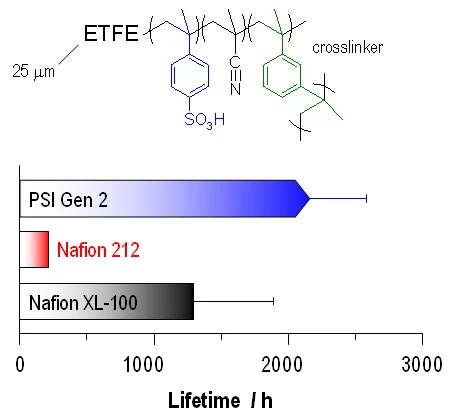

Components for the polymer electrolyte fuel cell (PEFC) are required to show high performance and durability under application relevant conditions. Furthermore, for commercial viability the materials and processes for component fabrication need to be of los cost. The polymer electrolyte membrane developed at PSI on the basis of the radiation grafting technique has the potential of being produced in cost-effective manner. In recent years, we have collaborated with the Belenos Clean Power to further develop the membrane to commercial competitiveness. We managed, by careful analysis and optimization of the synthesis conditions, to close the performance gap to commercial membranes (Nafion). The durability of the PSI membranes was evaluated in a dynamic (accelerated) test to simulate an automotive cycle. Our membrane showed a durability much superior to that of the unreinforced commercial Nafion 212 membrane. It even outlasted the reinforced and chemically stabilized Nafion XL-100 membrane, a state-of-the-art material for challenging automotive applications. Beyond fuel cells, the radiation grafting technology can be adapted to design polymer electrolyte materials for other electrochemical applications of current and future interest, such as water electrolyzers, redox flow batteries and next-generation lithium batteries.