The internal phase structure of 3D-printed steels controls performance, but key features are buried deep inside the material and are hard to detect. Through 3D synchrotron X-ray mapping and operando diffraction, this work reveals hidden retained-austenite networks and links them directly to printing conditions.

Additive manufacturing is attracting strong interest for the development of structural materials for future fusion reactors. Fusion environments require materials that can withstand extreme heat loads, steep temperature gradients, high radiation damage and demanding mechanical conditions. Conventional processing routes make it difficult to engineer complex geometries, integrate cooling channels, or tailor microstructures locally where they are most needed. Laser-based additive manufacturing offers new opportunities because it enables the production of highly complex components, allows fine control over local processing, and provides flexibility for designing materials directly for function and performance. However, these benefits come with new scientific challenges.

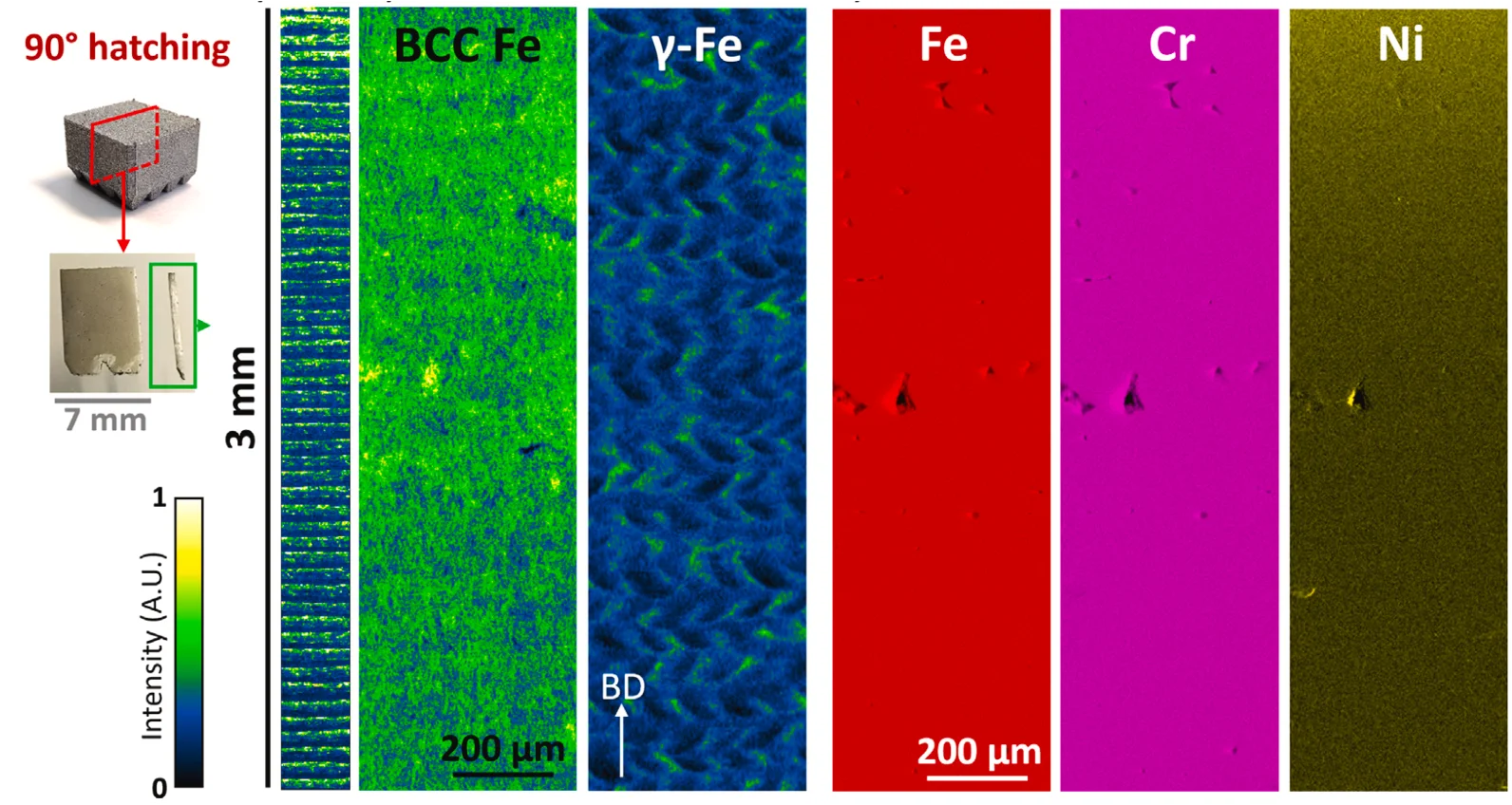

During laser 3D printing, metals experience very rapid and repeated heating and cooling cycles. These complex thermal histories create intricate internal structures that strongly influence material strength, stability and lifetime, especially in harsh environments such as fusion reactors. Many of these features remain hidden deep inside the material and cannot be detected using conventional microscopy or standard X-ray diffraction techniques. In particular, it has been unclear how and where small regions of austenite form inside steels that are expected to transform largely into ferritic–martensitic phases. Without direct three-dimensional insight, it is difficult to fully understand how printing parameters control the final material state.

In this work, advanced 3D synchrotron X-ray mapping was combined with operando diffraction measurements to directly “look inside” laser-printed ferritic–martensitic steels. These techniques made it possible to reconstruct the internal phase distribution in three dimensions and to follow how phases evolve during heating. The study revealed previously unseen networks of retained austenite that form depending on the laser scanning strategy. This clearly shows that the chosen printing path leaves a permanent imprint in the material, creating hidden phase networks that strongly influence microstructure and properties, but cannot be detected with conventional analysis.

This research is the result of a strong collaboration across three PSI Centers: the Center for Nuclear Engineering and Sciences, the Center of Photon Science, and the Center for Neutron and Muon Sciences. This collaborative effort provides new understanding of how additive manufacturing shapes the microstructure of fusion-relevant steels and supports the development of reliable, knowledge-based strategies for future fusion energy technologies.

Contact

Dr. Malgorzata Makowska

Advanced Nuclear Materials Group, Center for Nuclear Engineering and Sciences

Paul Scherrer Institute, Forschungsstrasse 111, 5232 Villigen, Switzerland

Telephone: +41 56 310 45 36, e-mail: malgorzata.makowska@psi.ch

Dr. Steven Van Petegem

Structure and Mechanics of Advanced Materials, Center for Photon Science

Paul Scherrer Institute, Forschungsstrasse 111, 5232 Villigen PSI, Switzerland

Telephone: +41 56 310 2537, e-mail: steven.vanpetegem@psi.ch

Original publication

Additive Manufacturing and Advanced Microstructural Characterization of a Ferritic-Martensitic Stainless Steel

Natan Garrivier, Steven Van Petegem, Markus Strobl, Manuel Pouchon, Enrico Tosoratti, Adam Cretton, Ken Vidar Falch, Dario Ferreira Sanchez, and Malgorzata Makowska

Additive Manufacturing 115, 105055 (2026)

DOI: 10.1016/j.addma.2025.105055