zurich designed and built)

- Plasma beam (designed and built at the National Institute for Lasers, Plasma and Radiation Physics, (NILPRP), Romania and modfied for UHV at PSI)

- Ion-probe (distance and angle resolved) (PSI designed and built, probe built at Risoe National Institute, Denmark)

- Meta-stable detector (distance and angle resolved) (PSI designed and built)

- Plasma analysis using a mass spectrometer (energy, distance, time and angle resolved; EQP-from Hiden) also utilized for SIMS

- Ion gun for in-situ SIMS analysis with flood gun (IG 20 from Hiden, flood gun by PREVAC)

- Load-lock system with battery pumped transfer vessel (from PREVAC)

- Optical plasma analysis of the laser induced emission spectrum with time and space resolution using a gated-ICCD connected to a high resolution monochromator with various gratings (150 up to 1800 lines per inch) for wavelengths between 200 and 900 nm

- Optical plasma analysis of the laser induced emission spectrum using an imaging set-up. The camera provides time (ns) and spatial resolution (mm), the acusto-optical filters (AOTF) a frequency resolution between 400 and 1000 nm.

- Usable gases for background: O2, N2O, Ar, N2

- Option for all chambers: ns-Plasma imaging at tuneable wavelengths between 400 and 1000 nm (Camera by Andor, AOTF by Brimrose)

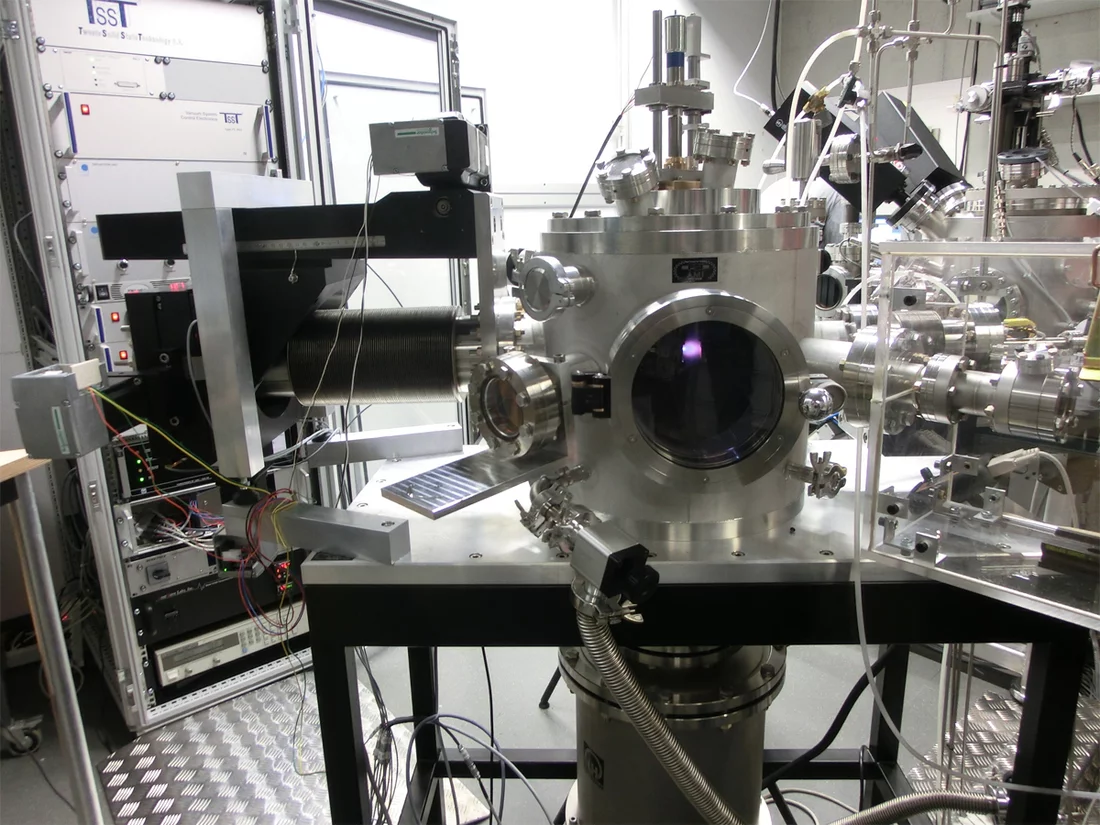

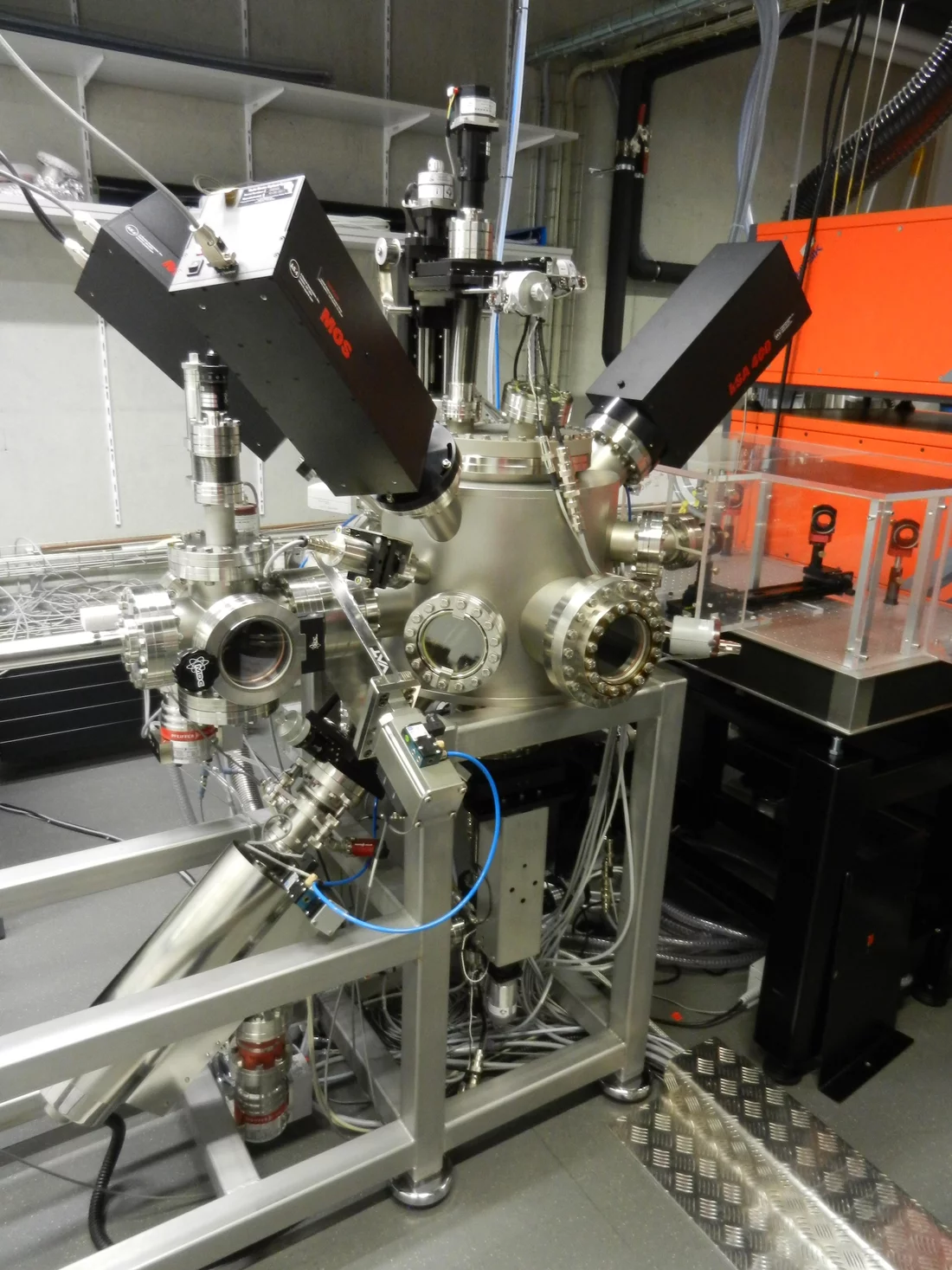

4. Ultra high vacuum chamber for pulsed laser deposition (design and build by TSST)

Sample preparation

- Precision polishing/lapping (Unipol 801, MTI Corporation)

- Spin coater with dispenser (SCS P6708)

- Draw blade applicator for film master blading

- High speed mixing (Ika, Ultra-Turrax T25)

Analysis

1. Techniques for analysis after irradiation

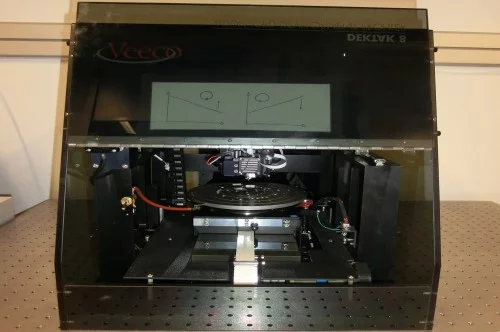

- Profilometer (Veeco, Dektak 8) for measurements of surface profiles and roughness.

- Scanning electron and standard optical (video) microscopy

- Raman-microscopy (imaging, Jobin Yvon): with a highest spatial resolution of 1 micron3. Sample heating up to 1200 K under inert gas is also possible.

- High resolution Raman spectroscopy: possible for different laser lines (Ar+ laser + RingLaser, see above) and measurements close to the Raleigh line ~ 5-10 cm-1) and temperatures from 4 K to 300 K.

- X-ray diffraction (XRD, Siemens D500, Cu anode) for standard θ-2θ and small angle reflectometry.

- Seifert diffractometer (four circle, Cu Kα1). Booking page

- Optical plasma analysis (Laser induced emission (breakdown) spectroscopy or LIBS) by time integration of the emission spectrum. This non-vacuum spectroscopic technique is used e.g. for a trace element analysis of the laser induced plasma.

- Dynamic and static SIMS (Hiden EQS) with argon and oxygen ions. Best lateral resolution 100 microns; depth profiling and compositional analysis.

- Quartz micro balances for measurement of ablation or deposition rates.

- UV/Vis/near-IR Spectrometer (Varian Cary 500) to measure diffuse reflectance (Labsphere, DRA-CA-50) and transmission.

- Hall measurement system (Ecopia HMS 3000) at RT and 77 K with 0.5 Tesla magnet.

- Keithley current source, voltmeter for R(T) measurements

- Agilent LCZ-meter - ε(T)

2. Time-resolved (ns to ms) analytical techniques

- Optical plasma analysis of the laser induced emission spectrum using an imaging set-up. The camera provides time (ns) and spatial resolution (mm), the acusto-optical filters (AOTF) a frequency resolution between 400 and 1000 nm.

- Ion probes (Langmuir probes) for plasma analysis (time, space and angle resolved)

- Plasma analysis using a mass spectrometer (energy, distance, time and angle resolved; EQP-from Hiden)