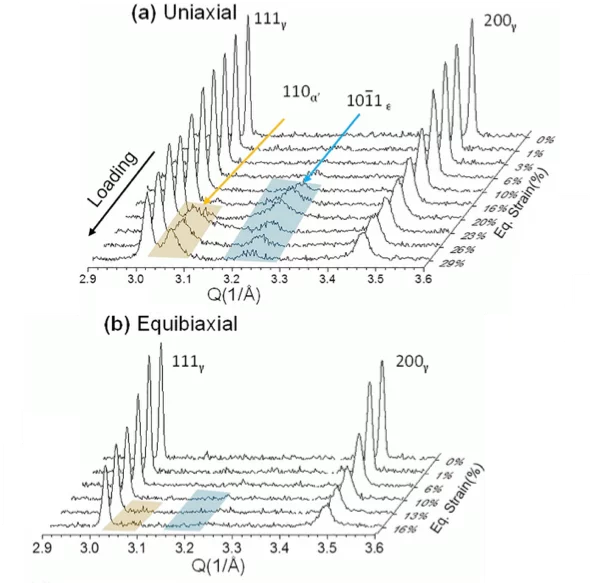

Most of the existing studies, implement kinetic laws where the triaxiality factor, Σ, defined as the ratio of the hydrostatic stress to the von Misses equivalent stress, is used as a fit parameter affecting the kinetics of the martensitic transformation. However, our investigations using the novel biaxial rig at POLDI, a discrepancy has been observed whether the transformation is a monotonic function of stress triaxiality, as shown in Fig. 1.

Using the novel biaxial machine at POLDI, it was possible to study the transformation induced plasticity (TRIP) effect under equiaxial or non-proportional biaxial loading states. It was possible to unveil the effect of loading state on the TRIP behavior in different grades of technologically important steels. In specific, the effect of uniaxial/multiaxial loading on the TRIP effect was studied in situ with neutron diffraction, in two metastable austenitic stainless steels with different stacking fault energy (SFE) [1,2]. Moreover, the effect of different stress triaxiality factor on the TRIP effect was investigated experimentally and modelled on a low-alloyed Quenched and Partitioning (Q&P) TRIP-Bainitic Ferrite steel with dispersed metastable austenite particles [3].

These studies indicate that the stress triaxiality, which is associated with the growth mechanism of martensite, cannot solely account for the differences in the transformation kinetics between different loading states, but the loading state plays a key role on the nucleation mechanisms in these materials [4]. The nucleation mechanisms of martensite in these steels, is moreover, strongly dependent on the stacking fault energy of the material.

Publications

1. Polatidis E, Šmíd M, Hsu W-N, Kubenova M, Capek J, Panzner T, et al. The interplay between deformation mechanisms in austenitic 304 steel during uniaxial and equibiaxial loading Materials Science and Engineering A: Structural Materials: Properties, Microstructure and Processing. 2019; 764: 138222 (7 pp.). https://doi.org/10.1016/j.msea.2019.138222

2. Polatidis E, Hsu WN, Šmíd M, Panzner T, Chakrabarty S, Pant P, et al. Suppressed martensitic transformation under biaxial loading in low stacking fault energy metastable austenitic steels Scripta Materialia. 2018; 147: 27-32. https://doi.org/10.1016/j.scriptamat.2017.12.026

3. Polatidis E, Haidemenopoulos GN, Krizan D, Aravas N, Panzner T, Šmíd M, et al. The effect of stress triaxiality on the phase transformation in transformation induced plasticity steels: experimental investigation and modelling the transformation kinetics Materials Science and Engineering A: Structural Materials: Properties, Microstructure and Processing. 2021; 800: 140321 (10 pp.) https://doi.org/10.1016/j.msea.2020.140321

4. Zecevic M, Upadhyay MV, Polatidis E, Panzner T, Van Swygenhoven H, Knezevic M A crystallographic extension to the Olson-Cohen model for predicting strain path dependence of martensitic transformation Acta Materialia. 2019; 166: 386-401. https://doi.org/10.1016/j.actamat.2018.12.060

Collaboration

- Prof. H. Van Swygenhoven EPFL/PSI

- Prof. M. Knezevic University of New Hampshire

- Prof. G. Haidemenopoulos University of Thessaly

- Prof. M. Upadhyay Ecole Polytechnique

Funding

- H. Van Swygenhoven - ERC advanced Grant MULTIAX (339245)

Associated junior researchers

- Dr. J. Capek

Contact

- Dr. Efthymios Polatidis

- Dr. Jan Capek