Additive manufacturing (AM) or “3D printing” of metals, which builds structure layer by layer, has revolutionized the production of intricate 3D designs. Among its techniques, laser powder bed fusion (PBF-LB) excels in creating metallic parts with intricate designs and high precision. This process can combine different metals into innovative multi-material components with tailored properties, with regards to e.g., strength and thermal conductivity, surpassing the capabilities of single-material designs.

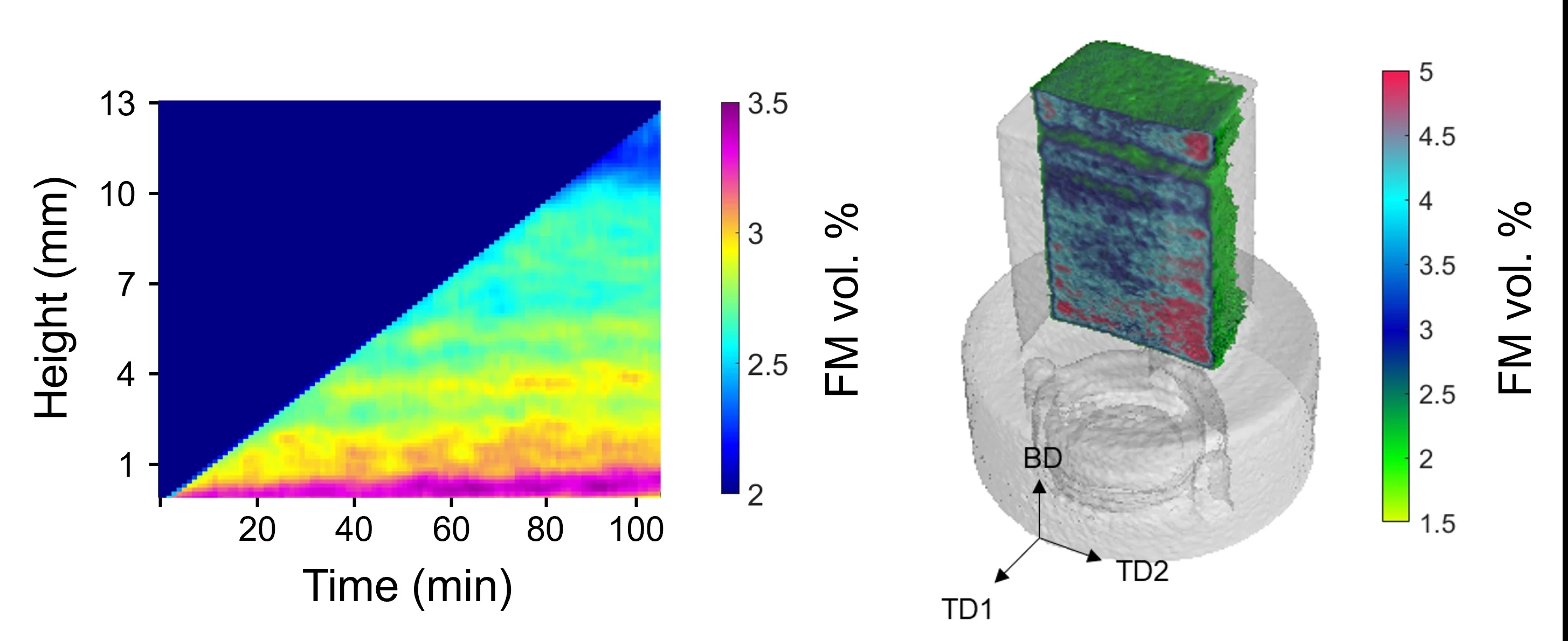

However, understanding and optimizing the constitution/conformation of materials through this complex process is a significant challenge. In our study, we introduce a custom-designed laser powder bed additive manufacturing machine that can be operated in neutron instruments. The high penetration power of neutrons then enables to track the material evolution during fabrication.

Neutron imaging revealed how the complex thermal cycling during the process affects the development and distribution of material phases in multi-material parts made of stainless steel and Cu-alloy and, thus, answers critical questions on the parameters required to achieve specific microstructures and resulting material properties. The findings in particular highlight the potential of neutron imaging to better understand the AM processes. This will help to optimize and control material properties, advancing the design and performance of AM built components.

Facility: SINQ

Reference: S. Sumarli et al, Virtual and Physical Prototyping 19, e2429132 (2024)

Read full article: here