Water management is crucial to the successful cold-start in polymer electrolyte fuel cells (PEFCs). The sudden freeze of supercooled water blocks the reactant gas in the cathode and causes rapid voltage failure. In this work, we statistically evaluated the effects of the gas diffusion layer (GDL) substrate, size, saturation, and the coating loads and methods of hydrophobic polymer on the freezing probability of supercooled water by differential scanning calorimetry (DSC).

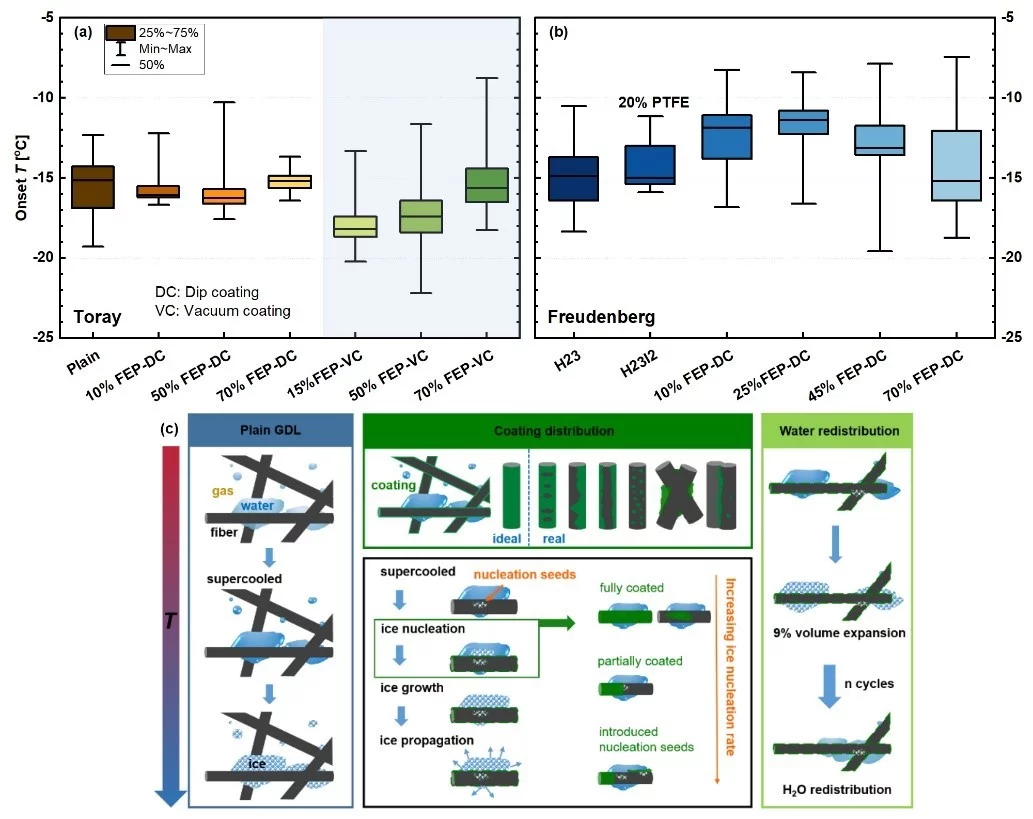

Pure water remains as supercooled liquid, until it encounters nucleation seeds or the temperature reaches below the onset freezing point, T_onset. Ice forms on nuclei, grows, and eventually spreads rapidly throughout the GDL. Statistical DSC ramping measurements were performed at a sweeping rate of 5 K/min between -35℃ and 10℃. Fluorinated ethylene propylene (FEP) coating was applied to untreated Toray and Freudenberg GDLs with loadings from 10 to 70 wt.% by dip-coating (DC) and vacuum-coating (VC). Samples were then punched to 6 mm in diameter and saturated with ultrapure water (R > 18.8 MΩ) in the vacuum chamber (20 mbar). The probability of freezing increased marginally with sample size, while it was not affected noticeably by the saturation level. T_onset distributions were achieved by 5-10 samples with 20 repetitions, as shown in the Figure. Regardless of porosity, pore size distribution, and fiber structure, plain Toray and Freudenberg showed comparable T_onset distributions, with the median T_onset and relative frequency peaking at -15℃ (Figure a and b). We observed similar or higher freezing probability for the samples with hydrophobic coatings (dip-coated, 10-70 wt. %). This was due to the uneven distribution of coating, resulting in a partial surface coverage and isolation of ice nucleation seeds from the supercooled water. With the FEP distribution improved by vacuum coating, the probability of freezing was noticeably decreased with 15% FEP loading, and one freezing event occurred below -20℃. This late crystallization phenomenon was consistently observed in one of the Toray-50% FEP-VC samples over 20 cycles, with T_onset distributed between -20℃ and -22℃. This suggests that crystallization can be inhibited, given that hydrophobic coating effective covers the GDL fibers. However, morphological features of the coating, such as roughness and defects, can also be ice nucleation seeds, increasing the chances of freezing, as seen from the T_onset distributions of Toray and Freudenberg with 70% FEP coating (Figure c). Inter-sample variation was more pronounced than the inter-cycle variation because of the small sample size used in this work and distribution/redistribution of water during cycling, which was promoted by the volume expansion of the ice (9%) and the hydrophobicity of the GDL (Figure c). This helps to understand the in situ cold start of PEFC, since water is continuously generated in the CL and redistributed in the GDL. Therefore, for cold starts, even the T_onset for a given cycle may be random; given that the numbers of samples and cycles are representative, the probability of freezing is predictable from the T_onset distribution obtained from statistical ex situ DSC measurements. GDL surface can be modified by direct fluorination and electro-grafting to improve the cold start capability of PEFC, as these surface treatments enable a homogeneous coating of the carbon fibers without compromising porosity or introducing seeds. Another strategy is to prevent the ice propagation chemically or mechanically, which facilitates diffusion of reactant gas in the unfrozen regions in GDL, given that some regions are blocked by ice.

Contact

Dr. Pierre Boillat

Head of Neutron Imaging of Electrochemical Systems Group

Paul Scherrer Institut

5232 Villigen PSI

Switzerland

Telephone: +41 56 310 27 43

E-mail: pierre.boillat@psi.ch

Ms. Wenmei Liu, PhD student

Neutron Imaging of Electrochemical Systems Group

Paul Scherrer Institut

5232 Villigen PSI

Switzerland

Telephone: +41 56 310 27 46

E-mail: wenmei.liu@psi.ch

Original Publication

in press

W. Liu et al.

in press (2022)

DOI: tbd

Acknowledgement to Funding Agency

The authors thank the SNSF for funding this project under the grant 185085.