A miniaturized laser powder bed fusion (LPBF) device has been developed for operando X-ray diffraction and imaging experiments at synchrotron facilities. The system is portable and reproduces the core functionalities of a commercial LPBF machine, enabling in situ characterization of the additive manufacturing process under realistic processing conditions.

Description

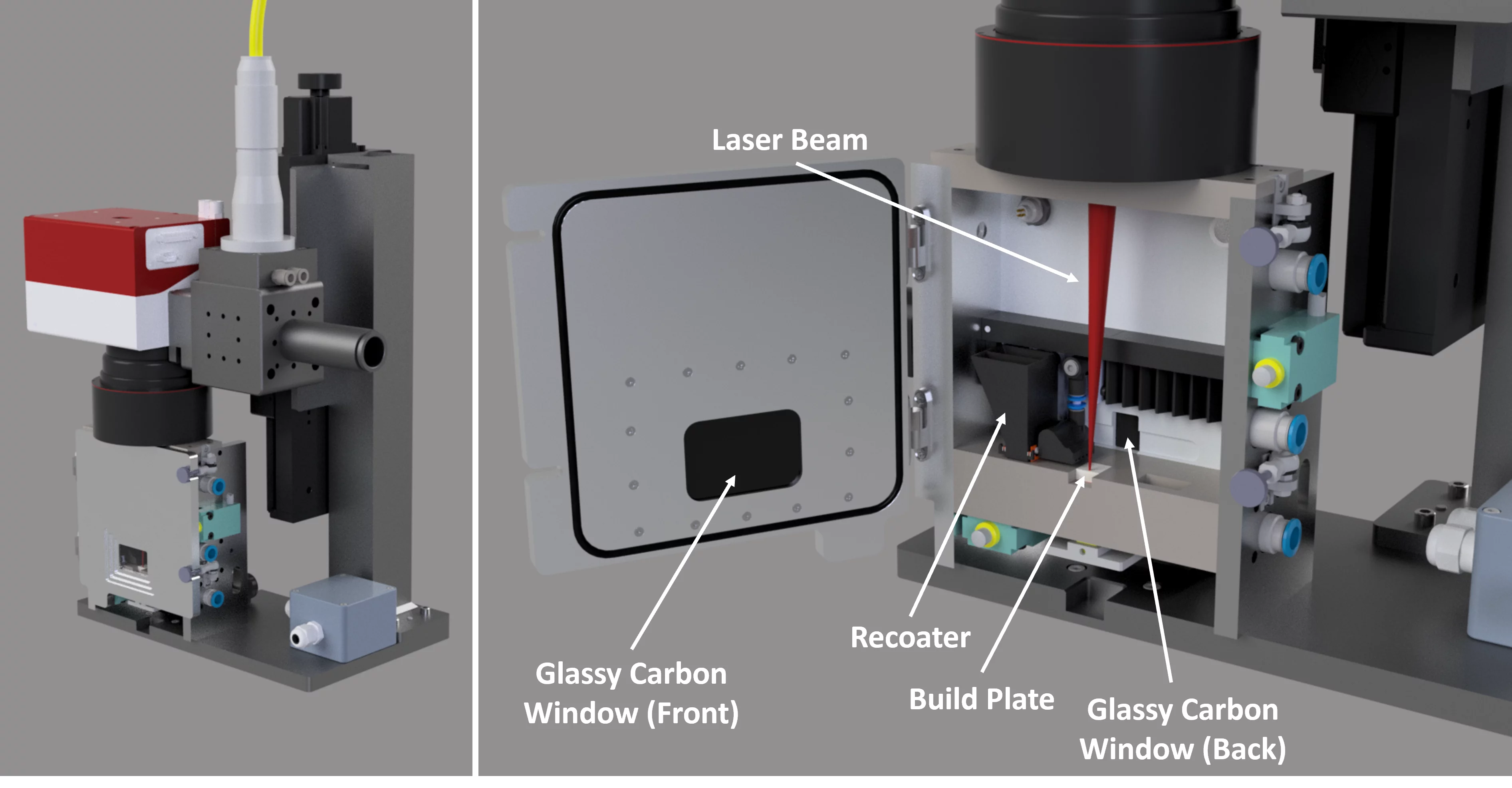

The miniSLM system employs a collimated infrared laser beam that is steered by a two-axis scanning unit into the main processing chamber. The laser is focused onto a 12 × 12 mm² build platform, which is vertically translatable over a 12 mm travel range with sub-micron positioning resolution.

The build platform can be actively heated using a silicon nitride resistive heater, allowing controlled thermal conditions during processing. Powder recoating is achieved via a hopper-based feeding system, in which the powder reservoir is translated across the build plate using a motor-driven spindle assembly, ensuring reproducible layer deposition.

The device is fully enclosed, preventing the escape of laser radiation or powder particles. The processing chamber is continuously purged with high-purity argon gas. Manual flow control enables the creation of a slight overpressure, effectively minimizing oxygen ingress and preventing oxidation during processing.

Thermal management of the entire system—including the laser source, scanning optics, and build chamber—is provided by a closed-loop air–water heat-exchange chiller. An inline optical camera is integrated for laser alignment and real-time inspection of the powder bed.

In addition to X-ray–based characterization, the miniSLM platform is designed to be modular and extensible. The device can be equipped with additional in situ sensing modalities, including acoustic emission sensors (both airborne and structure-borne) as well as optical sensors, enabling multi-physics monitoring of the LPBF process. This flexibility allows correlated analysis of thermal, mechanical, and microstructural phenomena during fabrication.

The video below illustrates the fundamental principles of operando X-ray diffraction during LPBF using the miniSLM system.

(Credit: Paul Scherrer Institute/Mahir Dzambegovic)

Technical details

| Laser | ||

| Type | redPOWER® continuous wave Fiber Laser | |

| Wavelength | 1070nm | |

| Maximum power | 500W | |

| Spot size | 25 µm - 250 µm | |

| Device | ||

| Dimensions | 15mm x 20mm x 30mm | |

| Build plate | 12mm x 12mm | |

| Maximum build height | 8mm | |

| Maximum temperature | 150°C | |

| Maximum angle tilt stage | 20° |

Selected publications

-

Hamidi Nasab M, Masinelli G, de Formanoir C, Schlenger L, Van Petegem S, Esmaeilzadeh R, et al.

Harmonizing sound and light: X-ray imaging unveils acoustic signatures of stochastic inter-regime instabilities during laser melting

Nature Communications. 2023; 14: 8008 (14 pp.). https://doi.org/10.1038/s41467-023-43371-3

DORA PSI -

Gao S, Li Z, Van Petegem S, Ge J, Goel S, Vas JV, et al.

Additive manufacturing of alloys with programmable microstructure and properties

Nature Communications. 2023; 14(1): 6752 (11 pp.). https://doi.org/10.1038/s41467-023-42326-y

DORA PSI -

Hocine S, Van Swygenhoven H, Van Petegem S

Verification of selective laser melting heat source models with operando X-ray diffraction data

Additive Manufacturing. 2021; 37: 101747 (16 pp.). https://doi.org/10.1016/j.addma.2020.101747

DORA PSI -

Hocine S, Van Petegem S, Frommherz U, Tinti G, Casati N, Grolimund D, et al.

A miniaturized selective laser melting device for operando X-ray diffraction studies

Additive Manufacturing. 2020; 34: 101194 (9 pp.). https://doi.org/10.1016/j.addma.2020.101194

DORA PSI -

Hocine S, Van Swygenhoven H, Van Petegem S, Chang CST, Maimaitiyili T, Tinti G, et al.

Operando X-ray diffraction during laser 3D printing

Materials Today. 2020; 34: 30-40. https://doi.org/10.1016/j.mattod.2019.10.001

DORA PSI