We offer the possibility to perform a semester / master project within the framework of our existing soft and hard matter projects. Our research group is located at Paul Scherrer Institut (PSI) (by train 40 min from Zürich or 2.5 h from Lausanne). In the case of a semester project you may opt for a hybrid format working mainly from your home institution with a couple of visits to PSI during the semester. The travelling and accommodation costs will be covered. In the case of a master project, the project will be carried out at PSI (although some remote work is possible). Below a list of currently available projects.

Development of Novel TRIP Steels for Laser Powder Bed Fusion

Supervision: Dr. William Hearn, william.hearn@psi.ch

Project responsible: Dr. Steven Van Petegem (steven.vanpetegem@psi.ch / steven.vanpetegem@epfl.ch)

Keywords: Additive Manufacturing, TRIP, stainless steel

Description: Laser powder bed fusion (L-PBF) is an additive manufacturing (AM) technique where metal powder is selectively fused by a laser in a layer-upon-layer fashion to achieve a 3D structure. This unique way of manufacturing has gained large interest from industry since light weight and complex structures can be built on demand, cutting lead time, without the need of conventional material removal processes. Despite this, the number of alloys developed for the process remains limited. Additionally, the composition of the alloys is not specifically designed for L-PBF and is instead developed from what is required when using traditional manufacturing techniques.

An important alloy group that starting to receive more interest in L-PBF are martensitic stainless steels which provide a combination of corrosion resistance with high strength and hardness. Recently, it was shown that these alloys display a transformation-induced-plasticity (TRIP) effect which involves the transformation of austenite to martensite during plastic deformation. This effect is sought after as it can lead to an enhancement of both strength and ductility for the material. However, control of this TRIP effect by adjusting alloy composition or post-processing heat treatment has yet to be thoroughly explored for these alloys.

The proposed research project will focus on the development of martensitic stainless to maximize the TRIP effect for these alloys. This will require the development of:

- Suitable L-PBF parameters that produce high-density and defect free parts.

- Design and variation in alloy chemistry to optimize TRIP effect.

- Development of suitable post-processing heat treatments.

- Mechanical testing and microstructure characterization of produced parts.

The implementation of such high-quality work will be presented and published accordingly. In addition, there is the possibility to conduct experiments at large-scale facilities (e.g., synchrotron or neutron-source) related to this topic, depending on the approval of beamline proposals.

Multimodal x-ray analysis of flexible blue frog bones

Supervision: Torne Tänzer (torne.taenzer@psi.ch / torne.tanzer@epfl.ch)

Direction: Prof. Marianne Liebi (marianne.liebi@psi.ch / marianne.liebi@epfl.ch)

Keywords: X-ray scattering, synchrotron, biomechanics, biomaterials

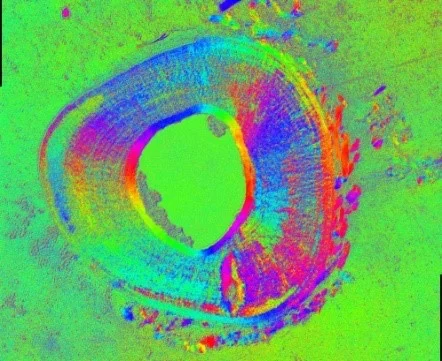

Description: We are looking for an enthusiastic and motivated student to contribute towards an exciting ongoing project, performed in collaboration with Zoo Zürich, the study of an amazon milk frog (Trachycephalus resinifictrix)(fig. 1). The particularity of the frog is its distinct blue color, which is also present in the frog’s inner structure, as well as it’s impressive acrobatic capabilities (jumping). The overall aim of this project is to investigate the bone’s microstructure and blue color and link them with their mechanical properties and performance. The main method of microstructural investigation used is synchrotron scanning small-angle x-ray scattering (sSAXS), for which data of 4 frog bones (femur, tibia, humerus, radio-ulna) was collected during beamtime in 2023. Additionally. the same samples were characterized by birefringence microscopy, micro computed-tomography (μCT), nanoindentation and Raman spectroscopy to complement the data with further microstructural, morphological, mechanical and compositional data.

First results have revealed an interesting layered microstructure present in the bones, characterized by outer layers composed of transversal fibres and an inner longitudinally oriented layer (fig. 2). However, many questions are still unanswered: what is the true 3D structure? How does this structure differ from other frog bones? How does is influence the mechanical performance? what exactly is the role of the blue pigment?

If you are interested in helping answer these questions, do not hesitate to get in touch! The contents of the project will be discussed depending on the format (semester/master), the student’s interests and the current status of the project.

Requirements: some previous experience with python and jupyter notebooks is recommended, and a high level of motivation is necessary!