Diffraction contrast neutron imaging [1] often referred to as Bragg edge imaging, is based on the wavelength dependent impact of neutron diffraction at crystal lattice planes on the transmission. A Bragg edge can be observed in the attenuation spectrum at a wavelength where for a specific crystal lattice parameter dhkl the Bragg condition reduces to λ=2d as the diffraction angle reaches θ=90°. Thus, beyond such wavelength no Bragg scattering can take place this lattice plane family anymore and the transmission correspondingly increases sharply. This also implies, that for powder-like polycrystalline materials the Bragg edges directly measure the lattice spacings and allow identifying crystalline phases. The exact position of edges carries also information on lattice strains and the overall pattern can be analysed for other microstructural features such as grain size and texture variations. For single- or large grained oligo-crystals on the other hand diffraction contrast allows to index and map grains or orientation distributions [2].

Correspondingly, Bragg edge imaging can be applied to crystalline materials, given they provide a sufficient coherent scattering cross section, like many metallic structural and engineering materials. Therefore we offer all these techniques and apply them in particular in engineering materials research, including additive manufacturing, but also in cultural heritage and for other relevant fields.

As diffraction contrast, Bragg edge, imaging is based on wavelength resolved imaging, it requires intrumentational means such as monochromators, velocity selectors or a pulsed beam for time-of-flight (ToF) wavelength resolution. The latter enables probing a significant range of wavelengths simultaneously. Most notable we have developed a technique, based on a multi-slit chopper, for highly efficient ToF imaging at continuous sources like SINQ [3]. Therefore we can provide all available techniques for wavelength resolved diffraction contrast imaging. All techniques are available at ICON, ToF and a double crystal monochromator at BOA (a velocity selector shall follow soon. For thermal neutrons we offer ToF diffraction contrast neutron imaging at POLDI.

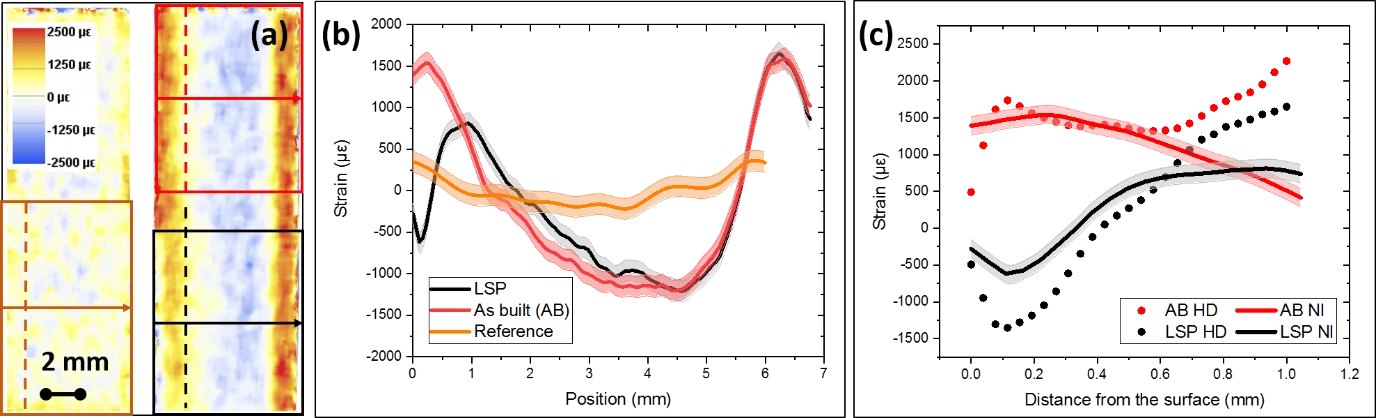

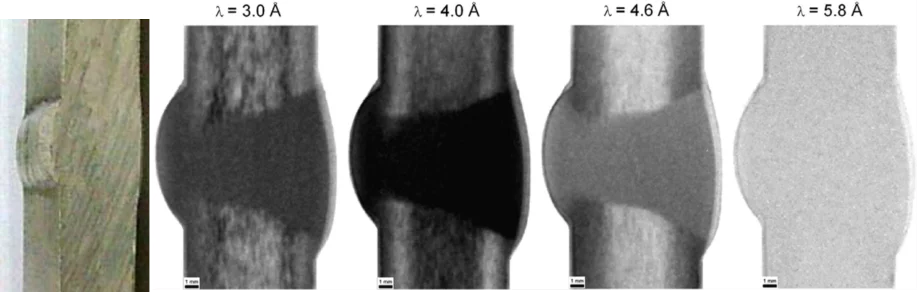

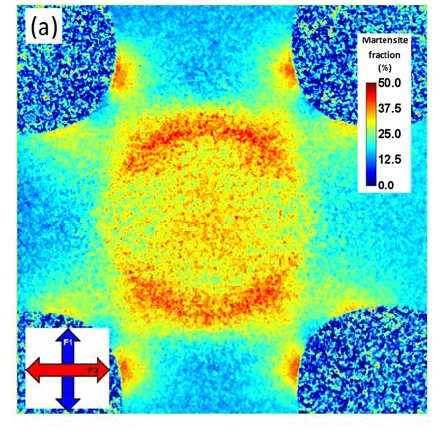

An examples of Bragg edge imaging for analyzing stress fields is given in Fig. 1, where the investigation of the effect of laser shock peening (LSP) on a steel sample built by laser powder bed fusion (LBPF) additive manufacturing (AM) and a corresponding reference display the potential of the method [4], [5]. Crystalline texture and grain size effects are visualized in Fig. 2 showing a weld of cold rolled Al plates [6] and the martensite distribution in a bi-axial load sample of austenitic trip steel following deformation is provided in Fig. 3 [7].

Publications

- R. Woracek, J. Santisteban, A. Fedrigo, y M. Strobl, «Diffraction in neutron imaging—A review», Nuclear Instruments and Methods in Physics Research Section A: Accelerators, Spectrometers, Detectors and Associated Equipment, vol. 878, pp. 141-158, ene. 2018

- A. Cereser et al., «Time-of-Flight Three Dimensional Neutron Diffraction in Transmission Mode for Mapping Crystal Grain Structures», Sci Rep, vol. 7, n.o 1, p. 9561, dic. 2017.

- M. Busi et al., «Frame overlap Bragg edge imaging», Scientific Reports, vol. 10, n.o 1, Art. n.o 1, sep. 2020

- M. Busi et al., «A parametric neutron Bragg edge imaging study of additively manufactured samples treated by laser shock peening», Sci Rep, vol. 11, n.o 1, p. 14919, dic. 2021

- M. Morgano et al., «Investigation of the effect of Laser Shock Peening in Additively Manufactured samples through Bragg Edge Neutron Imaging», Additive Manufacturing, vol. 34, p. 101201, ago. 2020

- E. H. Lehmann, S. Peetermans, L. Josic, H. Leber, y H. van Swygenhoven, «Energy-selective neutron imaging with high spatial resolution and its impact on the study of crystalline-structured materials», Nuclear Instruments and Methods in Physics Research Section A: Accelerators, Spectrometers, Detectors and Associated Equipment, vol. 735, pp. 102-109, ene. 2014,

- E. Polatidis et al., «Neutron Diffraction and Diffraction Contrast Imaging for Mapping the TRIP Effect under Load Path Change», Materials, vol. 13, n.o 6, Art. n.o 6, ene. 2020.