Nickel–copper alloys are attractive for 3D printing thanks to their tunable properties, but they often suffer from unexpected cracking. Our research uncovers how phase separation drives this failure and what it means for designing more reliable multi-material systems

Additive Manufacturing: New Possibilities, New Challenges

Additive manufacturing (AM), commonly known as 3D printing, has transformed the way we design and produce complex components. By building parts layer by layer, AM enables geometries and material combinations that would be impossible to achieve using traditional manufacturing. From lightweight aerospace components to custom biomedical implants, the technology is pushing the boundaries of what is possible in engineering and materials science.

Why Ni–Cu Alloys?

Among the many material systems being explored, nickel–copper (Ni–Cu) alloys stand out for their excellent corrosion resistance, mechanical stability, and the potential to tailor properties by adjusting composition. This makes them especially interesting for multi-material AM applications, where different alloys can be combined within a single build. However, despite their promise, Ni–Cu systems have shown a stubborn tendency to develop cracks during the printing process — a problem that undermines their reliability and limits their industrial adoption.

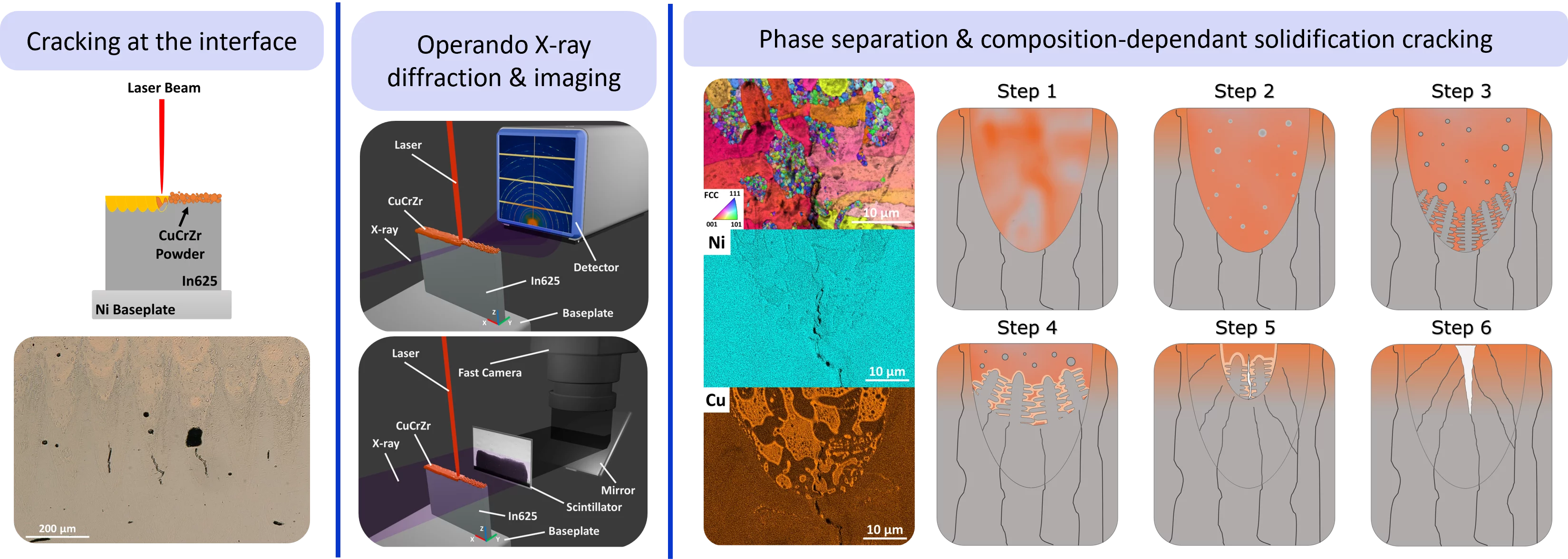

Cracks from Liquid Phase Separation

Our study shows that the cracking originates from liquid-phase immiscibility in the melt when CuCrZr is fused with IN625. During laser powder-bed fusion, the pool splits into a Cu-rich liquid (LCu) and a Ni-rich liquid (LNi) because Cu interacts unfavorably with IN625’s alloying elements (notably Cr, Fe, and Mo). As the build cools, the Ni-rich solid forms while Cu-rich liquid persists along grain boundaries, creating a wide mushy zone in which cracks open late in solidification. Operando X-ray diffraction and high-speed radiography captured this terminal-stage crack initiation near melt-pool centerlines, where columnar Ni-rich grains are separated by lingering Cu-rich films.

Towards More Reliable Multi-Material Printing

Thermodynamic calculations and experiments converge on a crack-susceptible composition window of ~20–40 wt.% CuCrZr-IN625. We validated this by printing blends across the range and quantifying crack density. The exact peak shifts with heat input and cooling rate (e.g., ~30 wt.% at higher energy, ~40 wt.% at lower energy), consistent with undercooling effects. In contrast, CuCrZr mixed with pure Ni showed no phase separation and no cracks, underscoring the role of IN625’s alloying elements in driving immiscibility.

Practically, this means you can reduce risk by avoiding the 20–40 wt.% mixing zone at Cu/Ni interfaces, tuning melt-pool shape and energy input to limit mixing, and—where possible—selecting combinations that do not promote immiscibility. Because the same enthalpy-of-mixing logic applies to other Ni–Cu systems containing elements like Cr, Fe, Mo, V, W, the mechanism and mitigation principles extend well beyond the specific CuCrZr-IN625 pair.

By identifying the true cause of cracking, this work offers a framework for designing more robust multi-material systems.

Contact

Dr. Steven Van Petegem

Structure and Mechanics of Advanced Materials, Center for Photon Science

Paul Scherrer Institute, Forschungsstrasse 111, 5232 Villigen PSI, Switzerland

Telephone: +41 56 310 2537, e-mail: steven.vanpetegem@psi.ch

Original publication

Phase-Separation-Driven Cracking in Additive Manufacturing of Ni-Cu Alloy Systems

Andaç Özsoy, Steve Gaudez, William A. Hearn, Antonios Baganis, Zoltán Hegedüs, Yunhui Chen, Alexander Rack, Roland E. Logé, Steven Van Petegem

Additive Manufacturing 110, 104950 (2025)

DOI: 10.1016/j.addma.2025.104950