Understanding how metals solidify during additive manufacturing is essential for controlling their final properties. This study reveals how phase formation in 316L stainless steel is influenced by local composition when deposited onto Inconel 625 using laser-based directed energy deposition.

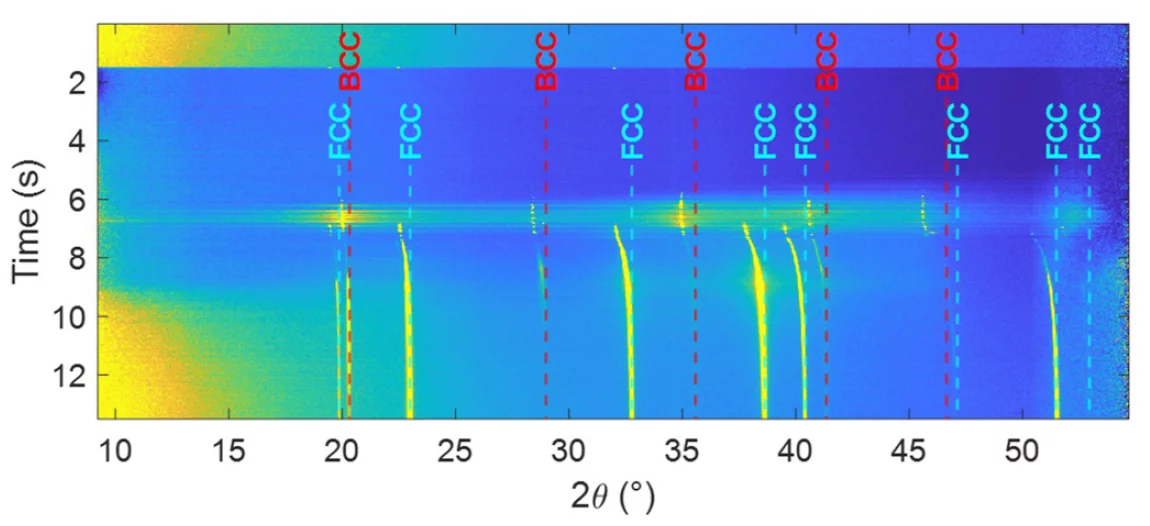

In metal 3D printing, what happens during the split-second transformation from liquid to solid defines the performance of the final part—but capturing that process as it unfolds is no small feat. In this study, researchers from ETH Zurich and the Paul Scherrer Institute (PSI) teamed up to investigate how stainless steel (316L) solidifies when deposited onto a layer of Inconel 625 using laser-based directed energy deposition (DED). Using operando synchrotron X-ray diffraction, they monitored the phase transformations in real time as the metal cooled, layer by layer, providing an unprecedented look at how local composition and solidification velocity determine whether ferrite or austenite forms first.

Their results showed that the solidification mode of 316L is not fixed, but highly sensitive to the underlying material and processing conditions. On pure 316L, a body-centered cubic (BCC) phase tends to form first, while on Inconel 625, the presence of nickel and other elements can stabilize the face-centered cubic (FCC) phase, shifting the transformation behavior entirely. These insights are critical for tailoring additive manufacturing strategies for multi-material components, where control over microstructure is key to achieving the desired mechanical and corrosion-resistant properties.

This work marks a milestone not only in additive manufacturing research, but also in the history of the Swiss Light Source. The experiment was the final one conducted at the MicroXAS beamline before the facility shut down for its major upgrade. A fitting closure, the collaboration between ETH Zurich and PSI highlights the strength of cross-institutional efforts in advancing both materials science and experimental capabilities.

Contact

Dr. Malgorzata Makowska

MicroXAS, Center for Photon Science

Paul Scherrer Institute, Forschungsstrasse 111, 5232 Villigen PSI, Switzerland

Telephone: +41 56 310 45 36, e-mail: malgorzata.makowska@psi.ch

Dr. Steven Van Petegem

Structure and Mechanics of Advanced Materials, Center for Photon Science

Paul Scherrer Institute, Forschungsstrasse 111, 5232 Villigen PSI, Switzerland

Telephone: +41 56 310 2537, e-mail: steven.vanpetegem@psi.ch

Original publication

Investigation by operando synchrotron X-ray diffraction of the phase transformation in 316L-IN625 multi-material direct energy deposition

N. Martin, T. Denoréaz, M. Bambach, S. Van Petegem, M.G. Makowska

Journal of Materials Research and Technology 36, 6821 (2025)

DOI:10.1016/j.jmrt.2025.04.278