Most of the research has focussed on the study of deformation mechanisms in nanocrystalline metals. It could be shown, amoung others, that in nanocrystalline Ni with a grain size of 26nm no permanent dislocation network is built-up during plastic deformation, in contrast to what is typically observed for coarse grained fcc metals. Furthermore it has been established that multiple deformation mechanisms are operative simultaneously.

Other applications for this method are:

- the study of load transfer in nano-composites

- kinetics of the martensitic phase transformation in an fine-grained austenitic steel

- development of inter-granular strain during plastic deformation

Main publications

Deformation and degradation of superelastic NiTi under multiaxial loading

Hsu W-N, Polatidis E, Šmíd M, van Petegem S, Casati N, van Swygenhoven H

Acta Materialia. 2019; 167: 149-158.

https://doi.org/10.1016/j.actamat.2019.01.047

Revealing the role of microstructure architecture on strength and ductility of Ni microwires by in-situ synchrotron X-ray diffraction

Purushottam raj purohit R raj purohit, Arya A, Bojjawar G, Pelerin M, Van Petegem S, Proudhon H, et al.

Scientific Reports. 2019; 9(1): 79.

https://doi.org/10.1038/s41598-018-36472-3

Load path change on superelastic NiTi alloys: In situ synchrotron XRD and SEM DIC

Hsu W-N, Polatidis E, Šmíd M, Casati N, Van Petegem S, Van Swygenhoven H

Acta Materialia. 2018; 144: 874-883.

https://doi.org/10.1016/j.actamat.2017.11.035

An in-situ synchrotron study on microplastic flow of electrodeposited nanocrystalline nickel

Ghosh P, Van Petegem S, Van Swygenhoven H, Chokshi AH

Materials Science and Engineering A: Structural Materials: Properties, Microstructure and Processing. 2017; 701: 101-110.

https://doi.org/10.1016/j.msea.2017.06.075

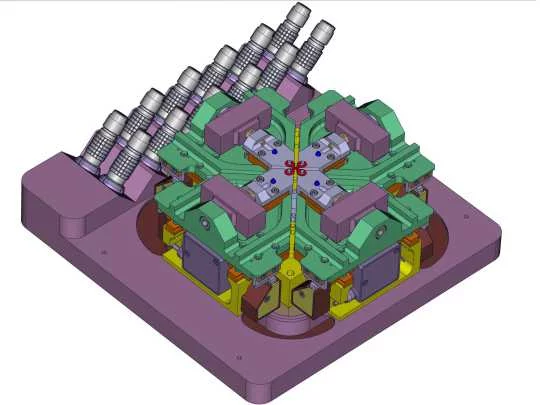

A Miniaturized Biaxial Deformation Rig for in Situ Mechanical Testing

Van Petegem S, Guitton A, Dupraz M, Bollhalder A, Sofinowski K, Upadhyay M V, Van Swygenhoven H

Experimental Mechanics 57, 569-580 (2017).

DOI: 10.1007/s11340-016-0244-0

Deformation behavior of nano-porous polycrystalline silver. Part II: Simulations

Zabihzadeh S, Cugnoni J, Duarte L I, Van Petegem S, Van Swygenhoven H

Acta Materialia 131, 564-573 (2017).

DOI: 10.1016/j.actamat.2017.04.041

Deformation behavior of nanoporous polycrystalline silver. Part I: Microstructure and mechanical properties

Zabihzadeh S, Van Petegem S, Holler M, Diaz A, Duarte LI, Van Swygenhoven H

Acta Materialia 131, 467 (2017).

DOI: 10.1016/j.actamat.2017.04.021

Grain size and alloying effects on dynamic recovery in nanocrystalline metals

Sun Z, Van Petegem S, Cervellino A, Blum W, Van Swygenhoven H

Acta Materialia 119, 104-114 (2016).

DOI: 10.1016/j.actamat.2016.08.019

Deformation behavior of sintered nanocrystalline silver layers

Zabihzadeh S, Van Petegem S, Duarte L I, Mokso R, Cervellino A, Van Swygenhoven H

Acta Materialia 97, 116-123 (2015).

DOI: 10.1016/j.actamat.2015.06.040

Dynamic recovery in nanocrystalline Ni

Z. Sun, S. Van Petegem, A. Cervellino et al.

Acta Materialia 91, 91 (2015).

On the origin of cementite diffraction peak broadening during tensile deformation at ambient temperatures

M.A. Weisser, S. Van Petegem, A. Cervellino et al.

International Journal of Plasticity 66, 138 (2015).

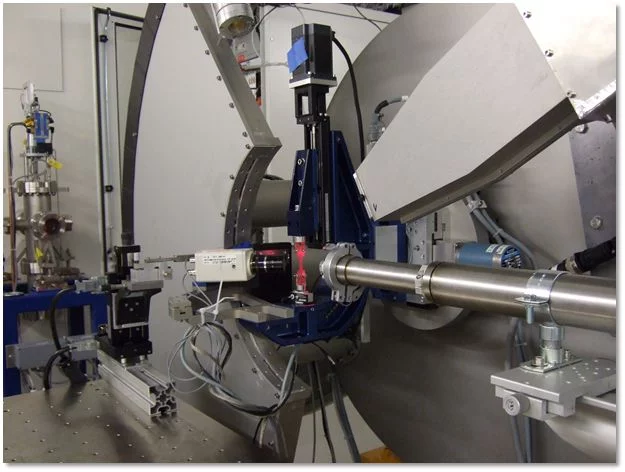

In-situ mechanical testing during X-ray diffraction

Helena Van Swygenhoven, Steven Van Petegem

Materials Characterization 78, 47 (2013).

Slip-induced intergranular stress redistribution in nanocrystalline Ni

L Li, S Van Petegem, H Van Swygenhoven, PM Anderson

Acta Materialia 60, 7001 (2012).

Two strain-hardening mechanisms in nanocrystalline austenitic steel: An in situ synchrotron X-ray diffraction study

P Schloth, MA Weisser, H Van Swygenhoven, S Van Petegem, P Susila, VS Sarma, BS Murty, S Lauterbach, M Heilmaier

Scripta Materialia 66, 690 (2012).

Yield point phenomenon during strain rate change in nanocrystalline Ni-Fe

S Van Petegem, J Zimmermann, H Van Swygenhoven

Scripta Materialia 65, 217 (2011).

In situ room temperature tensile deformation of a 1% CrMoV bainitic steel using synchrotron and neutron diffraction

MA Weisser, AD Evans, S Van Petegem, SR Holdsworth, H Van Swygenhoven

Acta Materialia 59, 4448 (2011).

On the microstructure of nanoporous gold: an x-ray diffraction study

S. Van Petegem, S. Brandstetter, R. Maaß, A.M. Hodge, B.S. El-Dasher, J. Biener, B. Schmitt, C. Borca, H. Van Swygenhoven

Nanoletters 9, 1158 (2009)

Creep in nanocrystalline Ni during x-ray diffraction

S. Van Petegem, S. Brandstetter, B. Schmitt, R. Maass, H. Van Swygenhoven

Scripta Materialia 60, 29 (2009)

A new criterion for elasto-plastic transition in nanomaterials: Application to size and composite effects on Cu-Nb nanocomposite wires

L. Thilly, S. Van Petegem, P.-O. Renault, F. Lecouturier, V. Vidal, B. Schmitt, H. Van Swygenhoven

Acta Materialia 57, 3157 (2009)

Evidence of internal Bauschinger test in nanocomposite wires during in situ macroscopic tensile cycling under synchrotron beam

L. Thilly, S. Van Petegem, P.O. Renault, V. Vidal, F. Lecouturier, S. Brandstetter, B. Schmitt, H. Van Swygenhoven

Applied Physics Letters 90, 241907 (2007)

From Micro- to Macroplasticity

S. Brandstetter, H. Van Swygenhoven,S. Van Petegem, B. Schmitt, R. Maass, P.M. Derlet

Advanced Materials 18, 1545 (2006)

Following peak profiles during elastic and plastic deformation: A synchrotron-based technique

H. Van Swygenhoven, B. Schmitt, P. M. Derlet, S. Van Petegem, A. Cervellino, Z. Budrovic, S. Brandstetter, A. Bollhalder, and M. Schild

Review of Scientific Instruments 77, 013902 (2006)

Footprints of deformation mechanisms during in-situ X-ray diffraction: nanocrystalline and ultra-fine grained Ni

Z. Budrovic, S. Van Petegem, P.M. Derlet, B. Schmitt, H. Van Swygenhoven, E. Schafler, M. Zehetbauer

Applied Physics Letters 86, 231910 (2005)

Temperature-dependent residual broadening of x-ray diffraction spectra in nanocrystalline plasticity

S. Brandstetter, Z. Budrovic, S. Van Petegem, B. Schmitt, E. Stergar, P. M. Derlet, and H. Van Swygenhoven

Applied Physics Letters 87, 231910 (2005)

Plastic deformation with reversible peak broadening in nanocrystalline Ni.

Z. Budrovic, H.Van Swygenhoven, P.M.Derlet, S. Van Petegem, Bernd Schmitt.

Science 304, 273 (2004)