Show filters

Osselet aux rayons X: une nouvelle technique révèle ses structures en un temps record

Des scientifiques du PSI démontrent avec un osselet comment les structures de matériaux biologiques peuvent être analysées en un temps record, de l’échelle nanométrique à l’échelle millimétrique.

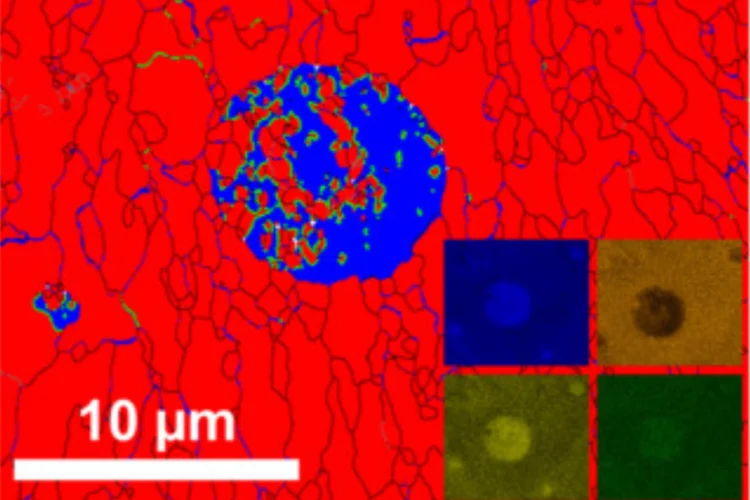

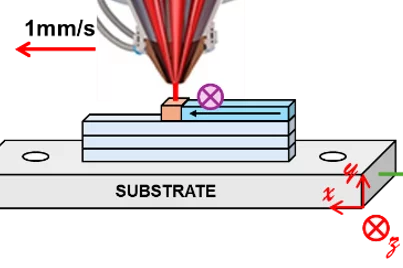

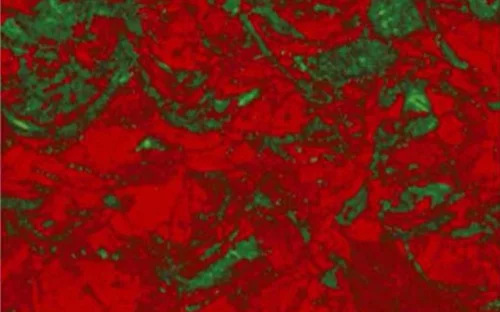

Uncovering Hidden Phases in 3D-Printed Fusion Steels

3D synchrotron X-ray mapping uncovered unexpected internal phase structures in laser-printed steels, showing how processing controls what we cannot see.

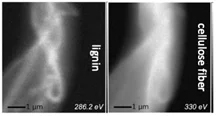

Preparing cellulose sample for soft-Xray spectro-microscopy

Different sample preparation techniques for ultrathin samples to be measured at the carbon-K-edge for chemical contrast are presented.

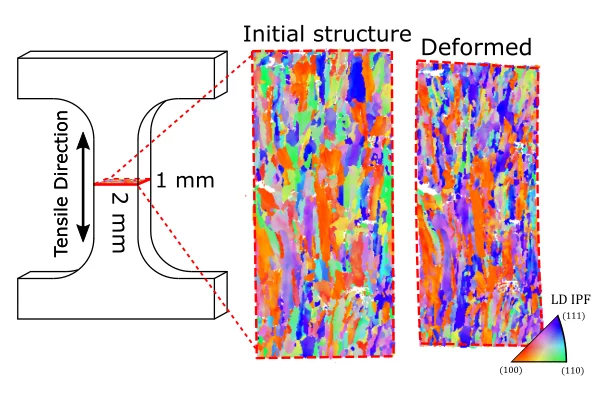

Following Twin-Formation in 3D Printed Steel

Using hard-xray microscopy to study the deformation of 3D printed steel.

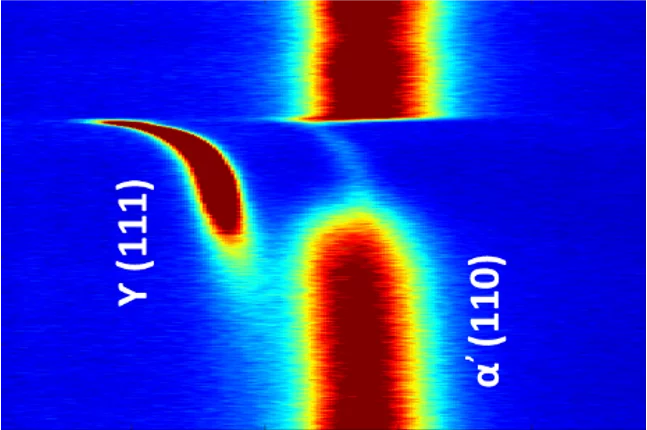

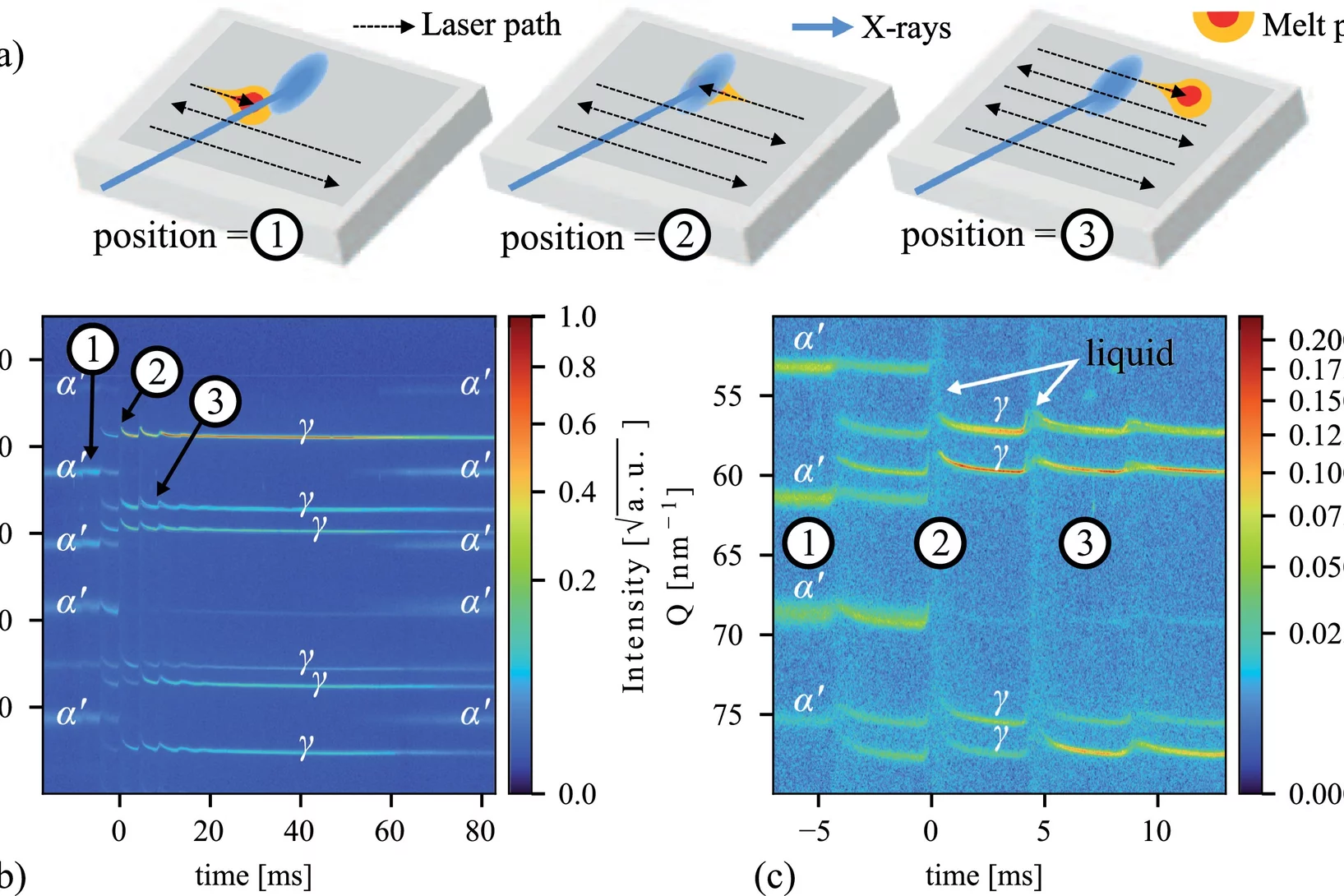

From Melt to Martensite

Real-time synchrotron X-ray diffraction reveals how different phases of steel emerge and evolve under the intense heat of laser powder bed fusion.

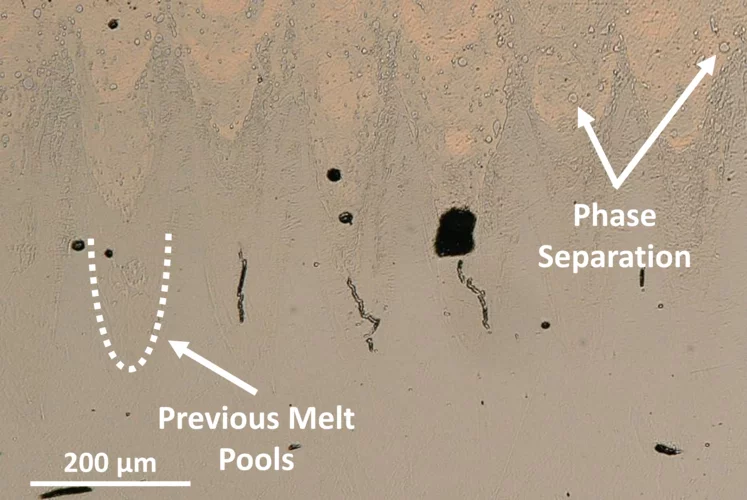

Why Ni-Cu Alloys Fail in 3D Printing

3D printing with nickel–copper alloys holds great promise — but hidden mechanisms can cause them to crack. Our latest study reveals why.

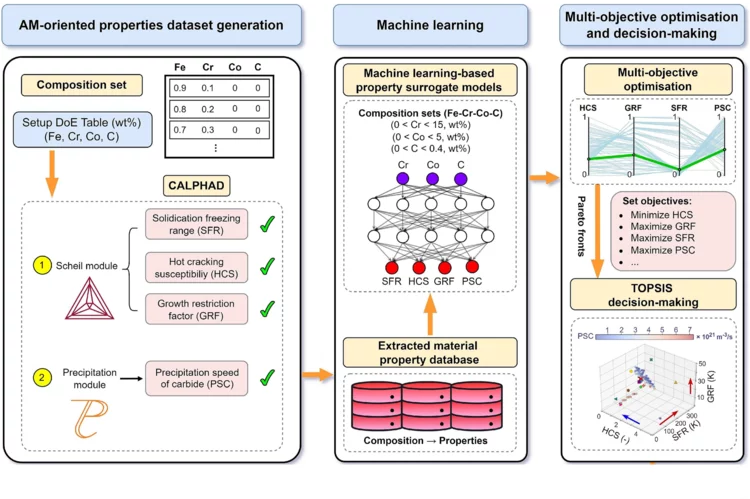

Machine Learning Accelerates Alloy Design for Additive Manufacturing

A new machine learning–designed alloy demonstrates how materials can be tailored for specific performance properties required in additive manufacturing.

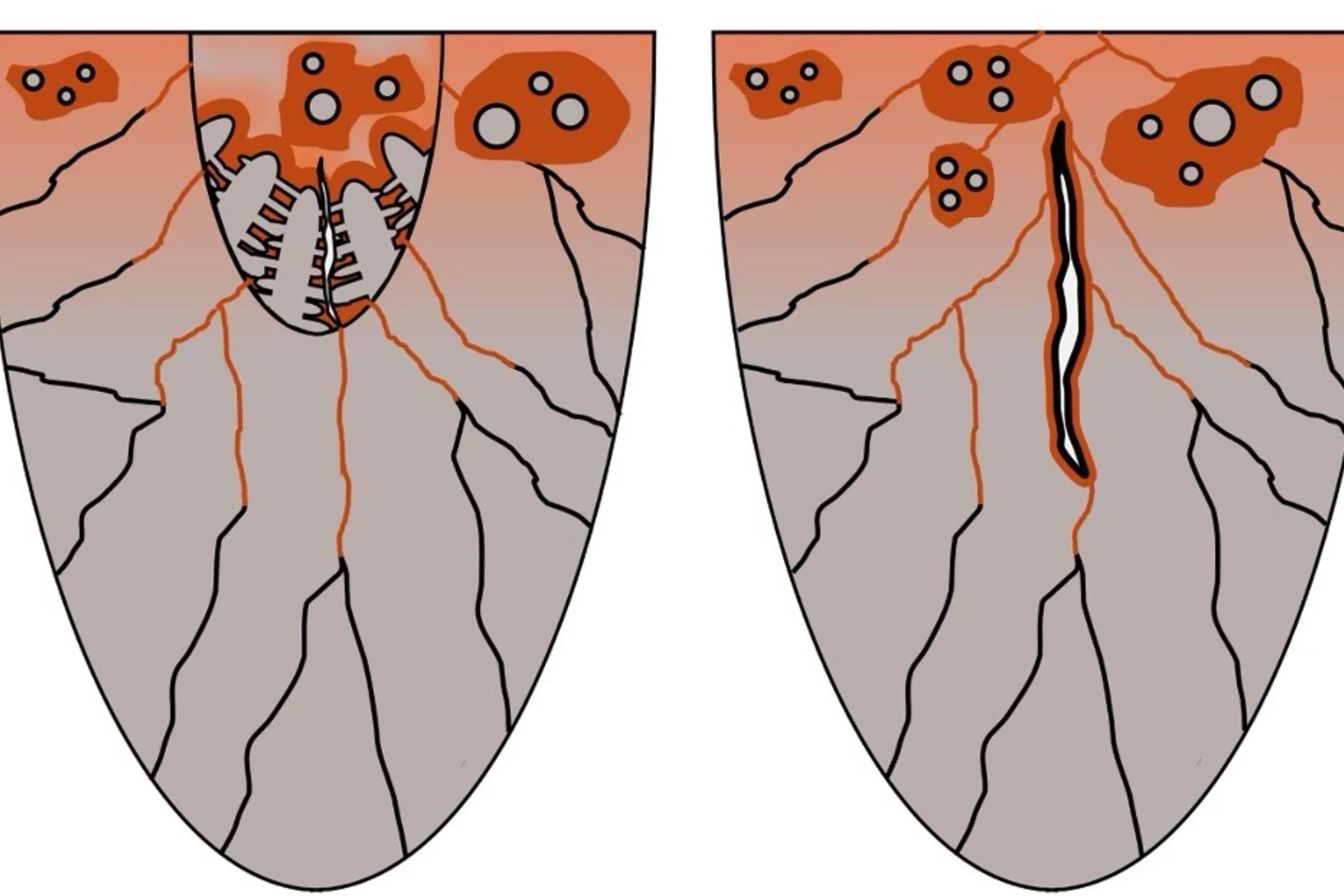

Cracking the Challenge of Steel–Copper Fusion

Why do cracks appear when joining steel and copper? We track the mechanisms in real time to find out.

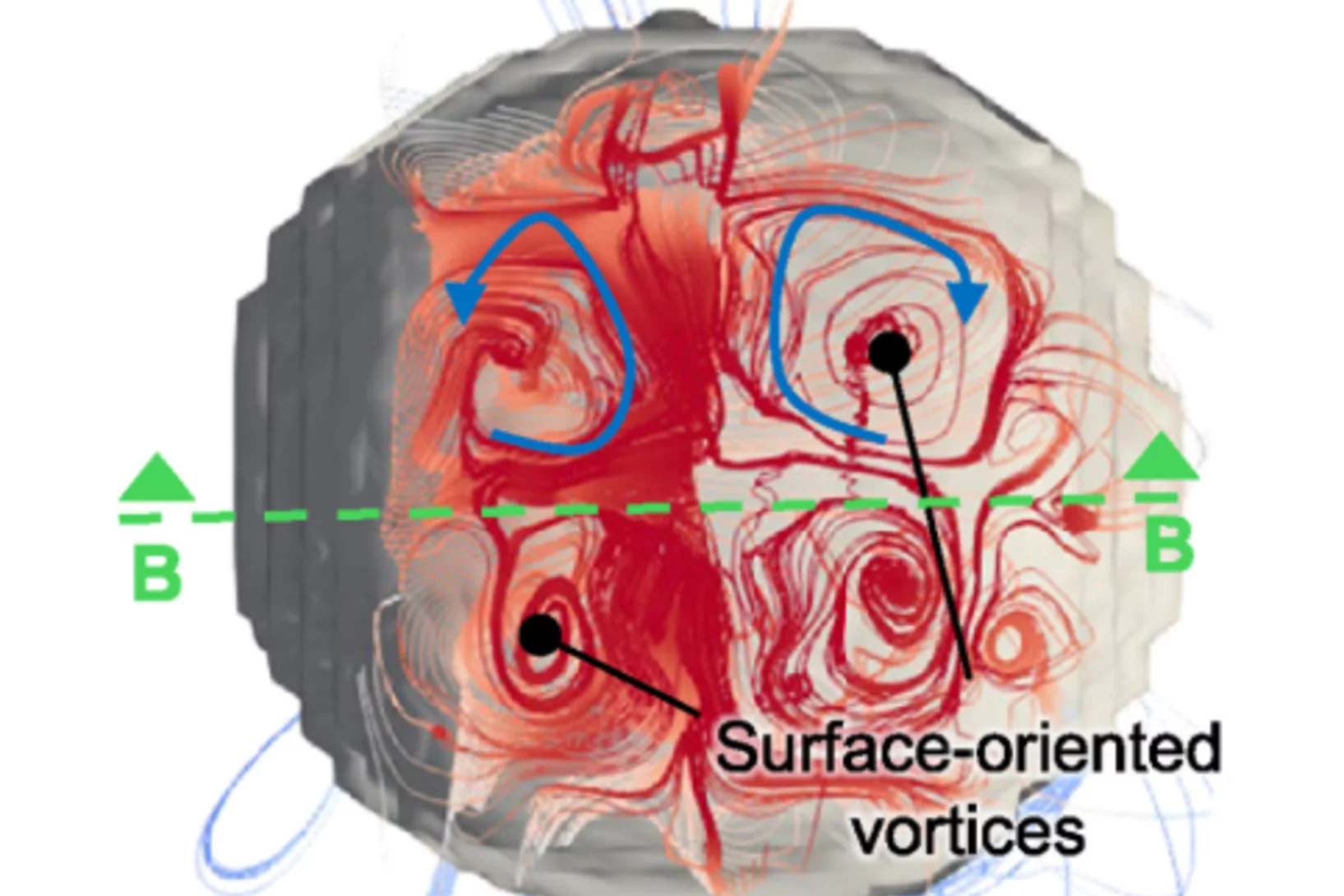

Interfacial Phase Formation in 316L–CuCrZr Hybrids

In-situ X-ray diffraction reveals how phase separation and fluid flow shape microstructure in laser-welded multi-material metal builds.

Phase by Phase: How Stainless Steel and IN625 Solidify Together

Where steel meets superalloy: real-time X-ray snapshots reveal how composition and cooling shape metal during 3D printing

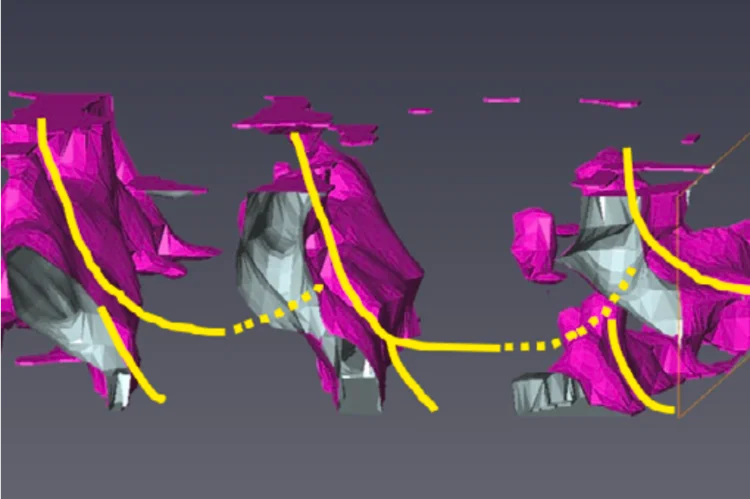

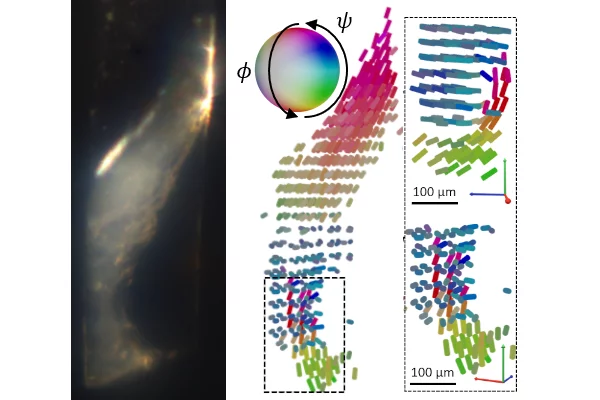

Nanostructure orientation in 3D with visible light by Tomographic Müller-Polarimetric Microscopy

We developed a new method, tomographic Müller-polarimetric microscopy (TMPM), that allows to retrieve at three-dimensional microscopic resolution the nanoscale structural information of the ultrastructure probed with polarized light in a non-destructive manner using a low cost and experimentally simple optical setup.

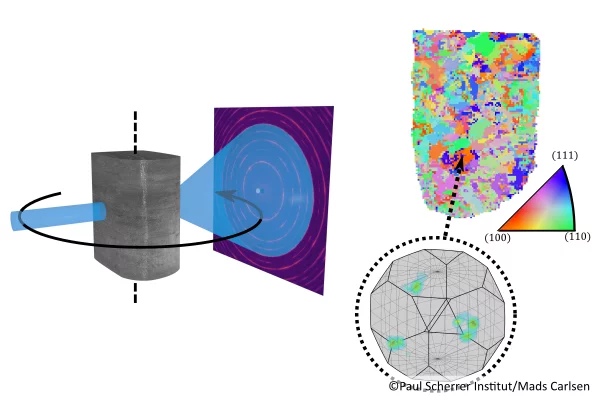

Mapping crystallite orientation in bulk polycrystals

A new experimental technique allows the orientation distribution of small-grained polycrystal materials to me mapped in 3D.

Rethinking 3D Printing for ceramics

Using a powerful combination of in-situ X-ray imaging and high-fidelity simulations, researchers uncover how alumina behaves under laser-based 3D printing—paving the way for more reliable ceramic additive manufacturing.

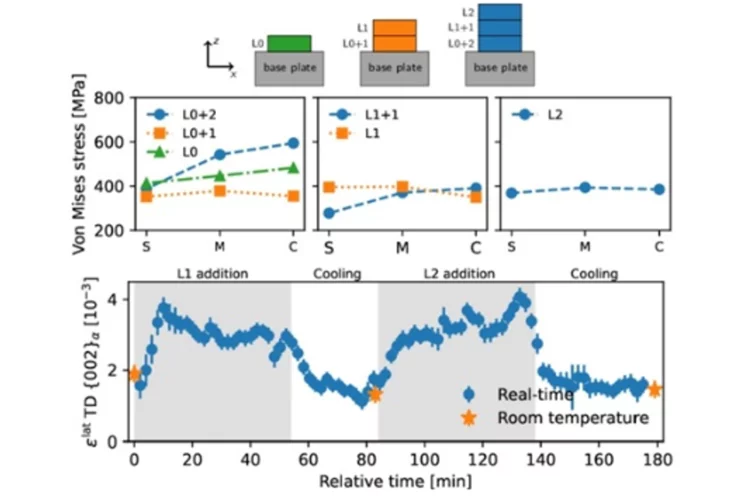

Texture and residual stress evolution during 3D printing

Discover how advanced neutron diffraction sheds light on the evolution of stress and texture in 3D-printed duplex stainless steel.

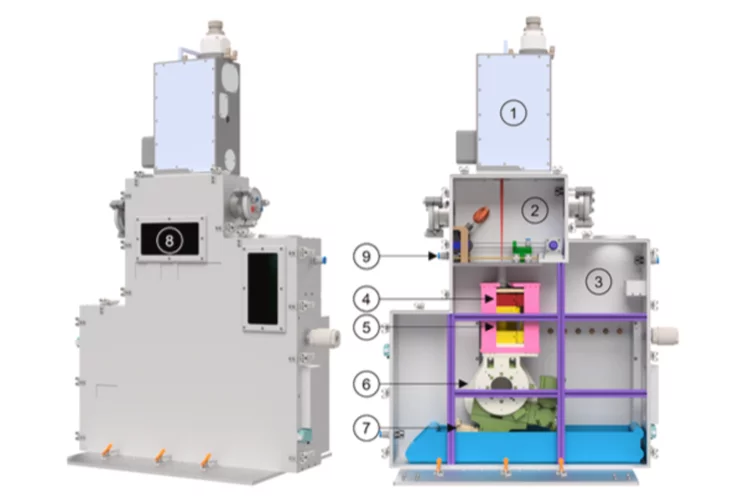

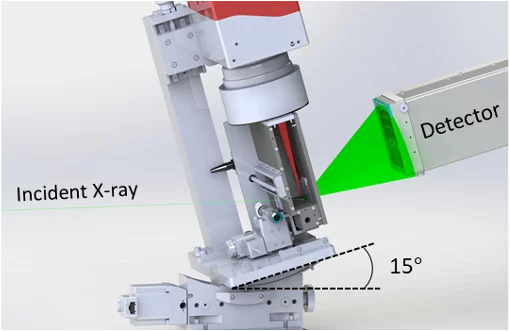

Operando Neutron Characterization During 3D Printing

A new laser powder bed fusion device enables real-time neutron diffraction and imaging, providing detailed insights into structural evolution, defect formation, and temperature mapping during metal additive manufacturing.

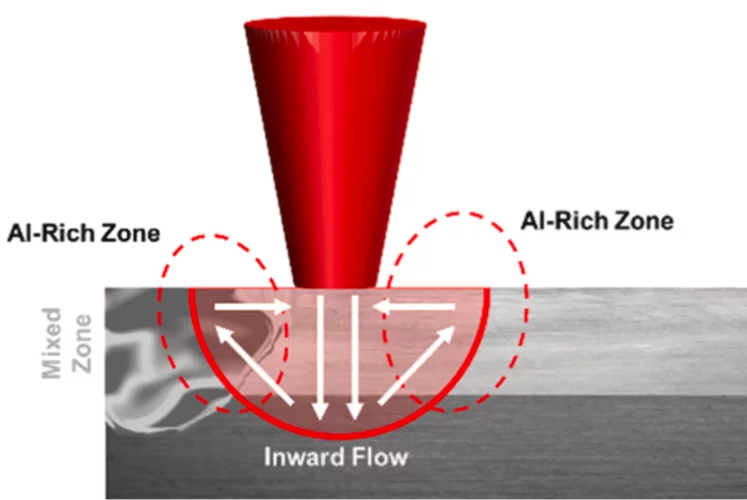

Mitigating Cracks in Multi-Material Printing

Integrating metallic powders with thin foils in laser powder bed fusion can reduce interfacial cracks and improve microstructure quality in titanium-aluminum multi-material printing.

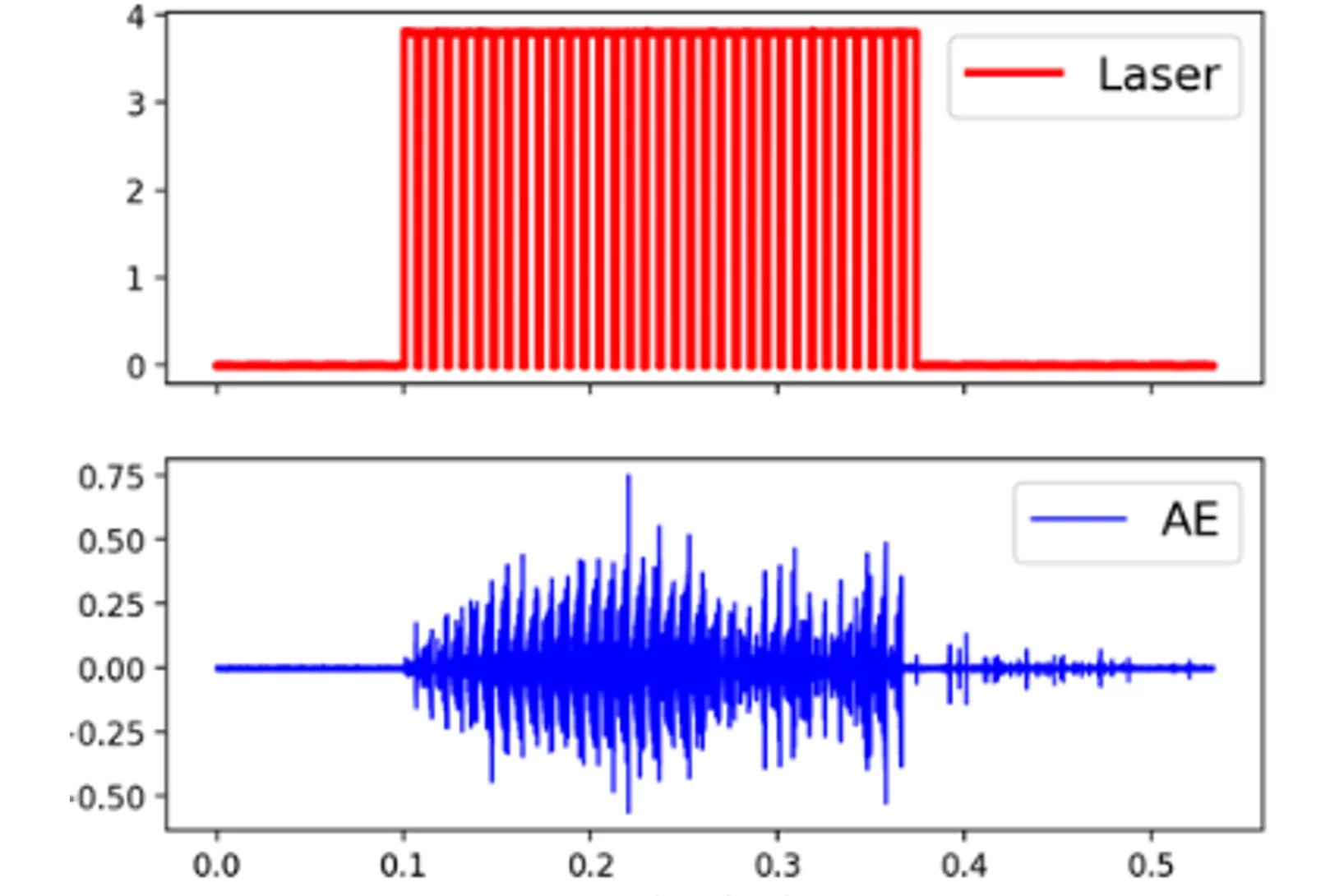

Acoustic emission signature of a martensitic transformation

Acoustic emission monitoring in 3D printing: real-time insights into martensitic phase transformations and crack formation.

The Tipping Point!

Exciting to see that some of our research on Narwhal tusk made it into an educational videogame about climate change in the Arctic and its impact on some of its inhabitants!

Observing laser-induced recrystallization

Synchrotron X-ray diffraction sheds light on laser-induced local recrystallization .

Listening for Defects as They Happen

Experiments at the Swiss Light Source SLS help resolve a long-standing debate surrounding metal 3D laser printing.

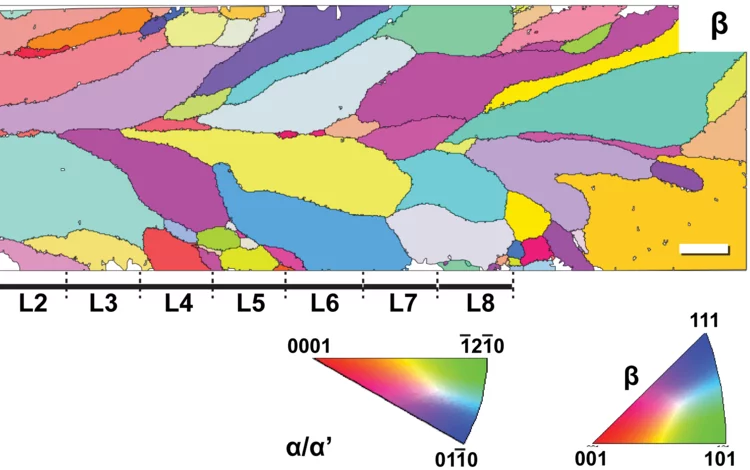

Microstructural control of additively manufactured Ti-6Al-4V

In-situ Selective Laser Heat treatment is applied to induce martensite decomposition in Ti-6Al-4V

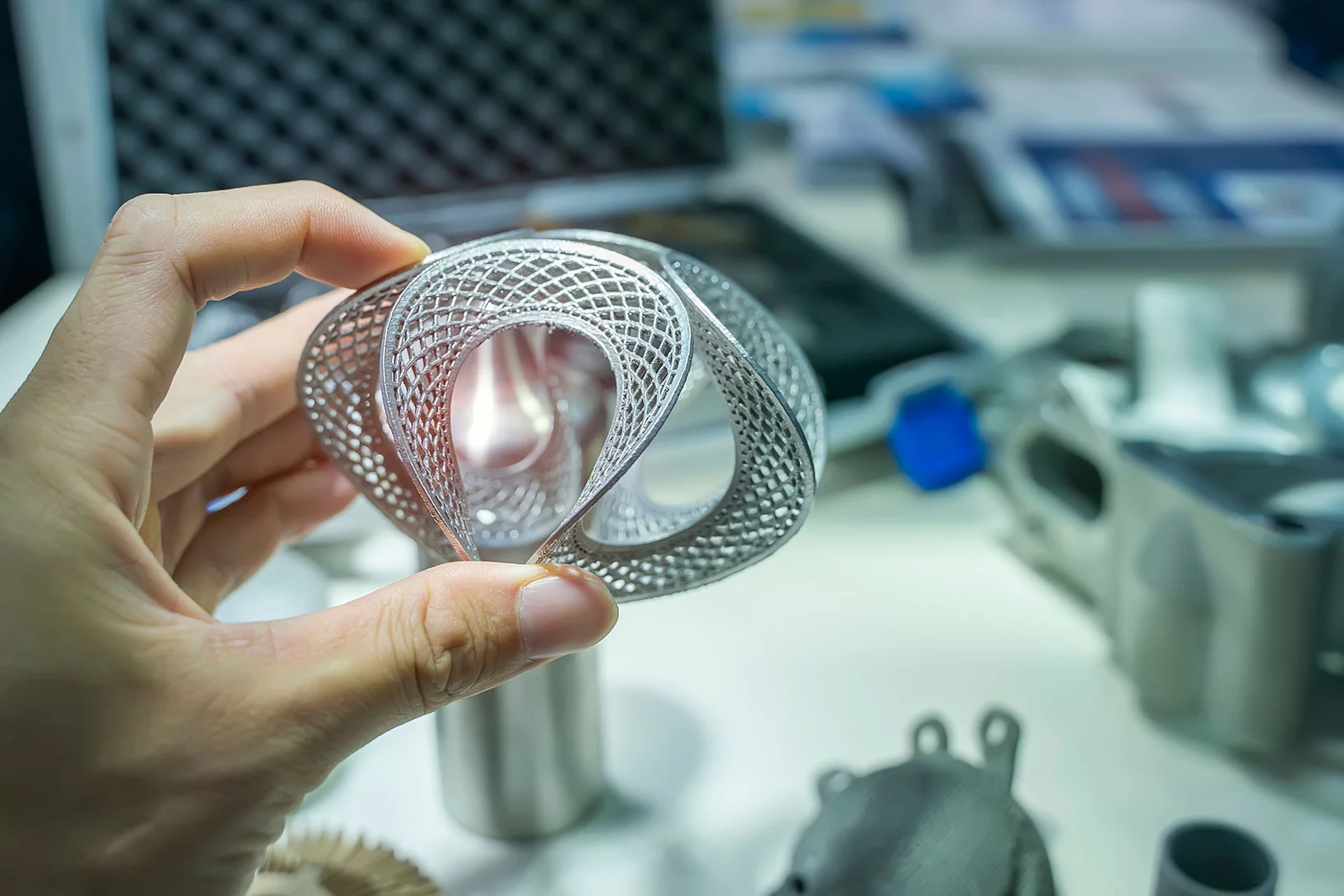

Additive manufacturing of alloys with programmable microstructure and properties

Using laser powder bed fusion (LPBF) technology, we devise special processing strategies to ‘program’ the thermal stability of the as-printed alloy, such that it is possible to decide, a priori, how the material’s microstructure will evolve upon heat treatment

Aperçus 3D d’un procédé de fabrication novateur

Fabriquer des formes complexe avec l’impression 3D

On the trail of blue bones

The bones of the tree hollow toad tree frog are turquoise blue. Our team is currently investigating the nanostructure of the bone and its significance for the frog.

MUMOTT V1.0 released!

We are happy to announce the release of MUMOTT (multi-modal tensor tomography) 1.0, an all-Python package for the analysis of tensor tomography measurements!

A close look at temperature profiles during laser 3D printing

Operando X-ray diffraction was used to measure process zone temperatures in laser powder bed fusion and compared with finite element simulations.

X-rays make 3D metal printing more predictable

Insights into the microscopic details of 3D printing from the Swiss Light Source SLS could propel the technology toward wider application

Solidification modes during additive manufacturing

The thermal conditions during laser-based additive manufacturing are inferred from high-speed X-ray diffraction data and can be linked to a model for rapid solidification.

Thermal cycling during 3D laser printing

High-speed in situ X-ray diffraction is used to measure temperature profiles and cooling rates during 3D printing of a a Ti-6Al-4V single-track wall.

In situ alloying during additive manufacturing

In situ alloying is an effective method to engineer microstructures of additively manufactured Ti6Al4V3Fe alloys.