Investigating the micro- and nanostructure of polymer materials have been of interest in recent decades since it defines the functionality of the material. Understanding the structure is key to optimize material usage and to further increase the quality of the product.

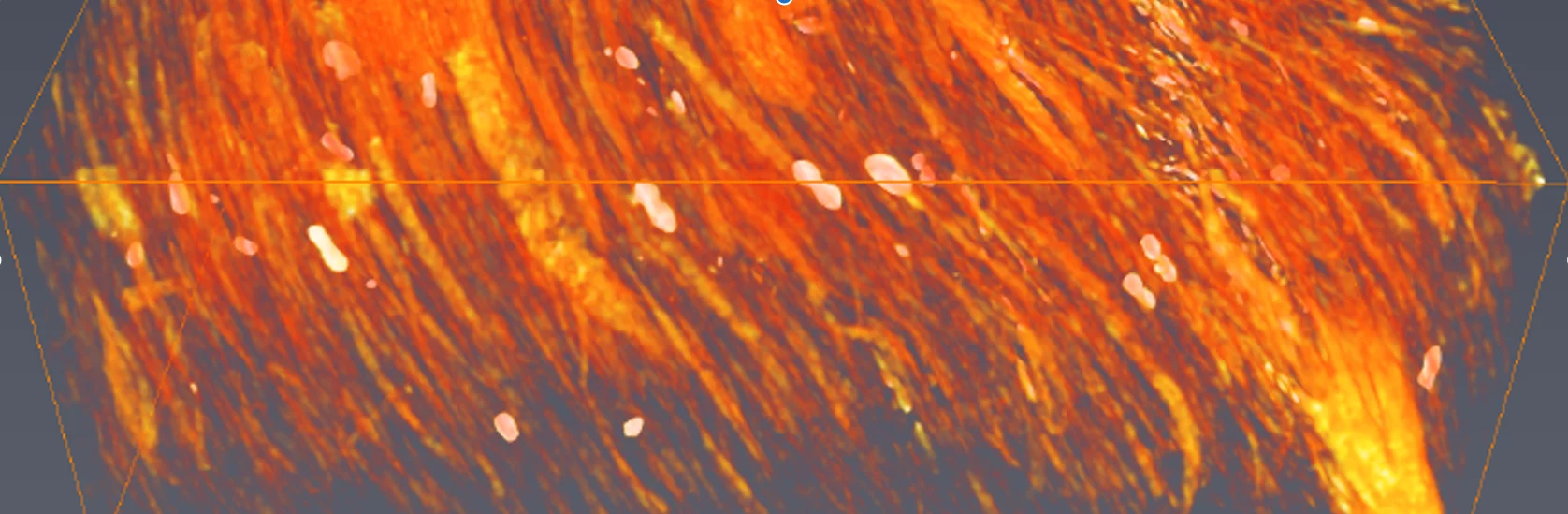

We are using a combination of different X-ray techniques to investigate the polymer material at different length scales. Small- and wide-angle X-ray scattering (SAXS/WAXS) in scanning mode (e.g. at cSAXS) allows to probe the variation of structures formed in semi-crystalline materials, such as sperhulites, elongated spherulites or the highly anisotropic shish-kebab structure. Scanning transmission X-ray microscopy (STXM) with X-ray near-edge absorption (XANES) contrast (e.g. at Pollux) allows to study chemical contrast with very high resolution. Ptychographic tomography allows for 3D structure with resolution below 100 nm, and for sensitive polymer material the measurement under cryo-condition using OMNY is beneficial.

Structure and mechanics of injection-molded thermoplastics

The development in industrial packaging strives to use virtual simulations instead of try-and-error testing to further improve their materials and test new shapes and materials. However, in order to predict mechanical properties with improved accuracy, the detailed material structure need to be included into the simulations. Polymers are often anisotropic materials which properties are highly effected by processing conditions and can therefore be hard to predict. In an industrial collaboration with Tetra Pak® we are using SAXS imaging to study the structure of polyethylene with varying processing conditions. With the proposed structure, we can explain the anisotropic mechanical properties observed in the material, which shows its potential to be used in combination with simulation tools for improved virtual product development. This project is conducted at the Chalmers University of Technology in Gothenburg, Sweden.

Björn, L., Persson Jutemar, E., Melhado Mazza, R., Andreasson, E., Linell, F., Guizar-Sicairos, M., & Liebi, M*.

"Process-Induced Structures of Injection-Molded High-Density Polyethylene─Combining X-ray Scattering and Finite Element Modeling."

ACS Appl. Polym. Mater. 2024., 6, 4852-4864,DOI: 10.1021/acsapm.4c00581

Björn, L., Melhado Mazza, R., Andreasson, E., Linell, F., Lutz-Bueno, V., Guizar-Sicairos, M., Jutemar, E., Liebi, M.*

"Scanning Small-angle X-ray Scattering of Injection Molded Polymers: Anisotropic Structure and Mechanical Properties of Low Density Polyethylene."

Applied Polymer Materials, 2023 5, 6429-6440, DOI: 10.1021/acsapm.3c01007

Lignocellulose based thermoplastics

Within the Swedish VINNOVA competence centre FibRe which is a research consortium between academia (Chalmers University of Technology and KTH Royal Institute of Technology together) industry and public organization partners, we are responsible for the use of X-ray methods for the characterization of lignocellulose based thermoplastics. In particular we are interested in characterizing local chemical modification introduced to make the material thermoplastic using STXM. This project is conducted at the Chalmers University of Technology in Gothenburg, Sweden.

Pharmaceutical Formulations

Pharmaceutical formulations can be utilized as a method for controlled release, for improving dissolution properties and to enhance the bioavailability of an active substance. A key issue to understand and design the functional mechanism of these formulations is to understand its structure and morphology. We are using SAXS/WAXS imaging, ptychographic tomography and STXM to investigate the structure from the micro to nanoscale and to relate the functional properties of the compound to its morphology. This project is conducted at the Chalmers University of Technology in Gothenburg, Sweden.

Olsson, M., Storm, R., Björn, L., Lilja, V., Krupnik, L., Chen, Y., Naidjonoka, P., Diaz, A., Holler, M., Watts, B., Larsson, A., Liebi, M.*, & Matic, A.*

"Phase-separated polymer blends for controlled drug delivery by tuning morphology."

Commun Mater,2024 5(1), 231. DOI:10.1038/s43246-024-00678-y

Olsson, M., Govender, R., Diaz, A., Holler, M., Menzel, A., Abrahmsén-Alami, S., Sadd, M., Larsson, A., Matic, A.*, & Liebi, M.*

"Multiscale X-ray imaging and characterisation of pharmaceutical dosage forms."

International Journal of Pharmaceutics, 123200, 2023. DOI: 10.1016/j.ijpharm.2023.123200

Real-time characterization of anisotropic carbon-based technological fibres, films and composites

This project is embedded within the European Marie Skłodowska-Curie Innovative Training Network “RELIANCE“, which aims to develop novel in-line structure measurement techniques to ultimately enable control of the composite manufacturing processes. In this project, Small-Angle X-ray Scattering tensor tomography (SASTT) is employed as an effective method to analyse the composite hierarchical structure, particularly for obtaining information on the alignment and density of carbon-fibre within the polymer matrix. This will serve not only as reference for the new methods to be developed within the RELIANCE network but will be used to study structure-property-processing correlations for these type of composite materials.