Additive manufacturing, a bottom-up approach for manufacturing components layer by layer from a 3D computer model, plays a key role in the so-called “fourth” industrial revolution. Selective laser melting (SLM), one of the more mature additive manufacturing processes, uses a high power-density laser to selectively melt and fuse powders spread layer by layer. The method enables to build near full density functional parts and has viable economic benefits. Despite significant progress in recent years, the relationship between the many processing parameters and final microstructure is not well understood, which strongly limits the number of alloys that can be produced by SLM for commercial applications.

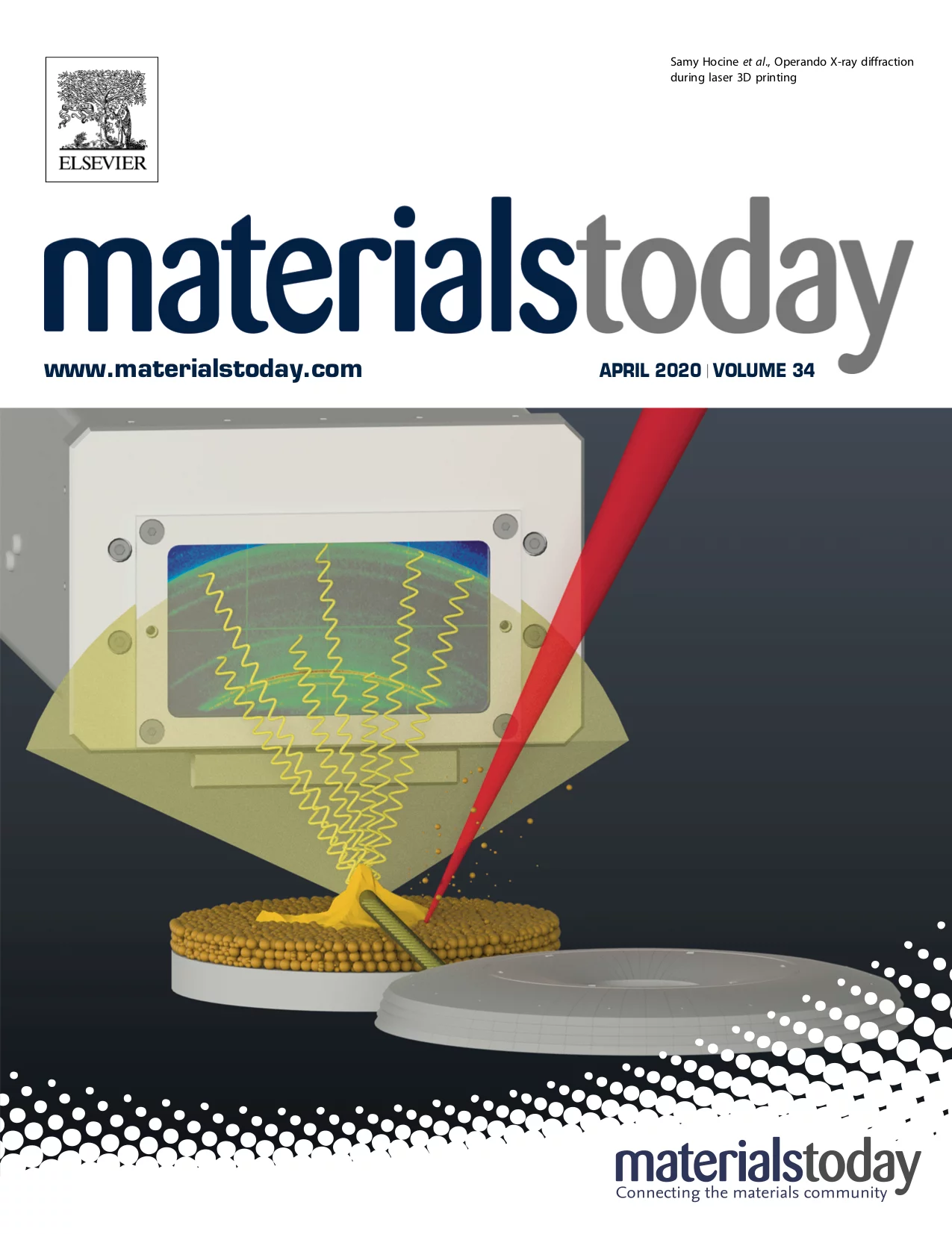

To tackle this problem, we have built a miniaturized SLM device that allows printing full 3D structures while performing ultra-fast time-resolved X-ray diffraction experiments. This new operando technique was applied during printing of Ti-6Al-4V. The experiments allowed tracking the evolution of the high temperature β-phase and the low temperature α-phase during cooling down from the melt with a temporal resolution of 0.05ms.Cooling rates up to 700’000°C/s were measured and the built-up of residual stresses could be followed. The measurements show that the length of the laser-scanning vector has a profound influence on the temperature evolution and the cooling rates experienced in the printed volume and therefore on the β -> α phase transformation, which determines the final microstructure. These new insights provide invaluable input and validation opportunities for the advanced numerical modelling techniques under development.

Contact

Helena Van Swygenhoven

Photons for Engineering and Manufacturing Group

Paul Scherrer Institut, Villigen, Switzerland

Telephone: +41 56 310 2931

E-mail: helena.vanswygenhoven@psi.ch

Original Publication

Operando X-ray diffraction during laser 3D printing

Samy Hocine, Helena Van Swygenhoven, Steven Van Petegem, Cynthia Sin Ting Chang, Tuerdi Maimaitiyili, Gemma Tinti, Dario Ferreira Sanchez, Daniel Grolimund, Nicola Casati

Materials Today 2019

DOI: 10.1016/j.mattod.2019.10.001