A new machine learning–designed alloy demonstrates how materials can be tailored for specific performance properties required in additive manufacturing. Spatially resolved X-ray microdiffraction plays a crucial role in linking mechanical properties to the underlying microstructure.

Additive manufacturing (AM) – or 3D printing – enables the production of intricate metal components without the need for multiple processing steps. Unlike traditional manufacturing routes, which often include heat or deformation treatments after casting or forging, 3D-printed parts are typically used as-built. This means that their internal structure and performance are determined almost entirely by the alloy composition and the rapid heating and cooling cycles that occur during printing. The challenge, therefore, is to design alloys that are not just generally strong or ductile, but are specifically engineered to withstand the rapid solidification, thermal cycling, and cracking risks inherent to AM.

To tackle this challenge, researchers have developed a machine learning–based framework for designing new alloys tailored specifically for additive manufacturing. The approach combines thermodynamic simulations with predictive models to evaluate key material properties relevant for printing, such as solidification behavior, resistance to cracking, and how quickly strengthening particles can form. By optimising these factors, the framework identifies alloy compositions that are well suited to the unique conditions of the printing process. One such alloy was produced and printed using different laser-based techniques to validate the design.

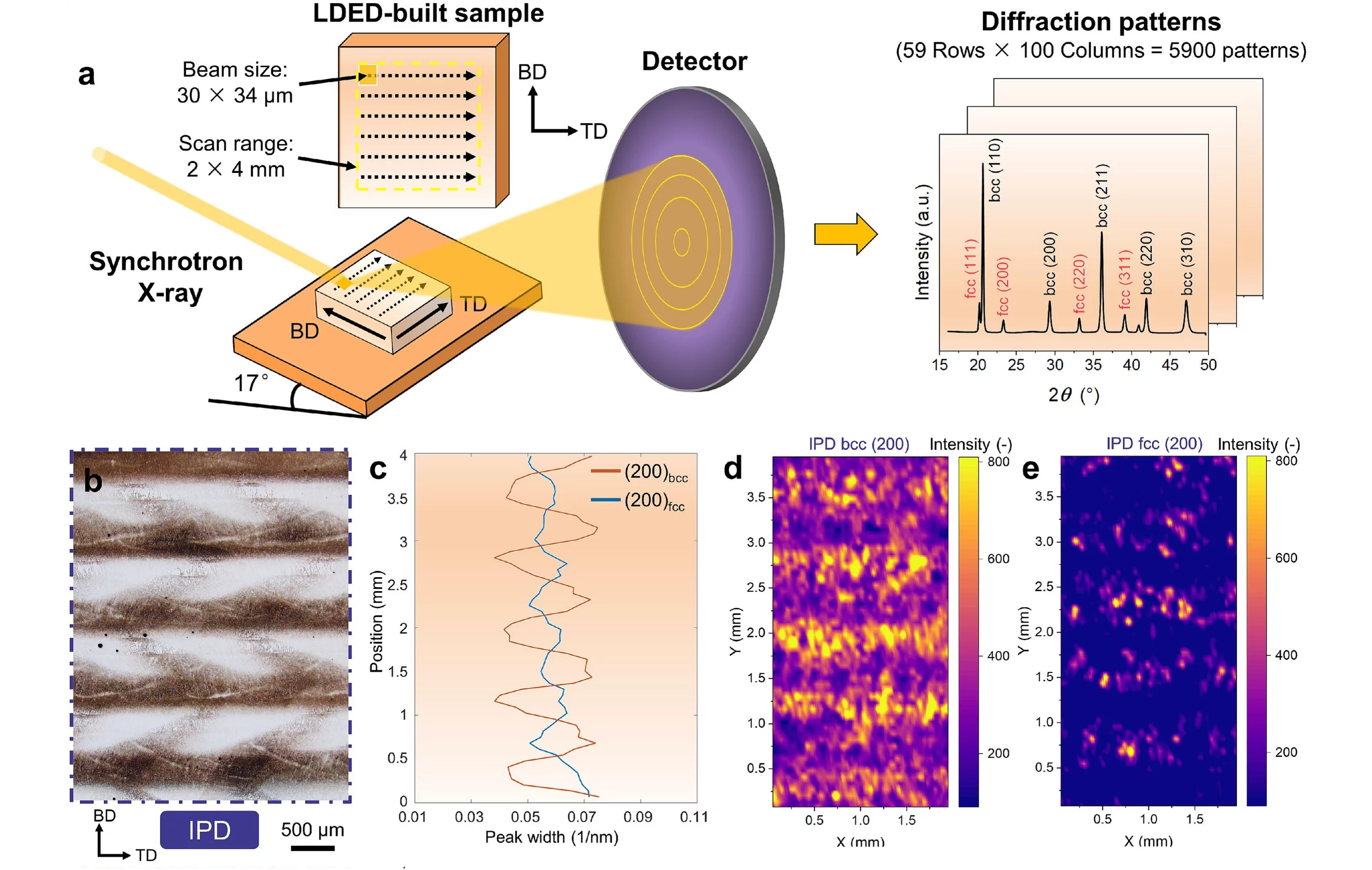

To better understand how the alloy’s internal structure evolves during printing, researchers at PSI performed high-resolution X-ray microdiffraction measurements at the MicroXAS beamline of the Swiss Light Source. Using focused synchrotron radiation, they mapped the local crystal phases and determined the dislocation density at various points within the printed material. This analysis revealed how the microstructure varied across different processing conditions and helped explain the alloy’s mechanical performance. The X-ray data provided crucial experimental validation for the design framework and offered new insights into the microscopic mechanisms that govern strength and durability in additively manufactured metals.

Contact

Dr. Steven Van Petegem

Structure and Mechanics of Advanced Materials, Center for Photon Science

Paul Scherrer Institute, Forschungsstrasse 111, 5232 Villigen PSI, Switzerland

Telephone: +41 56 310 2537, e-mail: steven.vanpetegem@psi.ch

Original publication

Additive Manufacturing Metallurgy Guided Machine Learning Design of Versatile Alloys

Jinlong Su, Lequn Chen, Steven Van Petegem, Fulin Jiang, Qinzhi Li, Junhua Luan, Swee Leong Sing, Jian Wang, Chaolin Tan

Materials Today 88, 240 (2025)

DOI: 10.1016/j.mattod.2025.06.031