The mission of the microXAS beamline project is to operate and advance a versatile hard x-ray microprobe facility for multimodal chemical microscopy and micro-spectroscopy. We strive to enhance spatial resolution, and to develop new or superior chemical contrast modes. Over a large range of length (and time) scales, we apply this comprehensive set of X-ray microbeam analytical techniques to scientific challenges in the broader scope of reactive transport in porous media: From virus metabolite distribution in single cells, over the variability of catalytic reactivity in single crystal catalysts, to reactive contaminant transport phenomena in heterogeneous natural porous media.

The scientific and engineering activities directly related to the instrumentation of the microXAS beamline facility are complemented by a vivid in-house science program. These research activities link to the development of an advanced understanding of macroscopic reactivity and dynamics of complex systems based on the micro/nanoscopic physical and chemical. The focus subject corresponds to enlightening our understanding of environmental chemical processes – including their link to physics and biology. Special emphasis is devoted to the characterization of chemical reactions occurring at solid-liquid interfaces in undisturbed surface and subsurface environments.

Scientific highlights

Additive manufacturing of alloys with programmable microstructure and properties

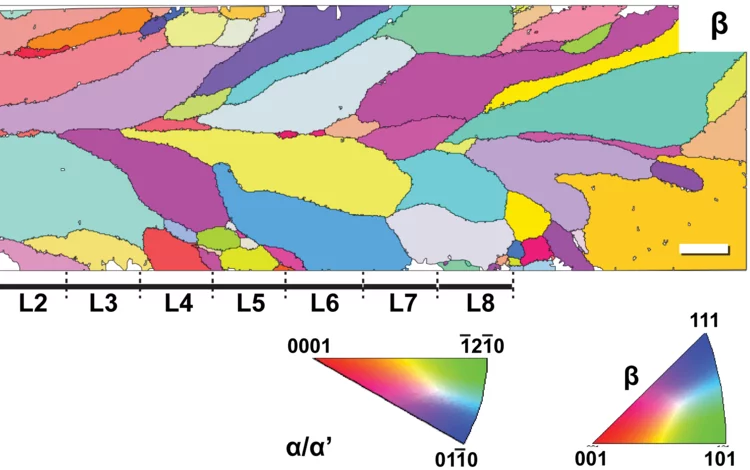

Using laser powder bed fusion (LPBF) technology, we devise special processing strategies to ‘program’ the thermal stability of the as-printed alloy, such that it is possible to decide, a priori, how the material’s microstructure will evolve upon heat treatment

Thermal cycling during 3D laser printing

High-speed in situ X-ray diffraction is used to measure temperature profiles and cooling rates during 3D printing of a a Ti-6Al-4V single-track wall.

Thermal and phase evolution during laser powder bed fusion of Al-Sc-Zr elemental powder blends

The reaction of elemental scandium and zirconium powders with liquid aluminum is observed directly via operando X-ray diffraction during laser 3D printing. This work demonstrates that elemental blends can be used to create fine-grained crack-free Al-alloys and highlights the importance of feature size.