The PROBAB (2016 – 2018) project is supported by the Swiss Nuclear Safety Inspectorate (ENSI) and is dealing with deterministic and probabilistic structural integrity and lifetime assessments of pressure boundary components in the primary coolant circuit of LWRs in the context of material ageing and the safe long-term operation of Swiss nuclear power plants. Special emphasis is currently placed to the reactor pressure vessel (RPV), which cannot be exchanged and is the most critical component with regard to safe operation and service lifetime. The continuous irradiation of the RPV in the core region by high energy neutrons results in a reduction of the toughness and ductility of the RPV steels (= irradiation embrittlement).

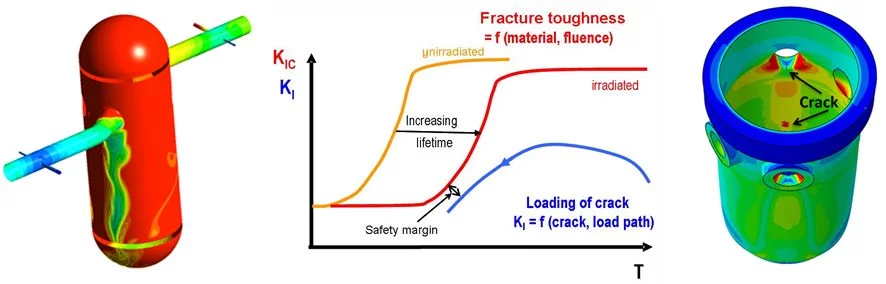

One major goal of the current PROBAB project is to establish the probabilistic approaches in Switzerland as a complement to the existing deterministic methods and to built-up a corresponding excellence and expertise at PSI. For that purpose, the advantages, limitations and shortcomings of probabilistic fracture mechanics methods are critically evaluated by important specific reference examples: The RPV integrity in the context of irradiation embrittlement is studied for a model PWR RPV that is subjected to pressurized thermal shock (PTS) loads. Such severe loads may occur in case of loss of coolant accidents (LOCA), when the emergency core cooling system (ECCS) injects cold water into the hot RPV in order to ensure the cooling of the reactor core. This shock-like cooling in combination with the remaining pressure cause high stresses in the RPV wall that could result in a brittle failure in case of pre-existing cracks.

In the PROBAB project, these probabilistic methods are now also increasingly extended to active degradation and ageing mechanisms like stress corrosion cracking or thermo-mechanical fatigue in RPV internal attachment welds, nozzles and piping that may result in the formation and subcritical growth of cracks, and finally, if not detected, in a large leak or component failure and thus subsequent LOCA scenarios. Such cracks thus have to be detected by the periodic in-service inspection (ISI) before they reach a critical size for safety. For these situations, probabilistic leak-before-break (LBB) evaluations are performed to assess the occurrence frequencies of leaks of different size and to verify the current ISI inspection intervals. Such evaluations shall demonstrate that a pipe rupture is an extremely low probable event and that such growing cracks usually first result in a small, detectable leak before a complete rupture of the component occurs, and thus adequate countermeasures (repair, exchange etc.) can be applied in due time.