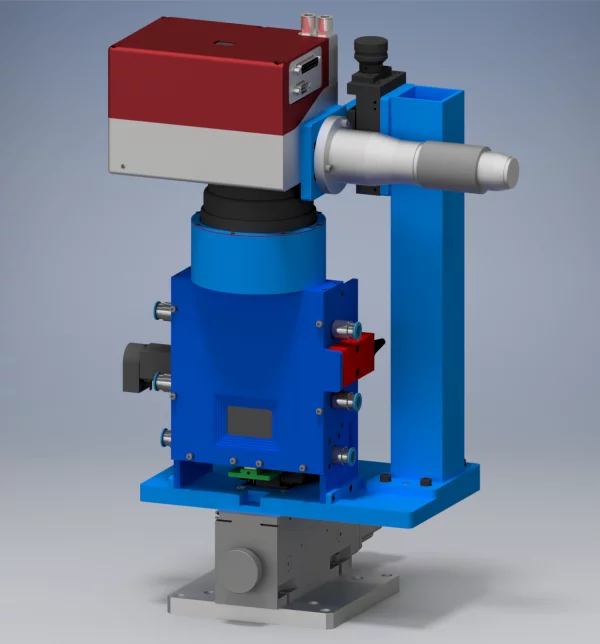

A miniaturized selective laser melting (miniSLM) device was developed to perform operando X-ray diffraction and imaging experiments at the Swiss Light Source. The device exhibits the full functionality of a commercial SLM device.

Description

A collimated infrared laser beam is deflected by a 2-axis scanning unit into the main chamber. The laser beam is focused onto a 12 × 12 mm2 build stage that can be translated vertically with a travel range of 12 mm and sub-micron step size. The build stage can be heated using a silicon-nitride resistive heater. Powder recoating is based on a hopper feeding system. The powder reservoir can be moved across the baseplate with the aid of a motor-spindle assembly. The device is completely closed, preventing laser light or particles to escape. The chamber is continuously flushed with high purity argon gas. With the aid of manual flowmeters, a slight overpressure is created in the chamber to avoid oxygen contamination by the outside atmosphere. The whole setup (laser, scanning unit and printing chamber) is cooled down with a closed-loop air-water exchange based chiller. The video below describes the basic principle behind operando X-ray diffraction during SLM.

Technical details

| Laser | ||

| Type | redPOWER® continuous wave Fiber Laser | |

| Wavelength | 1070nm | |

| Maximum power | 500W | |

| Spot size | 25 µm - 250 µm | |

| Max scanning speed | > 2000mm/s | |

| Device | ||

| Dimensions | 15mm x 20mm x 30mm | |

| Build plate | 12mm x 12mm | |

| Maximum build height | 8mm | |

| Maximum temperature | 150°C | |

| Maximum angle tilt stage | 20° |

Publications

-

Hocine S, Van Swygenhoven H, Van Petegem S

Verification of selective laser melting heat source models with operando X-ray diffraction data

Additive Manufacturing. 2021; 37: 101747 (16 pp.). https://doi.org/10.1016/j.addma.2020.101747

DORA PSI -

Hocine S, Van Petegem S, Frommherz U, Tinti G, Casati N, Grolimund D, et al.

A miniaturized selective laser melting device for operando X-ray diffraction studies

Additive Manufacturing. 2020; 34: 101194 (9 pp.). https://doi.org/10.1016/j.addma.2020.101194

DORA PSI -

Hocine S, Van Swygenhoven H, Van Petegem S, Chang CST, Maimaitiyili T, Tinti G, et al.

Operando X-ray diffraction during laser 3D printing

Materials Today. 2020; 34: 30-40. https://doi.org/10.1016/j.mattod.2019.10.001

DORA PSI