Hypo-eutectoid carbon steels are attractive for laser powder bed fusion (L-PBF), but their fast heating/cooling and repeated reheating make the microstructure hard to predict. In this study, researchers from PSI and Chalmers University combined real-time synchrotron X-ray diffraction at the MS beamline of the Swiss Light Source with targeted simulations to map, in detail, how structure and carbides evolve during processing—clarifying the solidification path, the martensitic transformation, and the short, cyclic tempering known as the intrinsic heat treatment (IHT).

Additive manufacturing by laser powder bed fusion (LPBF) is increasingly used to produce metallic parts with complex geometries and tailored properties. In this process, a thin layer of metal powder is selectively melted by a scanning laser beam and rapidly solidifies to form a dense layer. Repeating this step thousands of times builds the final three-dimensional component. While this method offers remarkable flexibility, it also creates a highly complex thermal environment. Each point in the material experiences rapid heating and cooling and multiple reheating cycles as new layers are deposited. These conditions strongly affect how the internal microstructure develops and, in turn, determine the mechanical performance of the printed part.

For steels, this evolution is particularly intricate because their structure can transform several times depending on the temperature and cooling rate. In hypo-eutectoid carbon steels—those with less carbon than the eutectoid composition—different combinations of ferrite, austenite, martensite, and carbides can form depending on how fast the material cools and how often it is reheated. Predicting these transformations and diffusion processes during LPBF is difficult because the relevant time scales are extremely short, from microseconds to milliseconds.

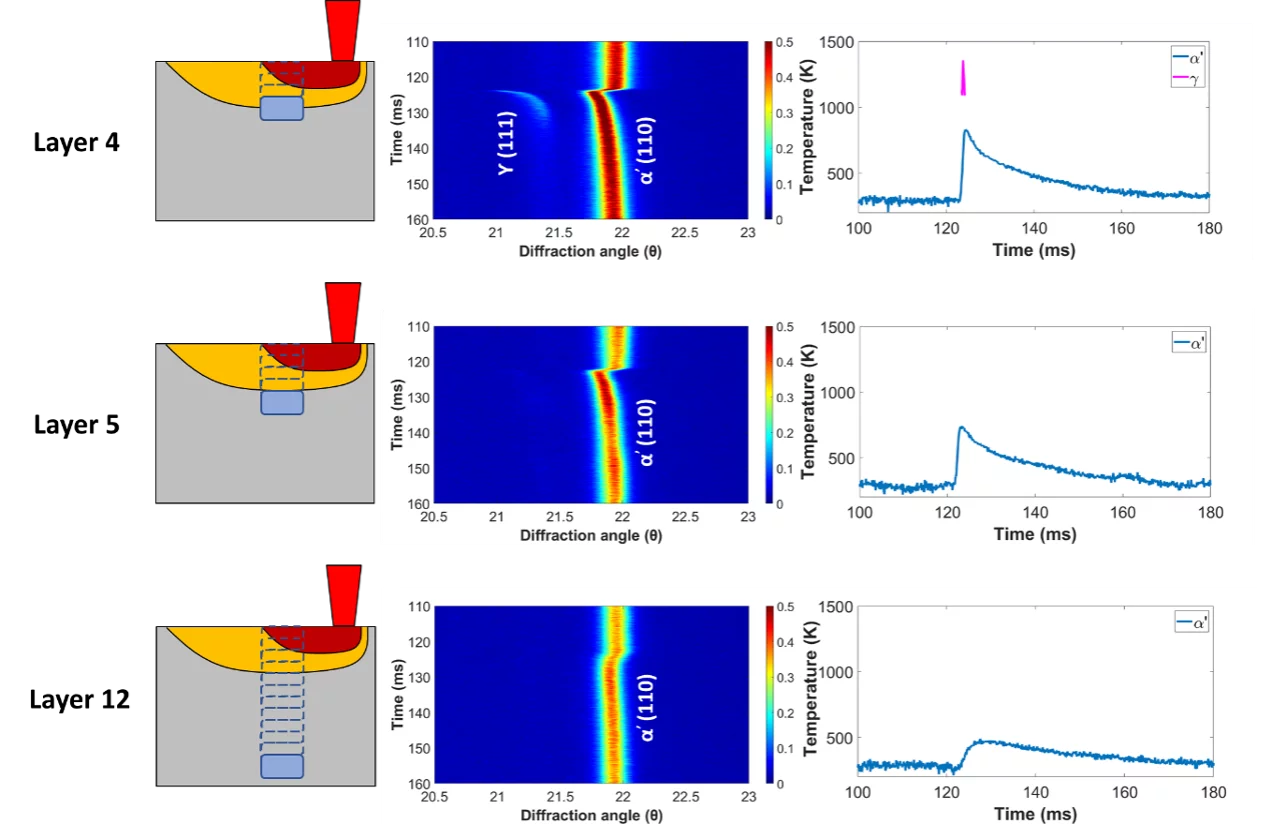

Researchers from the Paul Scherrer Institute (PSI) and Chalmers University of Technology have combined advanced in situ experiments and simulations to untangle this complexity. Using a miniaturized LPBF setup at the Materials Science (MS) beamline of the Swiss Light Source, they performed real-time synchrotron X-ray diffraction measurements on a Fe–0.45C hypo-eutectoid steel. The high brilliance and time resolution of the beamline allowed diffraction patterns to be recorded at rates up to 20,000 frames per second, revealing how the crystal structure changed during melting, solidification, and the brief reheating of previous layers.

The experiments showed that, at the cooling rates typical of LPBF—between roughly 10⁵ and 10⁶ kelvin per second—the alloy solidifies directly into austenite rather than δ-ferrite, and then transforms into martensite upon further cooling. Measurements and hardness tests confirmed a fully martensitic top layer with very high hardness, while the layers below contained tempered martensite. The repeated reheating of these underlying layers acts as an intrinsic heat treatment, or IHT, tempering the martensite and driving short bursts of diffusion and carbide formation.

Numerical simulations of temperature evolution, phase stability, and carbide precipitation were used to interpret the diffraction data. These models reproduced the observed sequence of transformations and showed that cementite becomes the dominant carbide even after only a few heating cycles. The high dislocation density and fine subgrain structure typical of LPBF accelerate diffusion and favor the rapid growth of these carbides. Most of the tempering occurs during the first few IHT cycles and then saturates as the heat dissipates more efficiently into the already solidified material.

The study provides a coherent picture of how the microstructure of hypo-eutectoid carbon steel develops during laser 3D printing. By linking time-resolved diffraction, microscopy, and simulations, the PSI–Chalmers team clarified how solidification, transformation, and short-term diffusion combine to produce a predominantly martensitic but locally tempered microstructure. These insights will help optimize process parameters and guide the design of steels specifically adapted to the extreme thermal cycles of additive manufacturing.

Contact

Dr. Steven Van Petegem

Structure and Mechanics of Advanced Materials, Center for Photon Science

Paul Scherrer Institute, Forschungsstrasse 111, 5232 Villigen PSI, Switzerland

Telephone: +41 56 310 2537, e-mail: steven.vanpetegem@psi.ch

Original publication

Phase Transformations in Hypo-Eutectoid Carbon Steel During Laser Powder Bed Fusion

W. Hearn, S. Goel, C. Pauzon, A.S. Shaikh, N. Casati, E. Hryha, S. Van Petegem

Additive Manufacturing 113 (2025) 105020

DOI: 10.1016/j.addma.2025.105020