A novel monitoring strategy for laser powder bed fusion processes based on a hybrid deep learning model is presented. It combines convolutional neural networks with long-short term memory. This model allows the classification of printing regimes with an accuracy of 98% across variable time-scales.

Harnessing the full potential of the metal-based Laser Powder Bed Fusion process (LPBF) relies heavily on how effectively the overall reliability and stability of the manufactured part can be ensured. To this aim, the recent advances in sensorization and processing of the associated signals using Machine Learning (ML) techniques have made in situ monitoring a viable alternative to post-mortem techniques such as X-ray tomography or ultrasounds for the assessment of parts. Indeed, the primary advantage of in situ monitoring over post-mortem analysis is that the process can be stopped in case of discrepancies, saving resources. Additionally, mitigations to repair the discrepancies can also be performed. However, the in situ monitoring strategies based on classifying processing regimes reported in the literature so far operate on signals of fixed length in time, constraining the generalization of the trained ML model by not allowing monitoring processes with heterogeneous laser scanning strategies.

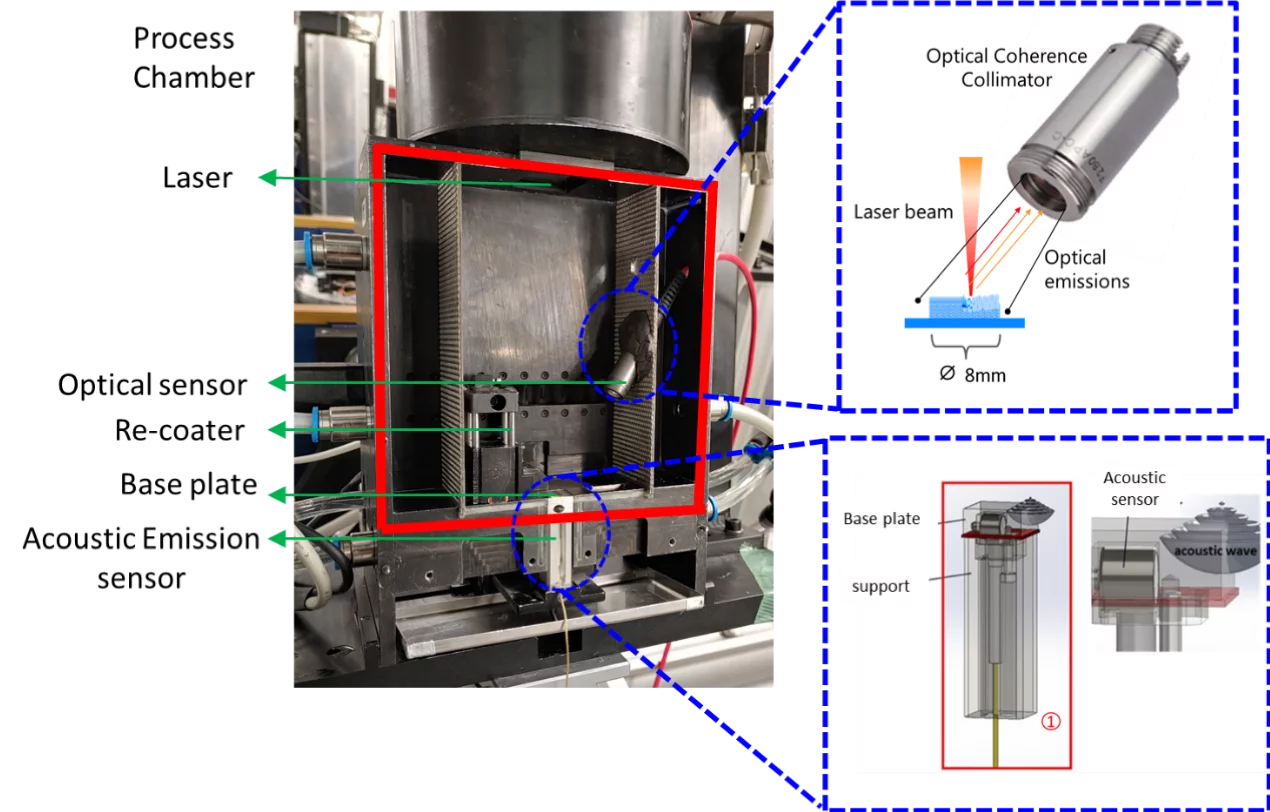

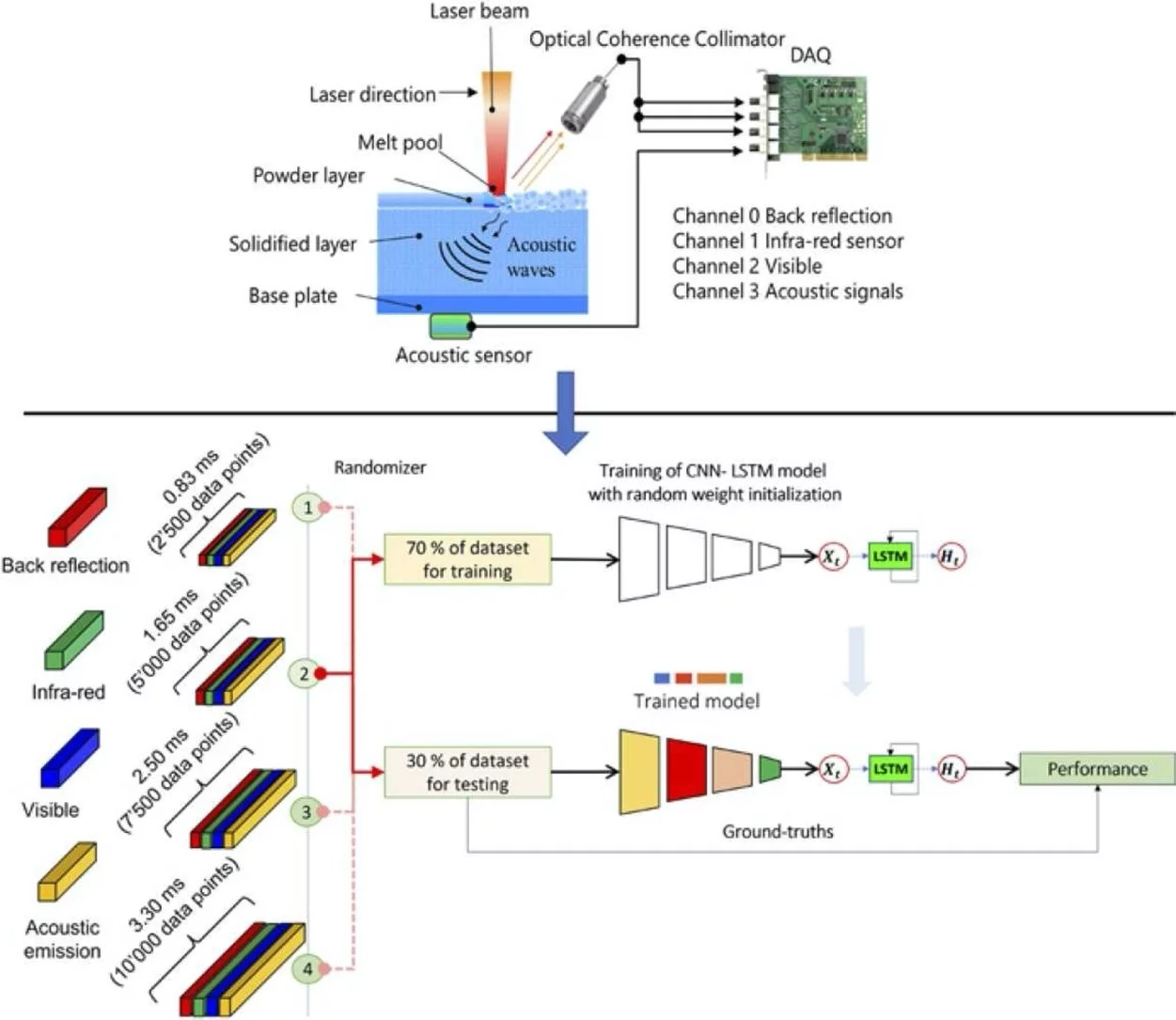

In this work, we bridge this gap by developing a hybrid Deep Learning (DL) model by combining Convolutional Neural Networks (CNNs) with Long-Short Term Memory (LSTM) that can operate over variable time-scales. The proposed hybrid DL model was trained on signals obtained from a heterogeneous time-synced sensing system consisting of four sensors, namely back reflection (BR), Visible, Infra-Red (IR), and structure-borne Acoustic Emission (AE). The signals captured different phenomena related to the LPBF process zone and were used to classify three regimes: Lack of Fusion (LoF), conduction mode and Keyhole. Specifically, these three regimes were induced by printing cubes out of austenitic Stainless steel (316L) on a mini-LPBF device with operando high-speed synchrotron X-ray imaging and signal acquisition with the developed heterogeneous sensing system. The operando X-ray imaging analysis ensured that the regimes correlated with the defined process parameters. During the validation procedure of the trained hybrid DL model, the model predicted three regimes with an accuracy of about 98% across various time scales, ranging from 0.5 ms to 4 ms. In addition to tracking the model performance, a sensitivity analysis of the trained hybrid model was conducted, which showed that the BR and AE sensors carried more relevant information to guide the decision-making process than the other two sensors used in this work.

Contact

Dr. Steven Van Petegem

Structure and Mechanics of Advanced Materials

Photon Science Division

Paul Scherrer Institute

Forschungsstrasse 111, 5232 Villigen PSI, Switzerland

Telephone: +41 56 310 2537

E-mail: steven.vanpetegem@psi.ch

Original publication

Deep Learning-based Monitoring of Laser Powder Bed Fusion Process on Variable Time-Scales Using Heterogeneous Sensing and operando X-ray Radiography Guidance

Vigneashwara Pandiyan, Giulio Masinelli, Navarre Claire, Tri Le-Quang, Milad Hamidi-Nasab, Charlotte de Formanoir, Reza Esmaeilzadeh, Sneha Goel, Federica Marone, Roland Logé, Steven Van Petegem, Kilian Wasmer

Additive Manufacturing 58 (2022) 103007

DOI: 10.1016/j.addma.2022.103007