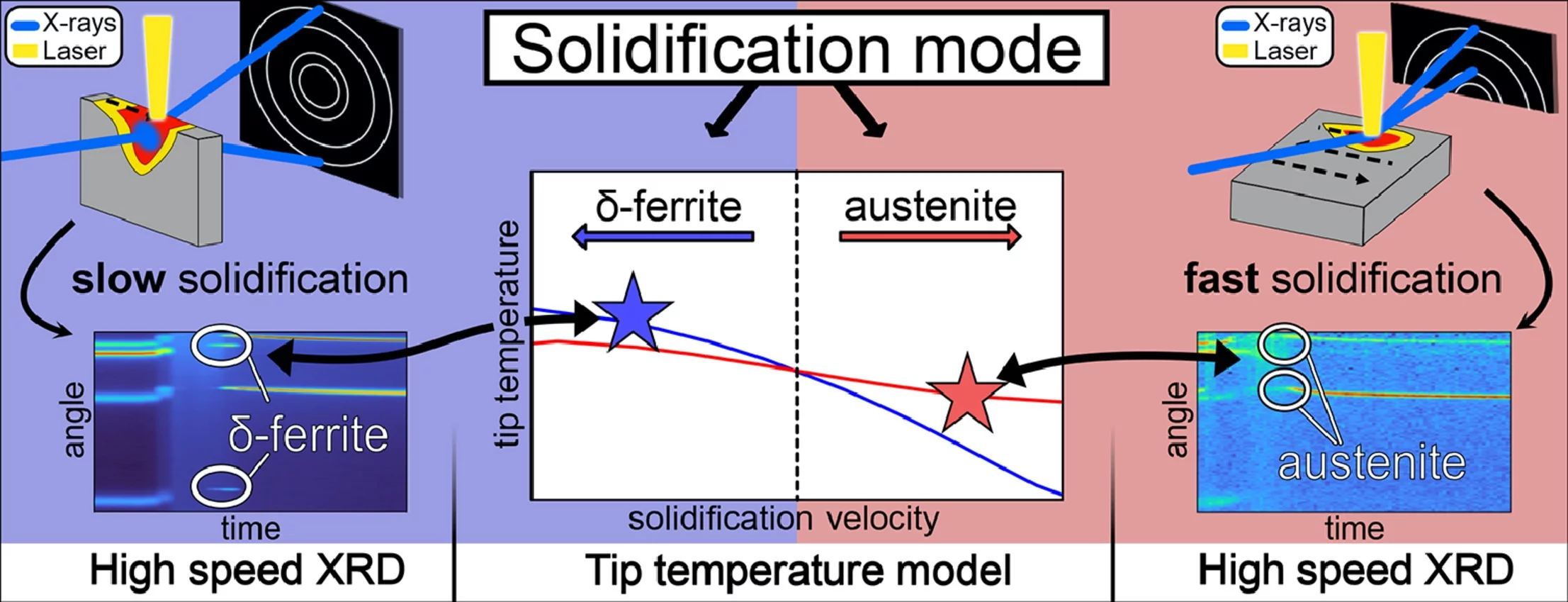

Solidification during fusion-based additive manufacturing is characterized by high solidification velocities and large thermal gradients, two factors that control the solidification mode of metals and alloys. Using two synchrotron-based, in situ setups, we perform high-speed X-ray diffraction measurements to investigate the impact of the solidification velocities and thermal gradients on the solidification mode of a hot-work tool steel over a wide range of thermal conditions.

Additive manufacturing (AM) of metals, or metal 3D printing, has attracted increasing attention due to the geometrical design freedom, allowing for new, previously unimaginable applications of metallic materials. The most common metal AM technology is based on melting and subsequent solidification of metal powder layers using a laser energy source, i.e., laser powder bed fusion (L-PBF), where metallic components are created layer-by-layer from the powder feedstock. The high laser scanning speeds create comparable small melt pools that solidify rapidly resulting in solidification structures governed by highly transient solidification conditions. For conventional metallurgical processes, solidification can often be described by assuming local equilibrium at the solidification front (the phase boundary) between the liquid and solid phases. However, at the high solidification velocities typical for the AM processes, deviation from such a local-equilibrium assumption is expected.

In the present study, we utilize two different in situ L-PBF sample environments implemented at MicroXAS of the Swiss Light Source and at 1-ID-E of the Advanced Photon Source to understand the solidification modes of a hot-work tool steel under two processing conditions. The goal is to elucidate the solidification mode, focusing on the change of the solidification mode from primary δ-ferrite to primary γ with increasing solidification velocity.

The solidification mode of primary δ-ferrite is observed at a cooling rate of 2.12 × 104 K/s, whereas at a higher cooling rate of 1.5 × 106 K/s, δ-ferrite is suppressed, and primary austenite is observed. The experimental thermal conditions are evaluated and linked to a Kurz-Giovanola-Trivedi (KGT) based solidification model. The modelling results show that the predictions from the multicomponent KGT model agree with the experimental observations. This work highlights the role of in situ XRD measurements for a fundamental understanding of the microstructure evolution during AM and for validation of computational thermodynamics and kinetics models, facilitating parameter and alloy development for AM processes.

Contact

Dr. Steven Van Petegem

Structure and Mechanics of Advanced Materials

Photon Science Division

Paul Scherrer Institute

Forschungsstrasse 111, 5232 Villigen PSI, Switzerland

Telephone: +41 56 310 2537

E-mail: steven.vanpetegem@psi.ch

Original publication

Hans-Henrik König, Niklas Holländer Pettersson, A. Durga, Steven Van Petegem, Daniel Grolimund, Andrew Chihpin Chuang, Qilin Guo, Lianyi Chen, Christos Oikonomou, Fan Zhang, Greta Lindwall

Acta Materialia 246 (2023) 118713

DOI: 10.1016/j.actamat.2023.118713