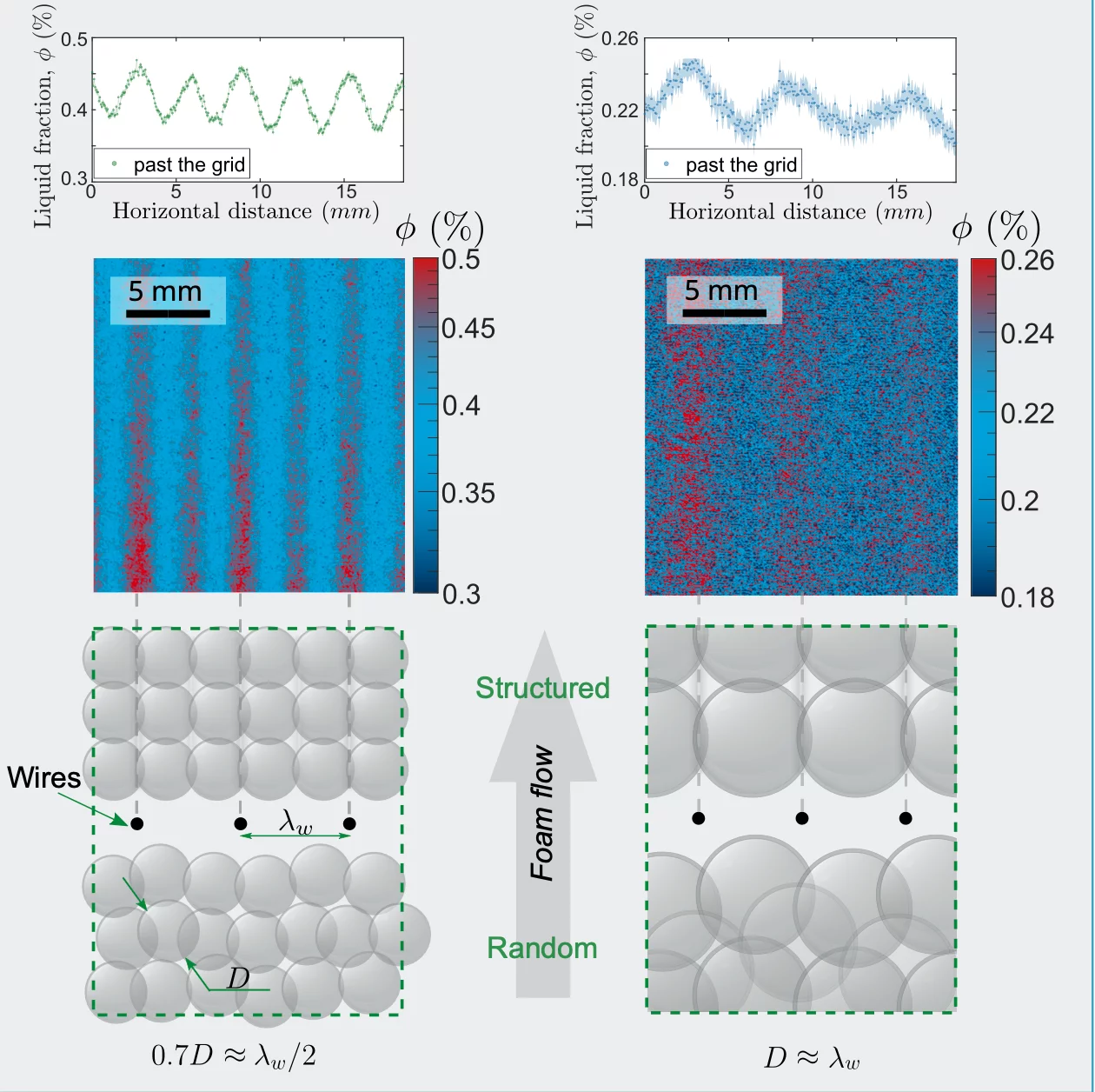

Efficient manufacturing methods could unlock foams with tailored, anisotropic properties. Conventional foam production methods rely on the self-arrangement of bubbles, typically leading to isotropic materials, or involve intricate additive layering processes. This study presents a simple, passive technique to modify the foam structure. A set of thin parallel wires was introduced into the foam flow. Initially, the bubbles are randomly arranged as they rise vertically within a column. Passing through the wire grid alters the bubble arrangement.

Neutron radiography of the flowing foam reveals a distinct change in the structural organization of the bubbles. The resulting structural anisotropy is characterized by alternating layers of high and low liquid fractions. The strength of the pattern is significantly influenced by the relation between bubble size and wire spacing. These findings suggest a potential approach for creating architected materials from liquid foam, offering new possibilities for material design and improved functionality.

Facility: SINQ

Reference: A. Skrypnik et al, Matter 8, 102452 (2025)

Read full article: here