The fabrication of engineering materials often involves a number of thermo-mechanical treatments during which the material is heated up to high temperature, followed by a cooling process. Depending on the cooling rate very different microstructures can be generated. In fact, controlling the cooling rate of an alloy during solidification is the most commonly used method for varying the microstructure in traditional manufacturing processes. Furthermore, in certain advanced manufacturing processes, such as laser based additive manufacturing techniques, very high cooling rates up to a few ten thousand K/s can be reached, resulting in microstructures that would not arise during conventional processes. In situ synchrotron x-ray diffraction and small angle scattering are ideal techniques to investigate the kinetics of the microstructure evolution during fast cooling, provinding input for models that aim to predict the behaviour of engineering materials under such conditions. In order to achieve high cooling rates, a laser based heating system is employed. Details on the laser can be found in J. Synchrotron Radiat. 19, 352 (2012). DOI: 10.1107/S0909049512003287.

In Situ X-ray Diffraction

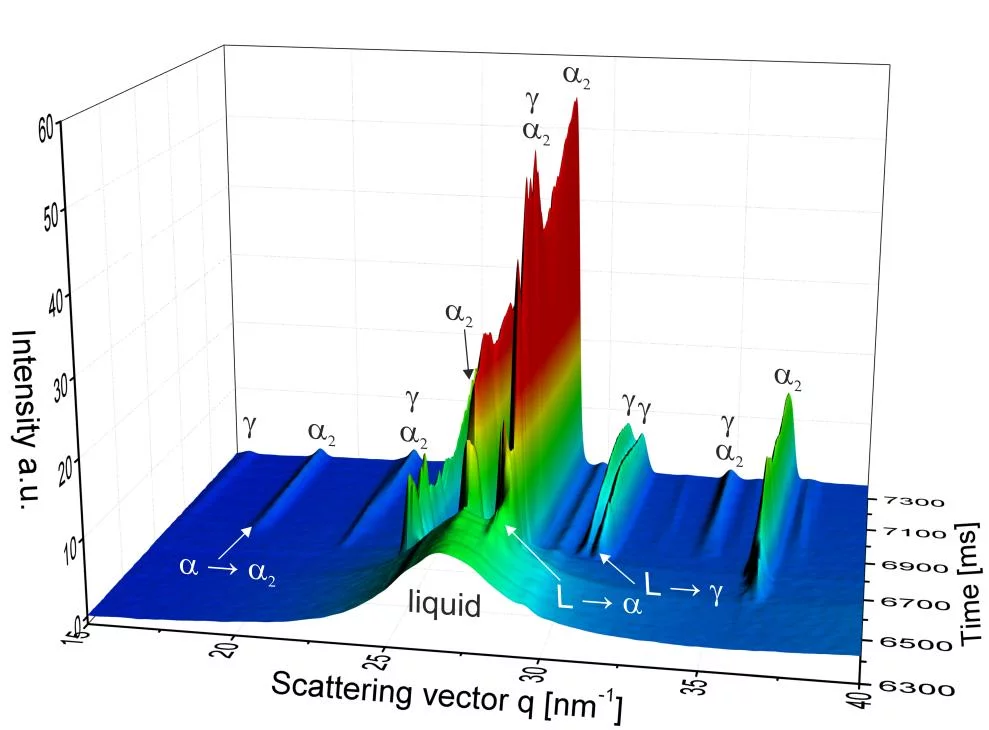

In situ x-ray diffraction allows tracking the phase evolution during heating and fast cooling processes. For that the laser based heating system is installed at the MicroXAS beamline of the Swiss Light Source. Small spheres (~1mm) are placed on a Cu and melted with the aid of a high power laser beam. By removing the laser power the sphere quickly cool down with a cooling rate >1000 K/s. Simultaneously the top part of the sphere is illuminated by a focused x-ray beam. The diffracted beam is recorded with a 2D EIGER 4M detector with a frame rate up to 400Hz.

In situ Small Angle X-ray Scattering

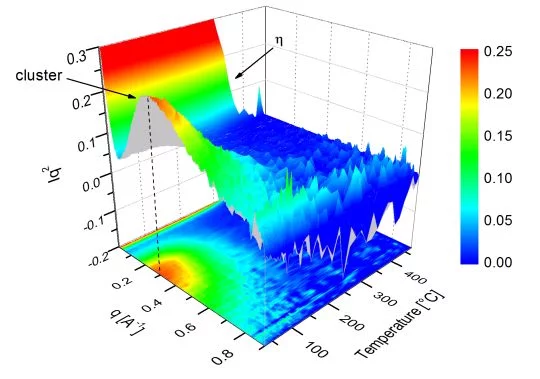

Small angle x-ray scattering (SAXS) is sensitive to changes in electron density on a length scale ranging from one to a few hundreds of nanometers, which provides information on size, shape, density and volume fraction of the scattering objects. It is therefore an ideal tool to investigate the formation of precipitates during cooling. This was demonstrated for an aluminum alloy at the cSAXS beam line of the Swiss Light Source. The sample is heated with the laser furnace to the solutionizing temperature of 474°C and cooled down to room temperature with various cooling rates (~10-30 K/s). The SAXS pattern reveal the sequential formation of the eta phase and guinier-preston zones.

Main publications

Combined in situ synchrotron micro X-ray diffraction and high-speed imaging on rapidly heated and solidified Ti-48Al under additive manufacturing conditions

Kenel C, Grolimund D, Fife JL, Samson VA, Van Petegem S, Van Swygenhoven H, Leinenbach C

Scripta Materialia 114, 117 (2016).

DOI: 10.1016/j.scriptamat.2015.12.009

In Situ Synchrotron X-Ray Diffraction and Small Angle X-Ray Scattering Studies on Rapidly Heated and Cooled Ti-Al and Al-Cu-Mg Alloys Using Laser-Based Heating

Kenel C, Schloth P, Van Petegem S, Fife JL, Grolimund D, Menzel A, Van Swygenhoven H, Leinenbach C

JOM *683, 978 (2016).

DOI: 10.1007/s11837-015-1774-0

Early cluster formation during rapid cooling of an Al-Cu-Mg alloy: In situ small-angle X-ray scattering

Schloth P, Menzel A, Fife J L, Wagner J N, Van Swygenhoven H, Drezet J -M

Scripta Materialia 108, 56-59 (2015).

DOI: 10.1016/j.scriptamat.2015.06.015

Early precipitation during cooling of an Al-Zn-Mg-Cu alloy revealed by in situ small angle X-ray scattering

Schloth P, Wagner J N, Fife J L, Menzel A, Drezet J -M, Van Swygenhoven H

Applied Physics Letters 105, 101908 (2014).

DOI: 10.1063/1.4894768

Kenel C, Grolimund D, Fife JL, Samson VA, Van Petegem S, Van Swygenhoven H, Leinenbach C

Scripta Materialia 114, 117 (2016).

DOI: 10.1016/j.scriptamat.2015.12.009

In Situ Synchrotron X-Ray Diffraction and Small Angle X-Ray Scattering Studies on Rapidly Heated and Cooled Ti-Al and Al-Cu-Mg Alloys Using Laser-Based Heating

Kenel C, Schloth P, Van Petegem S, Fife JL, Grolimund D, Menzel A, Van Swygenhoven H, Leinenbach C

JOM *683, 978 (2016).

DOI: 10.1007/s11837-015-1774-0

Early cluster formation during rapid cooling of an Al-Cu-Mg alloy: In situ small-angle X-ray scattering

Schloth P, Menzel A, Fife J L, Wagner J N, Van Swygenhoven H, Drezet J -M

Scripta Materialia 108, 56-59 (2015).

DOI: 10.1016/j.scriptamat.2015.06.015

Early precipitation during cooling of an Al-Zn-Mg-Cu alloy revealed by in situ small angle X-ray scattering

Schloth P, Wagner J N, Fife J L, Menzel A, Drezet J -M, Van Swygenhoven H

Applied Physics Letters 105, 101908 (2014).

DOI: 10.1063/1.4894768