How would you like your protein today? Cryo-cooled, squirted from a liquid jet or…levitated? Every protein is different, and in X-ray crystallography different proteins – and different scientific questions - need different tricks. At the Swiss Light Source, a recent addition to the sample delivery menu presents proteins to the beam in an acoustically levitated droplet, offering unique opportunities for drug binding studies as well as advantages in throughput. The latest development serves up rapidly spinning ‘hoverboards’ to hold delicate membrane protein crystals: a crucial step for drug discovery applications.

We have cryogenic cooling to thank for a revolution in protein crystallography. By providing a head start in the race against radiation damage, over the last thirty years it has enabled bright synchrotron light sources to be used to solve countless protein structures at high resolution. Yet a distant cry from physiologically relevant temperatures, cryogenic cooling is not always the answer.

Recent advances in X-ray crystallography have led to the advent of serial crystallography, in which data is collected from a stream of many small crystals in random orientation and merged together. As each crystal is only measured once, radiation damage at synchrotrons is dramatically reduced, enabling room temperature measurements. In addition, it enabled the development of time-resolved structural studies, resulting in so-called ‘molecular movies’, which is instrumental for our understanding of protein dynamics.

In serial crystallography, thousands of protein crystals are continuously delivered to the X-ray beam, requiring a reliable method for the generation of large quantities of small, well diffracting proteins. Depending on the protein, this may pose a major challenge.

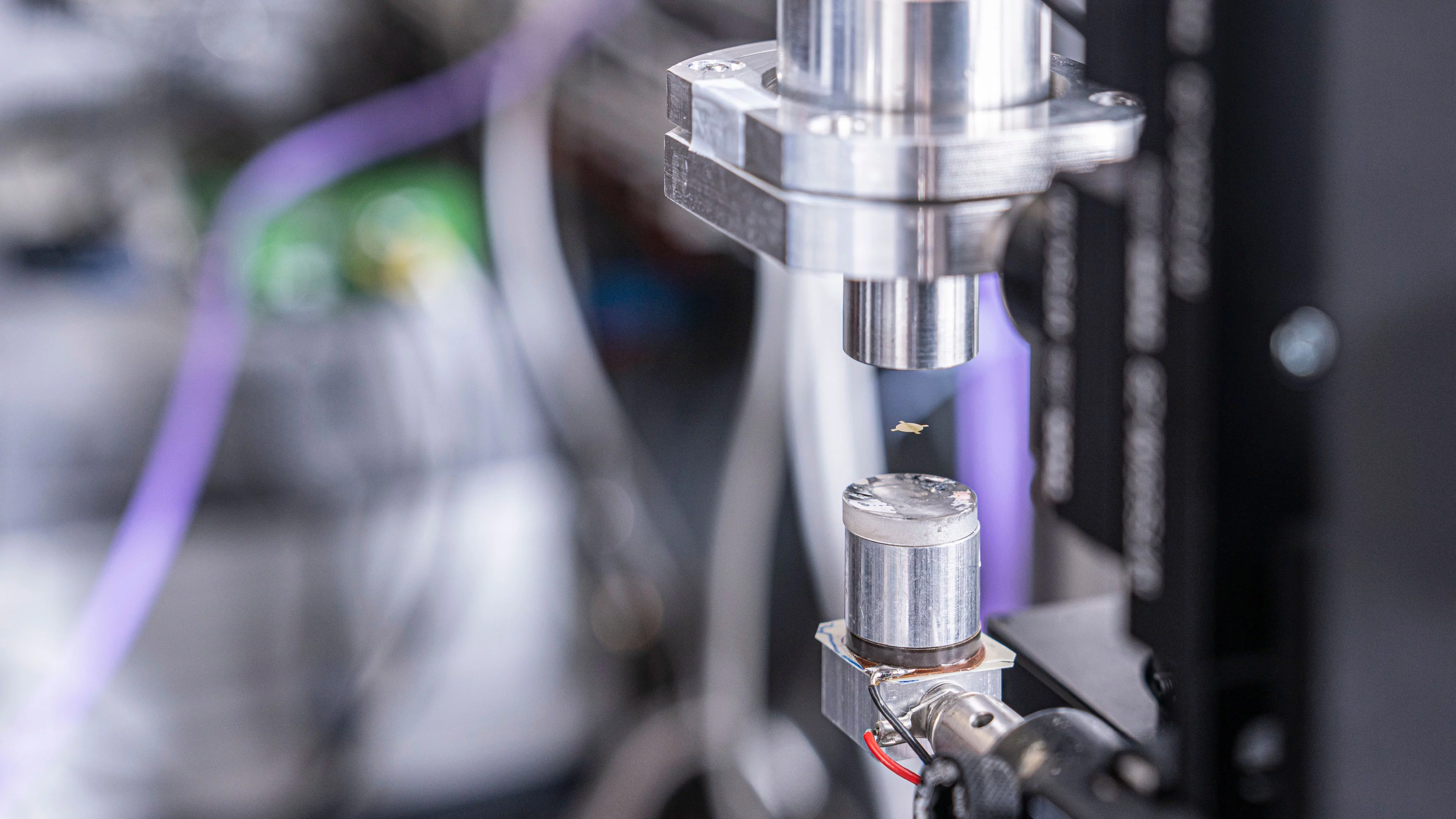

At the Swiss Light Source (SLS), a complementary, static, sample delivery system is on the menu that enables room temperature measurements of a single crystal: acoustic levitation. Using ultrasound, crystals are presented to the beam within a hovering liquid droplet. The sound waves cause the liquid within the droplet to circulate and the crystal to spin very rapidly: much more rapidly than with the ‘goniometers’ that usually rotate crystals. If this rapid spinning is met with a sufficiently high frame rate detector – such as the EIGER X 1M pixel X-ray detector (from PSI spin-off, Dectris AG) at the macromolecular crystallography XO6SA beamline - data can be collected from all crystal angles in just a few seconds. Therefore, a protein can be analysed very quickly at room temperature before the X-rays destroy it.

Towards a fully automated pipeline for room temperature protein crystallography

A major appeal of room temperature crystallography using acoustic levitation is to do with throughput. Throughput is a big deal in structure-based drug design, where the 3D geometry of how a drug candidate binds to a target protein drives drug development. During this iterative process, ideally libraries of thousands of drug-protein complexes are screened by X-ray crystallography. Although a combination of highly brilliant synchrotron light sources and fast frame-rate detectors now enables data collection in well under a minute, the pipeline is bogged down by painstaking manual processes related to cryogenic cooling of crystals.

To develop the acoustic levitation platform, PSI researchers led by Soichiro Tsujino and Takashi Tomizaki are collaborating with PSI spin-off, leadXpro AG, which specialises in structure based drug discovery on membrane proteins, as part of a project funded by Innosuisse. “We are interested in developing automated technologies for sample delivery at synchrotrons and free-electron lasers as well as investigating protein dynamics by time resolved structure studies to design new drug candidates for medicines,” explains Michael Hennig, CEO at leadXpro.

Of course, throughput gains offered by acoustic levitation will be in vain if getting the proteins in position is laborious. Thus, the researchers strive to create a fully automated pipeline for levitation-based room temperature protein crystallography. To this end, developments are underway in automated sample harvesting and delivery of samples grown on the films as well as the invention of on-demand sample ejection and capture by the acoustic levitator.

A unique opportunity to study mixing

The static room temperature set-up that the acoustic levitator offers opens the door to an interesting and little-explored avenue: mixing. Using acoustic technology, the researchers are able to bring a second droplet together with the droplet containing the proteins crystal. This second droplet would contain an external trigger - a drug molecule, or a solution at a different pH, for example. Taking snapshots with the X-ray beam over time, the dynamics of the protein crystal could be studied in response to this external trigger.

“This is a really interesting timescale, which is complementary to that of serial femtosecond crystallography done at Free Electron Lasers,” explains Michal Kepa, who focused on development of the levitator during his PSI Marie Curie fellowship. “Most time-resolved studies of proteins, have been done by laser activation. However, light activated processes, although very important, make up only a small proportion of all natural biological processes. Indeed, up to 98 percent are not light activated but involve enzymatic reactions, which happen much slower and would require a means for mixing”.

Getting the membrane proteins on board

The latest development, which could be inspired by the hoverboards of ‘Back to the Future’, aims to bring on board one of the most interesting and but also technically most challenging groups of proteins: Membrane proteins, the cell’s point of contact with the outside world, play pivotal physiological roles and are important targets for drug discovery. They include the so-called G-protein coupled receptors (GPCRs), which mediate a diverse range of cell signalling pathways and are the target of around 35 percent of approved pharmaceuticals.

Yet, outside of cell membranes, which consist primarily of fatty acid derivates, these proteins are delicate, unstable and notoriously difficult to crystallise. One technique is to crystallise them in a viscous medium known as lipidic cubic phase (LCP). Unfortunately, highly viscous samples such as these cannot be loaded in droplets onto the acoustic levitator; thus this important class of proteins were previously excluded from the platform.

In a recent publication in Scientific Reports, co-authored by the PSI and leadXpro team, samples are dispensed onto meticulously designed thin polymer films. In contrast to the levitating droplet method, in which the crystal rotates because of acoustic streaming, here the mechanism of rotation is different: the film itself rotates as a result of torque generated by coupling of acoustic pressure with tiny asymmetries in the film.

“When applied to room temperature protein crystallography, perfecting rotation is key,” explains physicist Tsujino. “The trouble with the thin films is that they’re not spherical, and without a careful design this anisotropy can cause very fast and out of control rotation. To start with, they kept whizzing off the levitator”. The optimised design resembles a circular saw: short side blades stabilise the rotation.

Hoverboards under control, the researchers put the thin films to the test to perform X-ray crystallography of known proteins prepared in the viscous LCP medium. They could successfully solve the crystal structure of a membrane protein: the microbial light-driven sodium ion pump K. eikastus rhodopsin 2.

Even when crystallised in LCP, or using other tricks of the trade, membrane proteins often fail to form large, well diffracting crystals. Here, the SLS 2.0 upgrade may be key. The researchers intend, with the high intensity beam planned for the upgrade, to analyse microcrystals on levitated films – a form of serial crystallography. The highly flexible levitator, already available to users in a pilot project at the SLS, will become a permanent feature at SLS 2.0. Easily fitted or removed, it will be part of a new versatile endstation for serial protein crystallography, sitting alongside other sample delivery options.

Text: Paul Scherrer Institute/Miriam Arrell

Contact

Dr. Soichiro Tsujino

Senior Scientist,

Paul Scherrer Institute, Forschungsstrasse 111, 5232 Villigen PSI, Switzerland

Telephone: +41 56 310 23 04

Email: soichiro.tsujino@psi.ch

Original Publication

Acoustic levitation and rotation of thin films and their application for room temperature protein crystallography

Michal. W. Kepa, Takashi Tomizaki, Yohei Sato, Dmitry Ozerov, Hiroshi Sekiguchi, Nobuhiro Yasuda, Koki Aoyama, Petr Skopintsev, Jörg Standfuss, Robert Cheng, Michael Hennig & Soichiro Tsujino

Scientific Reports (2022)

DOI: 10.1038/s41598-022-09167-z

Further Information

- Acoustic levitation diffractometer | LNB | Paul Scherrer Institut (PSI)

- Experiment in a hovering droplet | Our Research | Paul Scherrer Institut (PSI)

- leadXpro – Unlocking membrane proteins for drug discovery

Funding

This research was funded by Innosuisse – the Swiss Innovation Agency.

Copyright

PSI provides image and/or video material free of charge for media coverage of the content of the above text. Use of this material for other purposes is not permitted. This also includes the transfer of the image and video material into databases as well as sale by third parties.