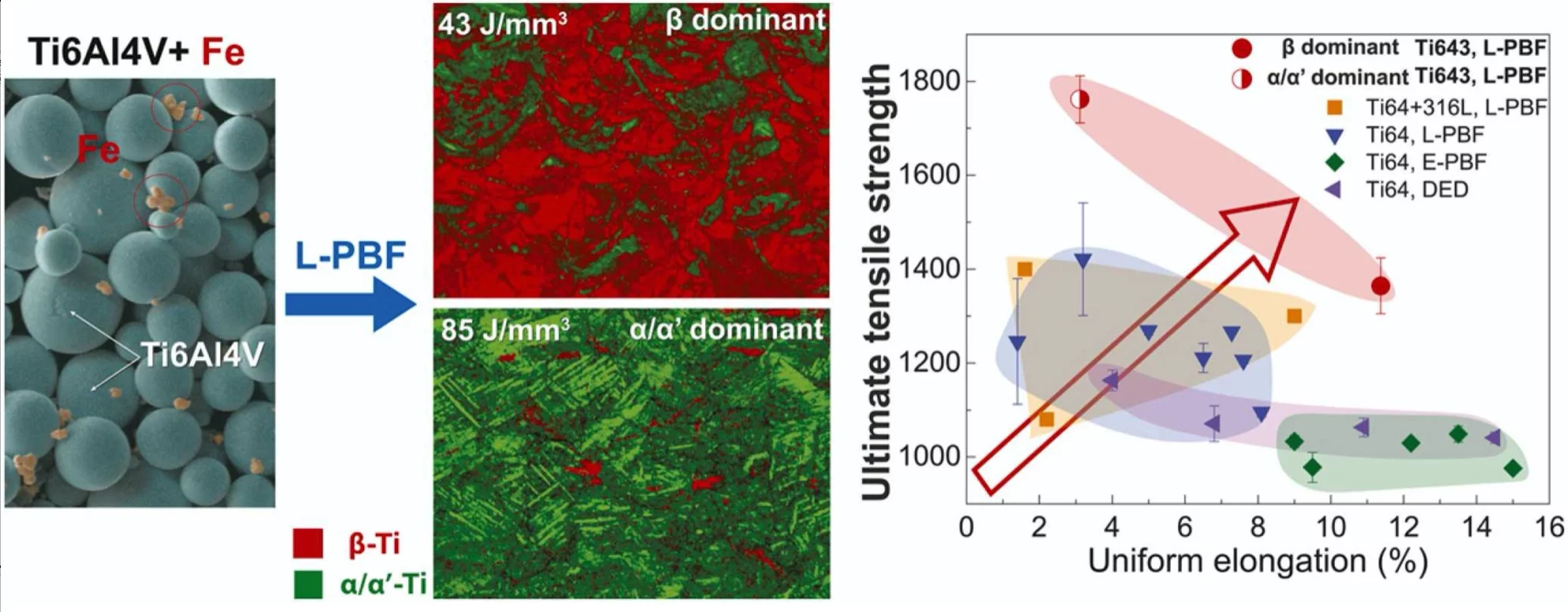

High-speed operando X-ray diffraction during additive manufacturing combined with X-ray fluorescence and electron backscatter diffraction allows for relating the microstructure with the process parameters during in situ alloying of Ti6Al4V with Fe. It is demonstrated that the mechanical properties can be optimised for either high strength or enhanced ductility without post-processing heat treatments.

Additive Manufacturing of metallic powders to build near-net-shaped components with complex structures has advanced in the last decade rapidly. Titanium (Ti) alloys, in particular Ti-6Al-4V (Ti64), with outstanding weldability, fabricated by Laser Powder Bed Fusion (L-PBF), have drawn enormous attention due to the high strength-to-weight ratio and excellent corrosion resistance for applications in aerospace and bio-medical sectors. However, Ti64 fabricated by L-PBF suffers from the formation of hierarchical structures of acicular martensitic α’ grains within large columnar prior β-grains. This anisotropic microstructure with brittle martensitic phase results in inferior ductility, fatigue resistance and fracture toughness. Recently, it was shown that the addition of Fe has great potential to fabricate metastable β-Ti alloys with refined β grains, resulting in superior mechanical properties.

Using blended powders as opposed to a pre-alloyed feedstock offers considerable freedom to design novel alloys and sufficient flexibility to adjust their composition. Most reports in the literature focus on the chemical composition of the powder mixtures and their effect on the phase fractions. But the elemental distribution also plays an important role on microstructures and associated mechanical properties.

In a collaborative effort between researchers from the Paul Scherrer Institute, the University of Notthingham and the Loughborough University, the role of the L-PBF laser process parameters on the resulting microstructures and mechanical properties of a blended powder that consists of Ti64 with 3 wt% Fe particles was studied. With increasing volume energy densities, the as-built microstructures transit from β dominant to nearly complete martensitic α’ microstructures. Superior mechanical properties are achieved in the β-dominant Ti-alloy. This study demonstrates an effective way to engineer specific microstructures and paves the way to create functionally gradient properties in additively manufactured Ti alloys by simply controlling laser manufacturing parameters.

Part of the research was performed at the MicroXAS beamline at the Swiss Light Source using a miniaturized laser powder bed fusion device.

Contact

Dr. Steven Van Petegem

Structure and Mechanics of Advanced Materials

Photon Science Division

Paul Scherrer Institute

Forschungsstrasse 111, 5232 Villigen PSI, Switzerland

Telephone: +41 56 310 2537

E-mail: steven.vanpetegem@psi.ch

Original publication

Microstructural engineering of a dual-phase Ti-Al-V-Fe alloy via in situ alloying during laser powder bed fusion

Ming Chen, Steven Van Petegem*, Zhiyi Zou, Marco Simonelli, Yau Yau Tse, Cynthia Sin Ting Chang, Malgorzata Grazyna Makowska, Dario Ferreira Sanchez, Helena Moens-Van Swygenhoven

Additive Manufacturing 59 (2022) 103173

DOI: 10.1016/j.addma.2022.103173