Fusion power promises an almost limitless, low carbon energy supply, urgently needed to address the climate emergency and meet growing energy demands. However, the intense radiation produced in the process causes defects to form in the structure of the reactor materials. These defects can dramatically degrade material properties.

Remarkably, most of the defects radiation produces are too small to be probed by electron microscopy, the mainstay for atomic scale defect characterisation. While these “invisible” defects are each only a few atoms in size, high concentrations of these defects can cause dramatic changes: Embrittlement, increase in hardness by up to 100%, reduction in thermal diffusivity by more than 50% and swelling by several percent. A new paradigm that has recently emerged from our research is to use X-ray diffraction measurements of lattice strain to indirectly probe “invisible” defects via the strain fields they cause. However, these measurements could only resolve defect populations at the micro-scale – far too coarse to shed light on the nano-scale interactions that govern defect structure formation and evolution.

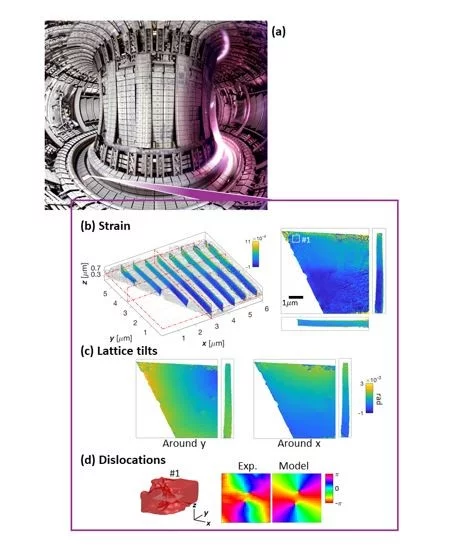

Using the excellent brilliance and coherence of the ID01 beamline at ESRF, a team of researchers from Institut Fresnel, the Diamond Light Source, the Paul Scherrer Institute and the University of Oxford have developed a new microscopy technique that allows the measurement of lattice strain in extended objects at the nano-scale. Lead author of the study Dr. Peng Li explains: “Our technique called Bragg Ptychography uses coherent diffraction patterns produced by a sub-micron X-ray beam rastered across the sample. From these diffraction patterns we can reconstruct the morphology of the sample with about 20 nm 3D resolution. Importantly, we can reconstruct in 3D how the crystal lattice within the sample has been distorted, revealing the presence of otherwise invisible defects.”

The key advance is that, for the first time, the new reconstruction approach allows taking imperfections of the illuminating X-ray beam into account and, through up-sampling of the diffraction data, enables a greatly extended field of view. Prof. Virginie Chamard, who has spearheaded the worldwide development of the Bragg ptychography technique, elaborates: “The new reconstruction approach is much more robust and allows crisper, higher quality reconstructions while requiring a smaller amount of experimental data. We estimate that this corresponds to an improvement in data acquisition efficiency by more than a factor of 10.”

The authors applied the new microscopy technique to tungsten, the front-runner material for fusion reactor armour. They were able to image in 3D the complex lattice distortions caused by helium injected into the lattice, which mimics the damage expected to form in armour components during fusion reactor operation. Prof. Felix Hofmann from the University of Oxford explains: “Using Bragg ptychography has finally allowed us to actually view in 3D how atomic scale crystal defects caused by helium ion-irradiation are distributed within the tungsten matrix. Remarkably, we found that fewer defects exist near grain boundaries, suggesting that perhaps nano-structured materials may offer better radiation resistance. The 3D resolution of this technique has also uniquely enabled us to exclude unwanted artefacts at sample surfaces that are caused by sample preparation from our analysis. This is very important as it really allows us to pin down what defects are caused by the helium exposure. These new insights are key to developing new strategies for designing the next generation of radiation damage resistant materials.”

The data for this study was collected before the ESRF-EBS upgrade, after which the ID01 beamline delivers over 20 times more coherent flux to the sample position. Dr. Steven Leake from the ID01 beamline explains: “Bragg ptychography offers spatial resolution below the beam size on extended samples and is the most efficient way to use photons, as the resolution is proportional to the incident photon flux. Using this method will allow us to protect sensitive samples from X-ray damage, whilst obtaining the highest quality images possible. The knock on effects are an increased throughput of the beamline and the time available for other scientists to come and exploit these methods to solve their scientific questions.”

The future is bright when it comes to Bragg ptychography Dr. Nick Phillips explains: “Looking ahead, our developments will be key to making this a microscopy technique that can be used by non-specialists across a wide range of instruments. With diffraction limited storage rings like SLS 2.0, we can expect additional improvements in the near future.”

These exciting prospects are fuelling efforts to study how atomic scale crystal defects influence the behaviour of all sorts of materials that underpin technologies central to modern life.

Contact

Nicholas Phillips

Laboratory for Macromolecules and Bioimaging

Photon Science Divison PSD

Paul Scherrer Institute PSI

nicholas.phillips@psi.ch

Original Publication

Peng Lia, b, Nicholas W. Phillipsc, d, Steven Leakee, Marc Allaina, Felix Hofmannc, Virginie Chamarda

Nature Commun. 12, 7059 (2021). https://doi.org/10.1038/s41467-021-27224-5

(a) Aix-Marseille Univ, CNRS, Centrale Marseille, Institut Fresnel, Marseille (France). (b) Diamond Light Source, Harwell Science and Innovation Campus, (Didcot) (UK). (c) Department of Engineering Science, University of Oxford, Oxford (UK). (d) Paul Scherrer Institut, Villigen (Switzerland). (e) ESRF – The European Synchrotron, Grenoble (France).