Fast operando X-ray radiography experiments reveal the mechanisms for cracking during 3D laser printing of a Ni-based superalloy. This new technique can be used process optimisation, validation of thermo-mechanical simulations, or the development of new materials for laser-based additive manufacturing.

Laser powder bed fusion (L-PBF) is a versatile additive manufacturing (AM) process that can print geometrically complex metal parts for a variety of applications. However, poor control of defect formation during processing hampers its widespread industrial adoption. Many materials suffer from a high crack susceptibility during L-PBF, which results in degraded mechanical properties, and is an obstacle to the certification of critical parts.

The CM247LC nickel-based superalloy is a γ´-strengthened Ni superalloy, which is of particular interest due to its excellent mechanical, creep, wear, and oxidation properties at both ambient and elevated temperatures. However, this alloy contains high amounts of Al and Ti and is considered vulnerable to cracking due to L12 Ni3 (Al, Ti) precipitation.

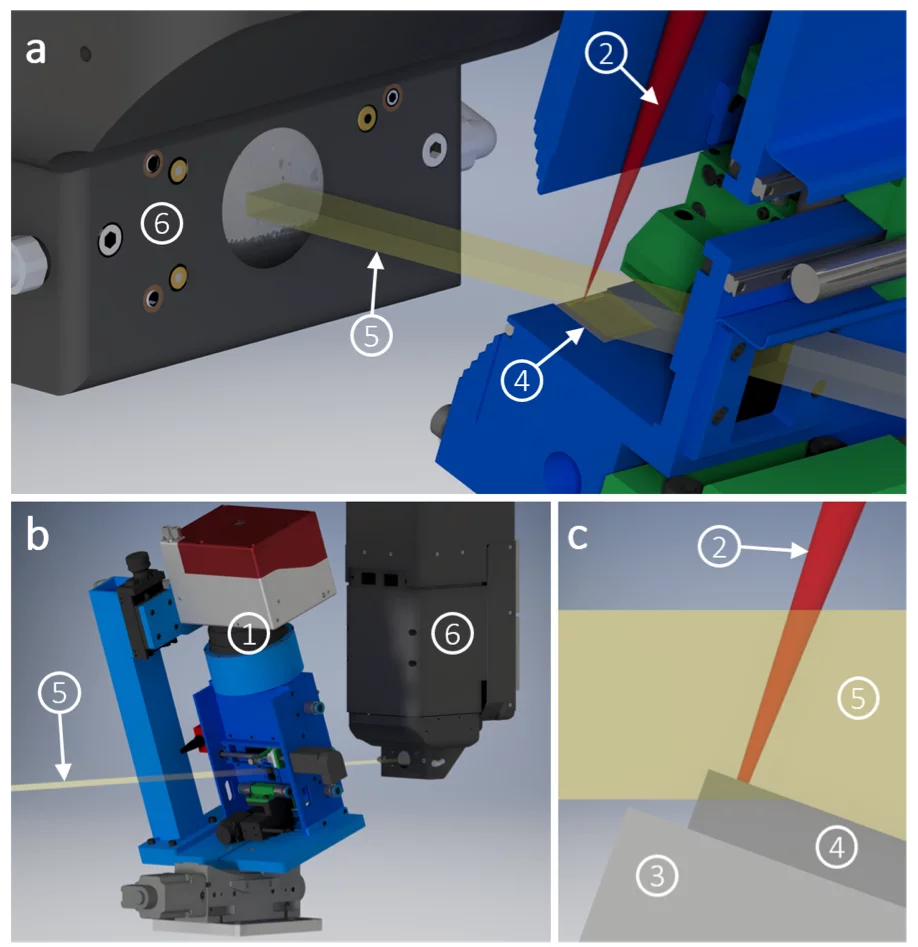

To unveil the actual cracking mechanisms, we have employed for the first time high-speed synchrotron X-ray radiography in combination with a miniaturized L-PBF setup that reproduces real processing conditions. These operando experiments were performed at the TOmographic Microscopy and Coherent rAdiology experimenTs (TOMCAT) beamline of the Swiss Light Source. Two distinct crack-related features could be observed: 1) the formation, growth, and remelting of cracks after interaction with the melt pool, and 2) the growth of existing cracks after interaction with the heat-affected zone (HAZ).

The operando radiography experiments are complemented by electron microscopy observations, operando X-ray diffraction at MicroXAS and finite element simulations. This unique combination allows to unequivocally identify and separate solidification and liquation cracking mechanisms. It is anticipated these results will stimulate the development of more accurate numerical simulations of the L-PBF process, cracking criteria, and new approaches to achieve crack-free L-PBF nickel-based parts, thereby unraveling the full industrial potential of AM technologies for these alloys.

Contact

Dr. Steven Van Petegem

Structure and Mechanics of Advanced Materials

Photon Science Division

Paul Scherrer Institute

Forschungsstrasse 111, 5232 Villigen PSI, Switzerland

Telephone: +41 56 310 2537

E-mail: steven.vanpetegem@psi.ch

Original publication

Direct observation of crack formation mechanisms with operando Laser Powder Bed Fusion X-ray imaging

Hossein Ghasemi-Tabasi, Charlotte de Formanoir, Steven Van Petegem, Jamasp Jhabvala, Samy Hocine, Eric Boillat, Navid Sohrabi, Federica Marone, Daniel Grolimund, Helena Van Swygenhoven, Roland E. Logé

Additive Manufacturing 51 (2022) 102619

DOI: 10.1016/j.addma.2022.102619