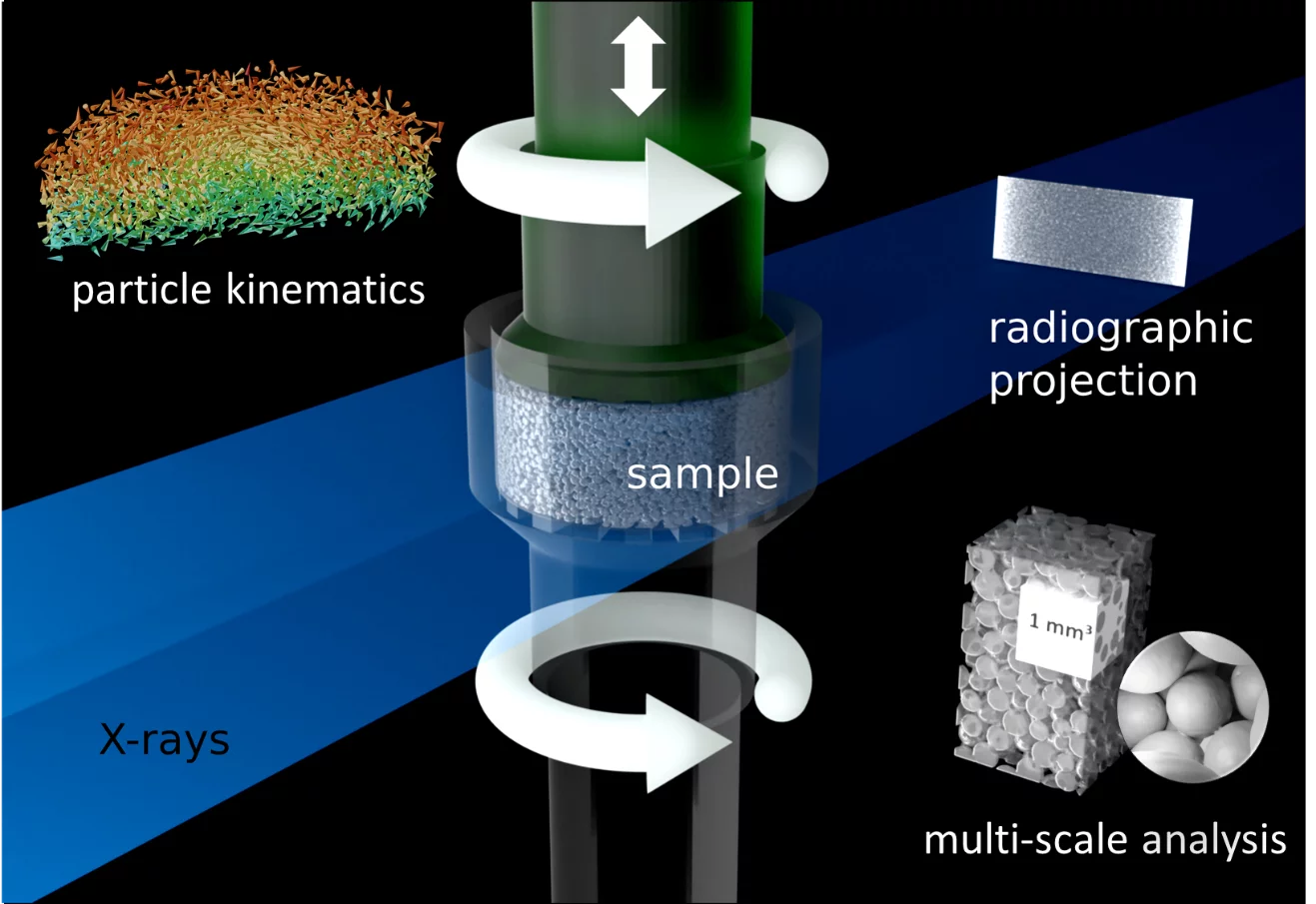

Most materials in nature or industry do not behave like ideal solids (Hookean) or fluids (Newtonian), and their constitutive equations are not obvious ab initio. Their multi-scale structure determines a response to strain (- rate) or stress. Although synchrotron X-ray tomography allows capturing structural rearrangement over several length scales at ever faster acquisition rates [1, 2] a platform for rheological surveys capable of inducing different types of flows or deformation in combination with continuous-motion test protocols is still missing. We developed tomo-rheoscopy at TOMCAT, a full-volume time-resolved approach to elucidate microstructural transients and dynamics in different rheometric flow scenarios (Fig.1) and acquisition modes.

Granular material is found in many different scientific and industrial domains and represents here a great working example. It is well suited for tomographic microscopy, and its rheological behavior poses many open questions [3-5]. Our method allows the continuous imaging of individual grain kinematics (Fig.2) and acquires synchronously relevant macroscopic forces and strains for its mechanical characterization.

Furthermore, in this project, we extend the range of materials (Fig.3) and test protocols suitable for Tomo-Rheoscopy, integrating it as a universal platform for material testing on the TOMCAT beamline, and make it available to our broad user community.

References

- Mokso, R. et al. GigaFRoST: the gigabit fast readout system for tomography. Journal of Synchrotron Radiation 24, 1250–1259 (2017).

- García-Moreno, F. et al. Tomoscopy: Time-Resolved Tomography for Dynamic Processes in Materials. Advanced Materials 33, 2104659 (2021).

- Andreotti, B., Forterre, Y., & Pouliquen, O. (2013). Granular Media: Between Fluid and Solid. Cambridge, UK, Cambridge University Press, 469 pp.

- Viggiani, G., & Tengattini, A. (2019). Recent developments in laboratory testing of geomaterials with emphasis on imaging. Proceedings of the XVII ECSMGE-2019.

- Baker, J., Guillard, F., Marks, B., & Einav, I. (2018). X-ray rheography uncovers planar granular flows despite non-planar walls. Nature Communications, 9(1), 1–9.

Funding

SNF R'Equip 2021 and PSI

Contact

- Dr. Christian Schlepütz, christian.schlepuetz@psi.ch

- Dr. Stefan Gstöhl, stefan.gstoehl@psi.ch