Thin films are nowadays utilized in many applications, ranging from semiconductor devices to optical coatings and are even present in pharmaceuticals (polymers). This wide-spread application of films with thicknesses from atomic monolayers to microns is due to the developments of thin film deposition techniques. Thin films are also important for studies of materials with new and unique properties due to the possibility of tuning their crystallographic and morphological properties. The thin film approach, i.e. the presence of interfaces (to a substrate or the film surface) adds more degrees of freedom for influencing the properties of materials, e.g. by lattice strain or surface functionalization. For these fundamental studies of material properties large research facilities such as synchrotron radiation or neutron spallation sources are one of the keys that the Paul Scherrer Institute (PSI) provides.

News

E-MRS 2025 Spring Meeting Young Researcher Award for Mohammadhossein Montazerian

During its recent spring meeting the European Materials Research Society has awarded the E-MRS Young Researcher Award to Mohammadhossein Montazerian from the LMX laboratory in recognition of his "Outstanding contribution to the Symposium L: Solid state batteries - materials, processing and advanced characterization".

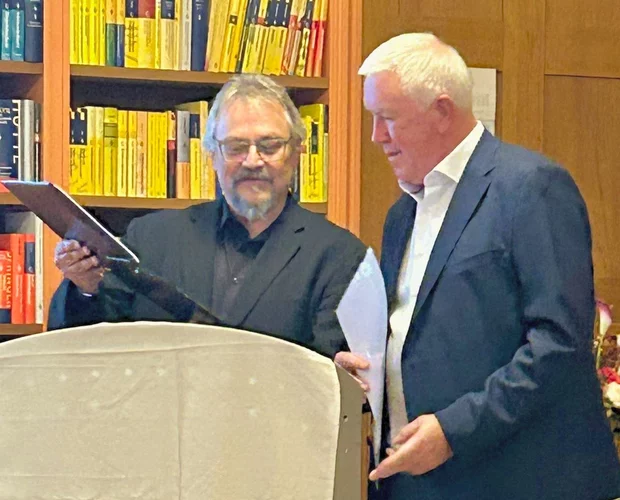

Julius Springer Price 2024

Prof. Thomas Lippert, Editor in Chief at Applied Physics A, awards Prof. Boris Chichkov the 2024 Julius Springer Prize for Applied Physics.

Appointment of Thomas Lippert as new head of the Laboratory for Multiscale Materials Experiments (LMX)

Starting 1. December 2022, Prof. Dr. Dr. Thomas Lippert will be the new head of the Laboratory for Multiscale Materials Experiments (LMX). He follows Prof. Dr. Laura Heyderman, our first laboratory head who successfully formed and established the LMX in the PSI landscape as a Centre of Materials.

Upcoming Seminars

TFI Meeting

Date: Monday 21 July 2025, 16:00

Title: TBA

Speaker: Xiaochun Huang

Room: OFLG/402

TFI Literature Meeting

Date: Monday 28 July 2025, 16:00

Speaker: Mohammadhossein Montazerian & Adil Baiju

Room: OFLG/401

TFI Meeting

Date: Monday 4 August 2025, 16:00

Title: TBA

Guest Speaker: Prof. Dr. Sarbajit Banerjee, Department of Chemistry and Applied Biosciences ETH-Zurich and Head of Laboratory for Battery Science PSI-CEE

Room: OFLA/002

LMX Meeting

Date: Thursday 7 August 2025, 13:00

Title: TBA

Speaker: Tianyue Wang

Room: ODRA/111

TFI Meeting

Date: Monday 11 August 2025, 16:00

Title: TBA

Speakers: Raphael Martin & Thinley Ugyen

Room: OFLGA/401

TFI Meeting

Date: Monday 18 August 2025, 16:00

Title: TBA

Speaker: Timo Piecuch

Room: OFLG/402

TFI Literature Meeting

Date: Monday 25 August 2025, 16:00

Speaker: Christof Schneider & Daniele Pergolesi

Room: OFLG/401

Upcoming Conferences

September 2024

iWOE-30 2024

International Workshop on Oxide Electronics

September 29.-2.October 2024 , Darmstadt, Germany

More Information

August 2024

International Mass Spectrometry Conference 2024

Aug. 17-23, 2024

Melbourne, Australia

More Information will be provided here

Scientific Highlights

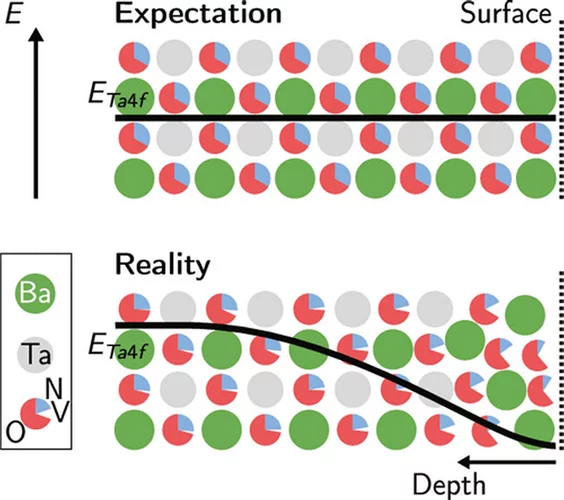

Anionic Disorder and Its Impact on the Surface Electronic Structure of Oxynitride Photoactive Semiconductors

The conversion of solar energy into chemical energy, stored in the form of hydrogen, bears enormous potential as a sustainable fuel for powering emerging technologies. Photoactive oxynitrides are promising materials for splitting water into molecular oxygen and hydrogen. However, one of the issues limiting widespread commercial use of oxynitrides is degradation during operation. While recent studies have shown the loss of nitrogen, its relation to reduced efficiency has not been directly and systematically addressed with experiments. In this study, we demonstrate the impact of the anionic stoichiometry of BaTaOxNy on its electronic structure and functional properties. Through experimental ion scattering, electron microscopy, and photoelectron spectroscopy investigations, we determine the anionic composition ranging from the bulk toward the surface of BaTaOxNy thin films. This further serves as input for band structure computations modeling the substitutional disorder of the anion sites. Combining our experimental and computational approaches, we reveal the depth-dependent elemental composition of oxynitride films, resulting in downward band bending and the loss of semiconducting character toward the surface. Extending beyond idealized systems, we demonstrate the relation between the electronic properties of real oxynitride photoanodes and their performance, providing guidelines for engineering highly efficient photoelectrodes and photocatalysts for clean hydrogen production.

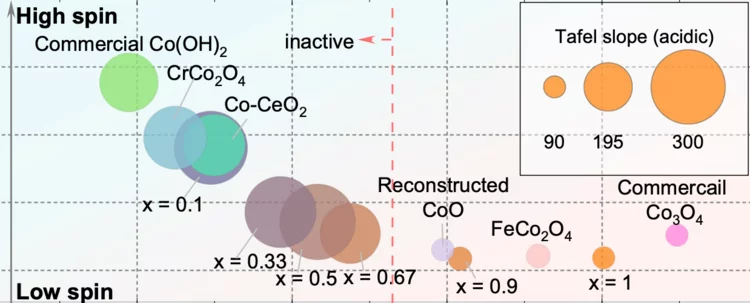

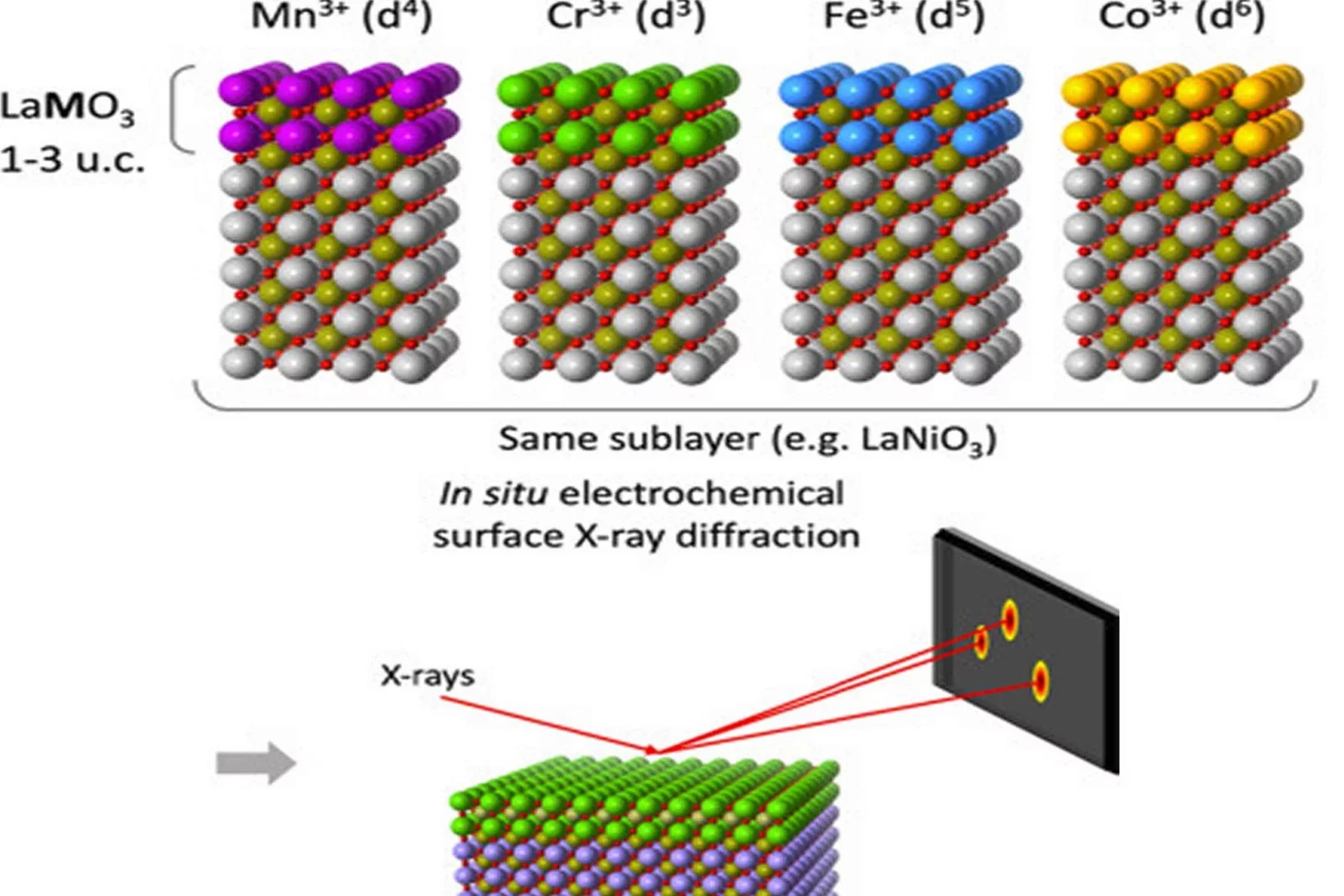

Surface oxidation/spin state determines oxygen evolution reaction activity of cobalt-based catalysts in acidic environment

Co-based catalysts are promising candidates to replace Ir/Ru-based oxides for oxygen evolution reaction (OER) catalysis in an acidic environment. However, both the reaction mechanism and the active species under acidic conditions remain unclear. In this study, by combining surface-sensitive soft X-ray absorption spectroscopy characterization with electrochemical analysis, we discover that the acidic OER activity of Co-based catalysts are determined by their surface oxidation/spin state.

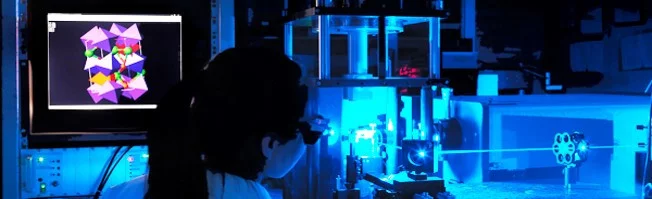

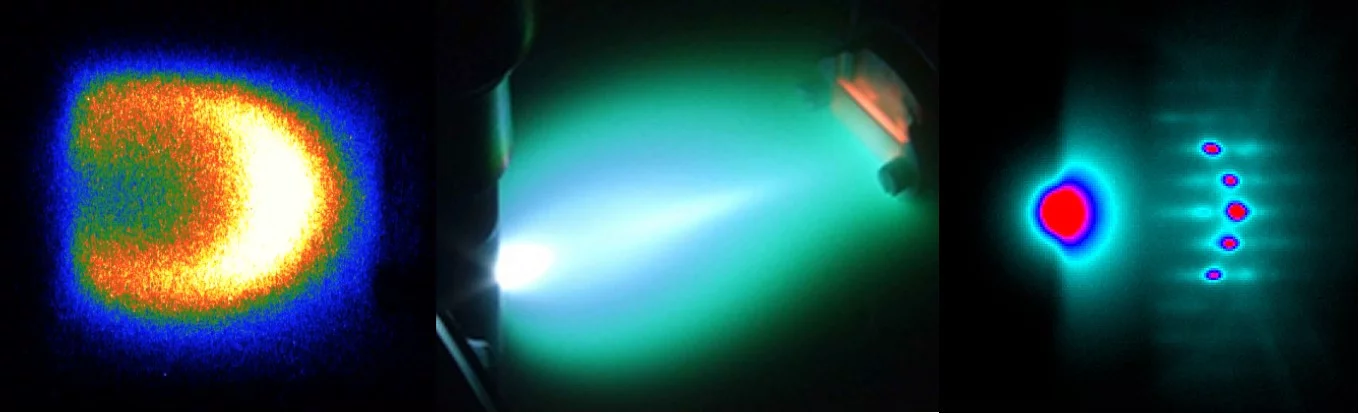

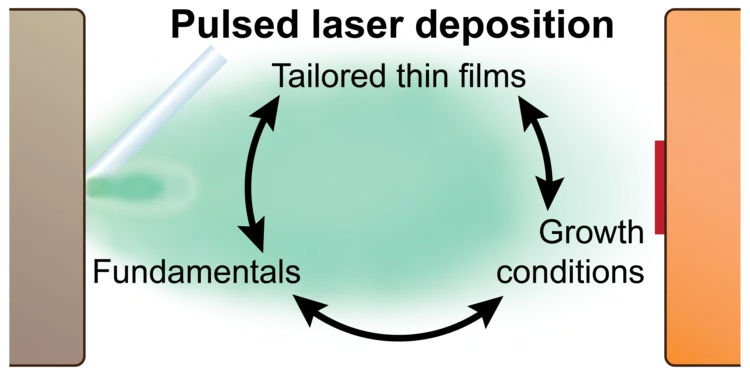

A practical guide to pulsed laser deposition

Nanoscale thin films are widely implemented across a plethora of technological and scientific areas, and form the basis for many advancements that have driven human progress, owing to the high degree of functional tunability based on the chemical composition. Pulsed laser deposition is one of the multiple physical vapour deposition routes to fabricate thin films, employing laser energy to eject material from a target in the form of a plasma ...