- Zirconium alloys are used as cladding, acting as the first barrier for the nuclear fuel, in the present light water reactors (LWR).

- Different alloys of Zr are optimized to show a high resistance to oxidation and hydrogen uptake in the reactor.

- However, the severe reactor environment and the irradiation gradually cause structural degradations and will lead to a limited lifetime of the cladding. One of the consequences of the degradation due to irradiation is the change of oxidation and hydrogen uptake properties of the cladding after several service years.

- PSI has long term experience in the field of determination of the role of irradiation on the service time (no. of cycles), as well as in the fundamental research in the field of oxidation in Zr based alloys.

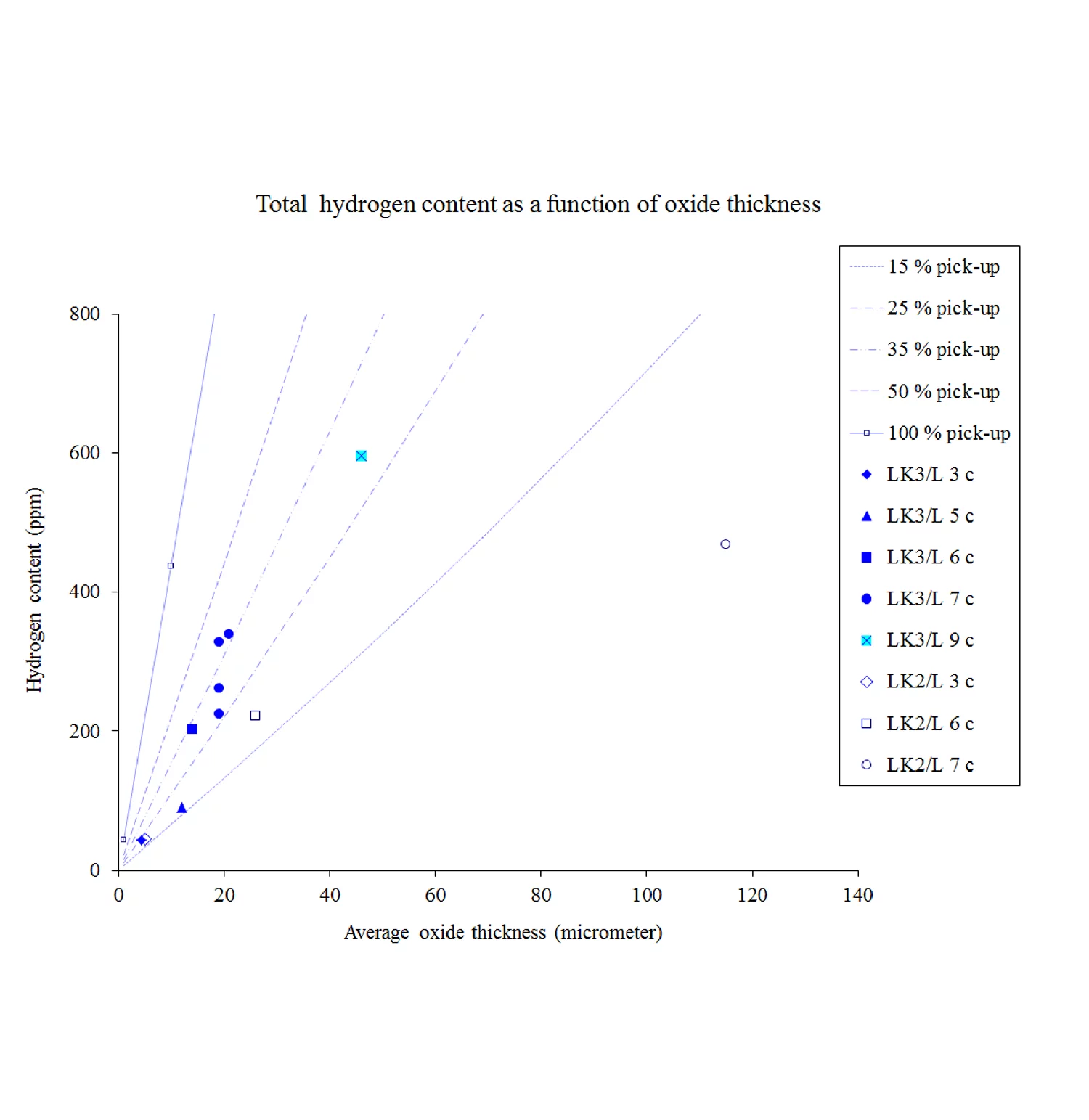

- In the Hydrogen Uptake project, the focus is on the correlation of the service life to the oxidation extent and hydrogen uptake.

- The phenomenon of hydrogen uptake seems to depend on the type of alloy, and PSI has revealed that an alloy with low oxidation rate will not necessarily have lower hydrogen uptake or hydrogen pickup fraction.

Methods used to examine oxidation and Hydrogen uptake

- The studies start by a pool side examination (non-destructive tests, NDT)

- Subsequently the selected rods are transferred to the hot laboratory and extended NDT is performed in the hot-cells

- Following that step the destructive experiments are planned

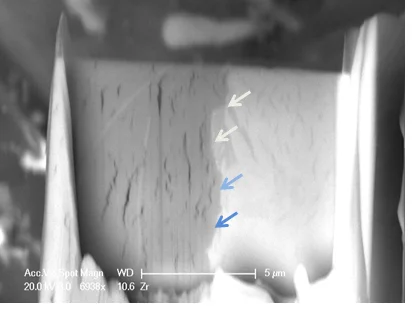

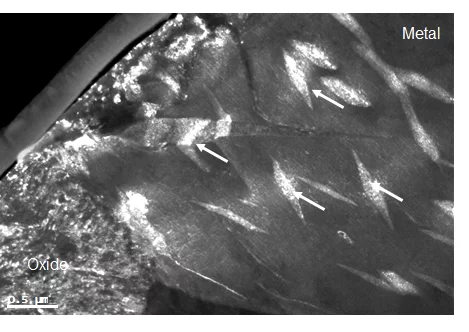

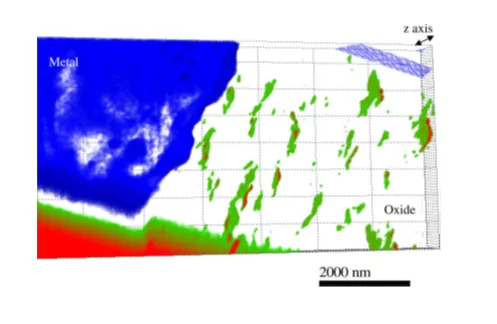

- Optical microscopy (OM), electron probe microanalysis (EPMA), secondary ion mass spectroscopy (SIMS), are performed on selected samples. These studies precede the observations by more advanced techniques such as 3D-FIB, transmission electron microscopy (TEM) and analytical TEM and Synchrotron studies.

- Chemical studies include ICP-MS and hot gas extraction

- The examinations are supported at a certain stage by modelling.

- Furthermore, using correlative microscopy the similar regions are studied by different techniques and are compared for better characterization of the material