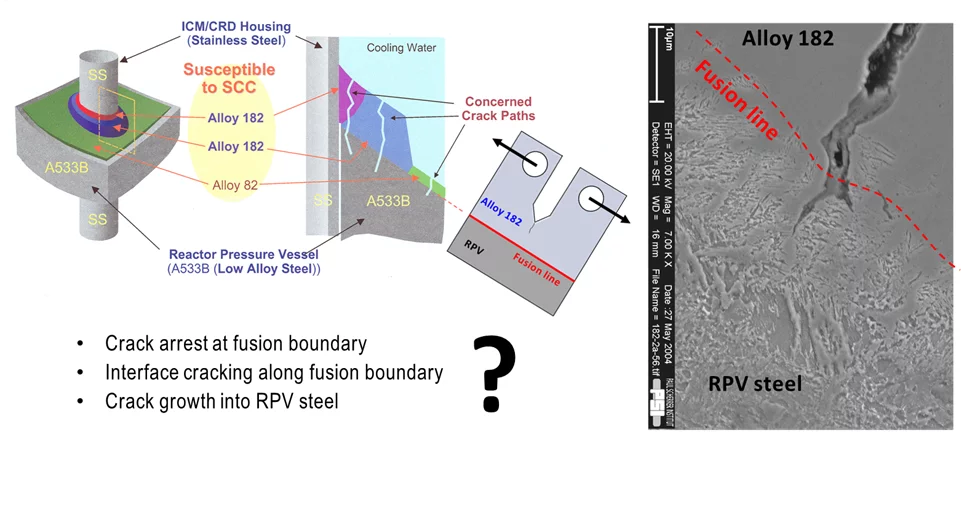

The reactor pressure vessel (RPV) is the most critical component of light water reactors with regard to plant safety and lifetime. The Nickel-base Alloy 182 is widely used as a weld filler and attachment pad metal to join the low-alloy steel RPV and RPV nozzles to both wrought nickel-base alloys and austenitic stainless steel components (piping, reactor internals) in light water reactors by manual shielded metal arc welding. The recent stress corrosion cracking (SCC) in Alloy 182 in RPV nozzles, reactor internal attachment or penetrations dissimilar metal welds in boiling water reactors (BWRs) represent a serious potential safety concern (Figure 1). [1]

The Alloy 182 weld metal is very prone to SCC and cracks tend to grow towards the RPV due to weld microstructure and residual stress profiles in these welds. Such SCC cracks thus might grow into the adjacent RPV, although the SCC was confined to the weld metal and none of the SCC cracks significantly penetrated the adjacent RPV base material in field cracking incidents so far. This is consistent with the very high SCC resistance of the RPV steel. Even after post-weld heat treatment, these highly constrained welds reveal high residual stresses resulting in a high mechanical driving force for SCC cracks that are reaching the fusion boundary region between the weld metal and RPV steel. There is thus a concern that such cracks could grow into the RPV in oxidizing BWR normal water chemistry (NWC) environment, in particular in high-sulphur RPV steels (older plants) or in case of chloride contamination of the coolant or weld repairs [1-3]. It is thus crucial to know, under which conditions these cracks could grow into the RPV. Furthermore, validated SCC crack growth disposition curves for the RPV steels are needed for flaw tolerance and integrity assessments and verification of inspection intervals of periodic in-service inspection and to demonstrate sufficient safety margins. [1]

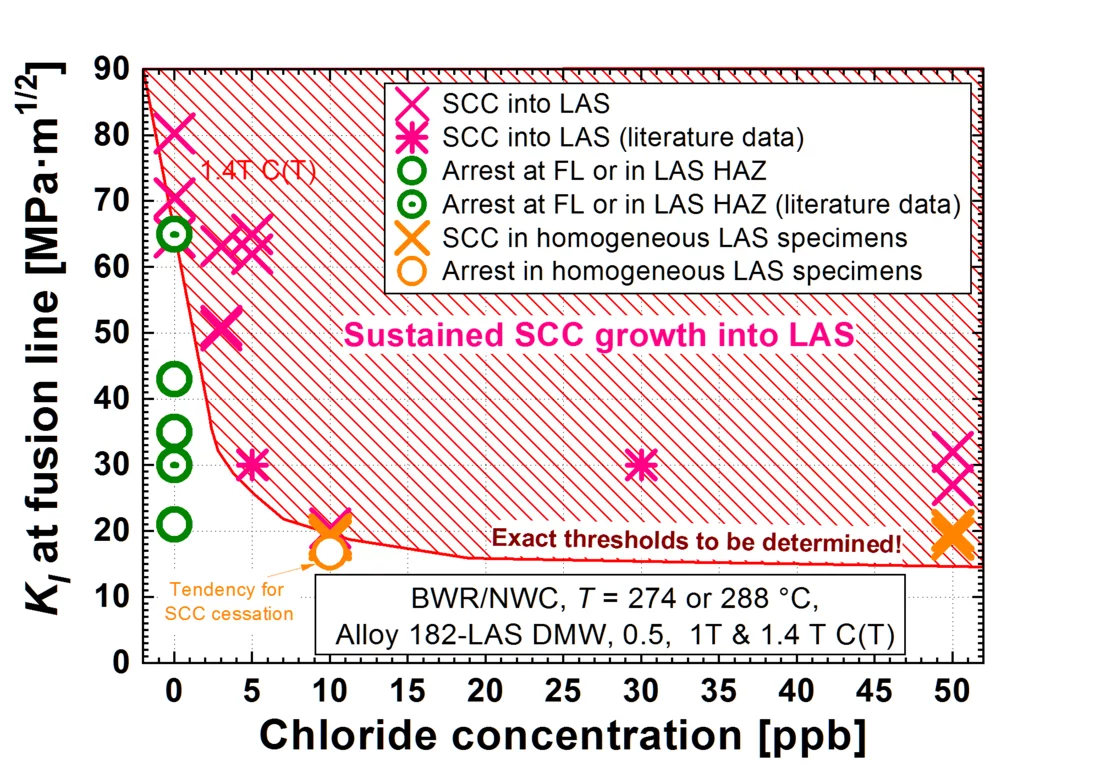

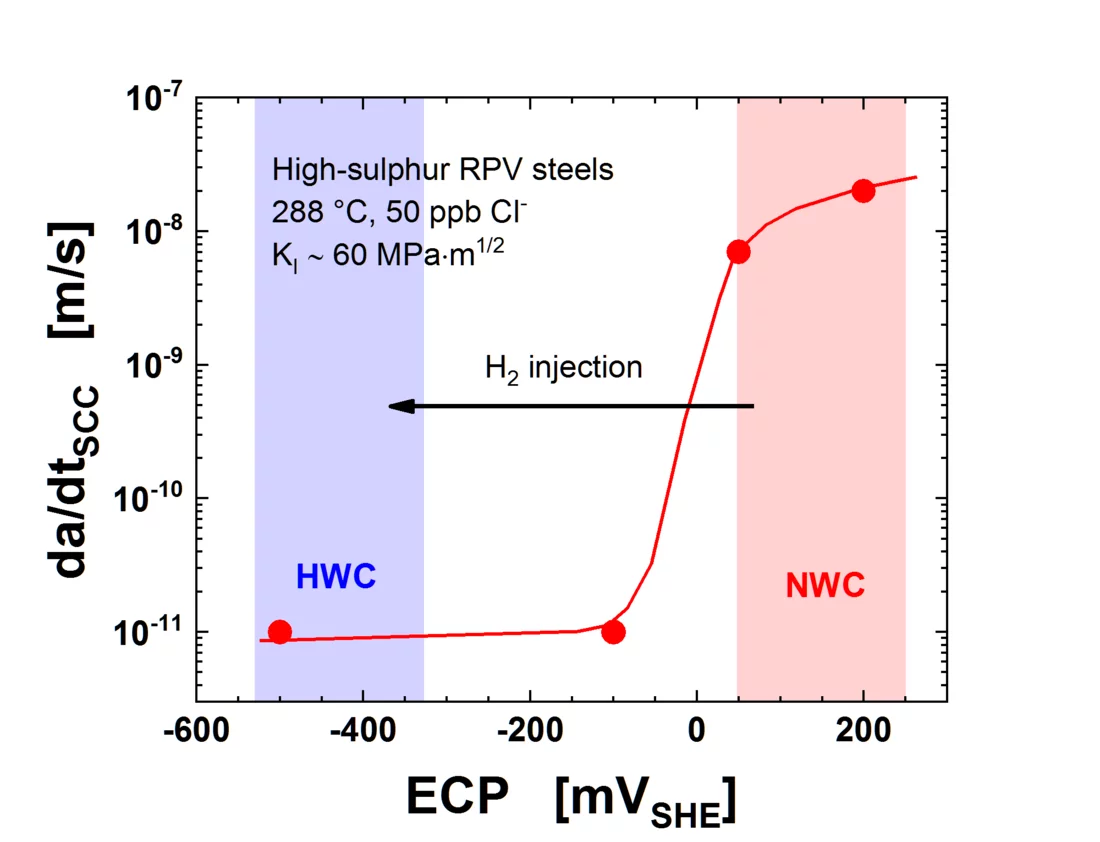

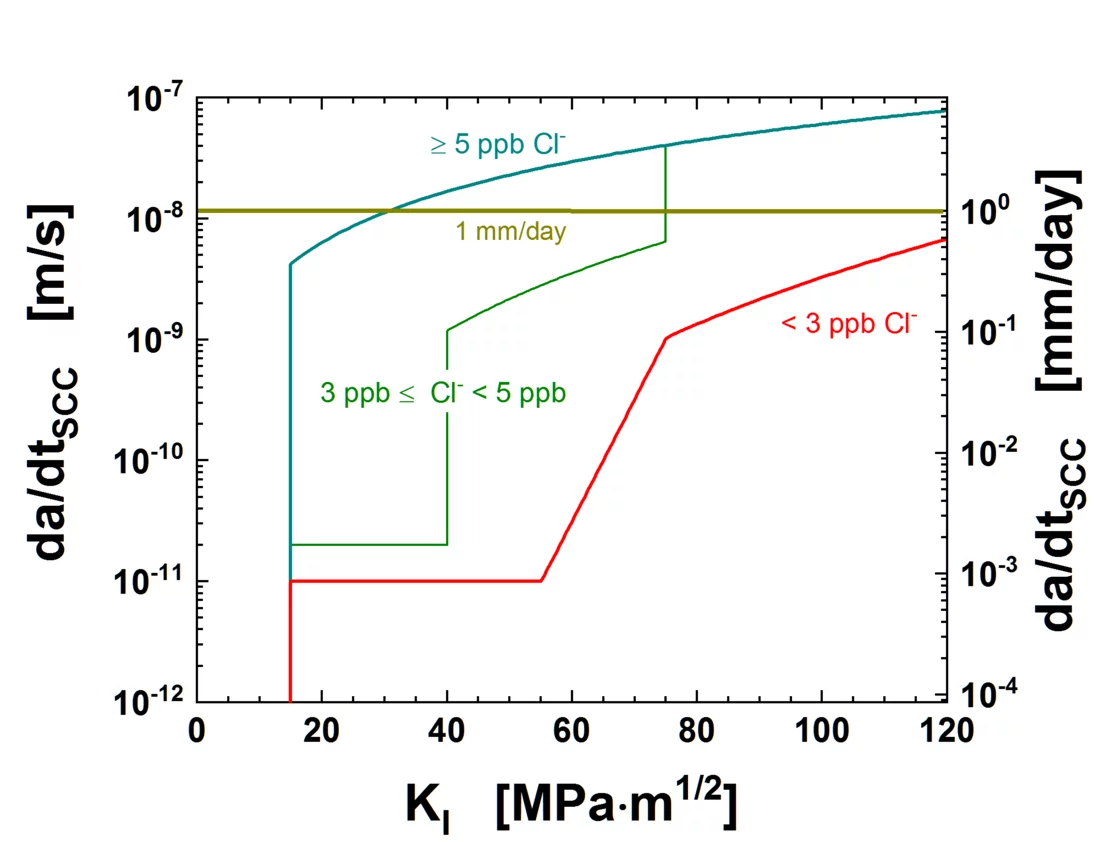

Within several projects that were funded by the Swiss Nuclear Safety Inspectorate (ENSI), LNM has investigated these aspects by very challenging, time-consuming and costly experiments [1-4] and developed new SCC disposition curves in collaboration with the Electric Power Research Institute (EPRI) in the USA [5]. In high-purity water (< 1 ppb of chloride, 1 ppb = 1 µg/kg), SCC crack arrest was observed arrest at the fusion boundary up to high stress intensity factors (Figure 2). On the other hand, small chloride contamination of > 3 ppb caused fast SCC into the RPV down to low stress intensity factors values in BWR/NWC environment! It is thus essential to maintain a high-purity of the reactor water, and the Action Level 1 limit of the EPRI BWR/NWC water chemistry guidelines was reduced to 3 ppb based on these investigations in 2016. In BWRs with reducing hydrogen water chemistry (HWC) (as it is applied in the Swiss BWR KKL and KKM) with hydrogen injection into the feedwater, a much higher chloride tolerance was observed (Figure 3), where no SCC occurred in the RPV steel up to high chloride concentrations of 500 ppb.

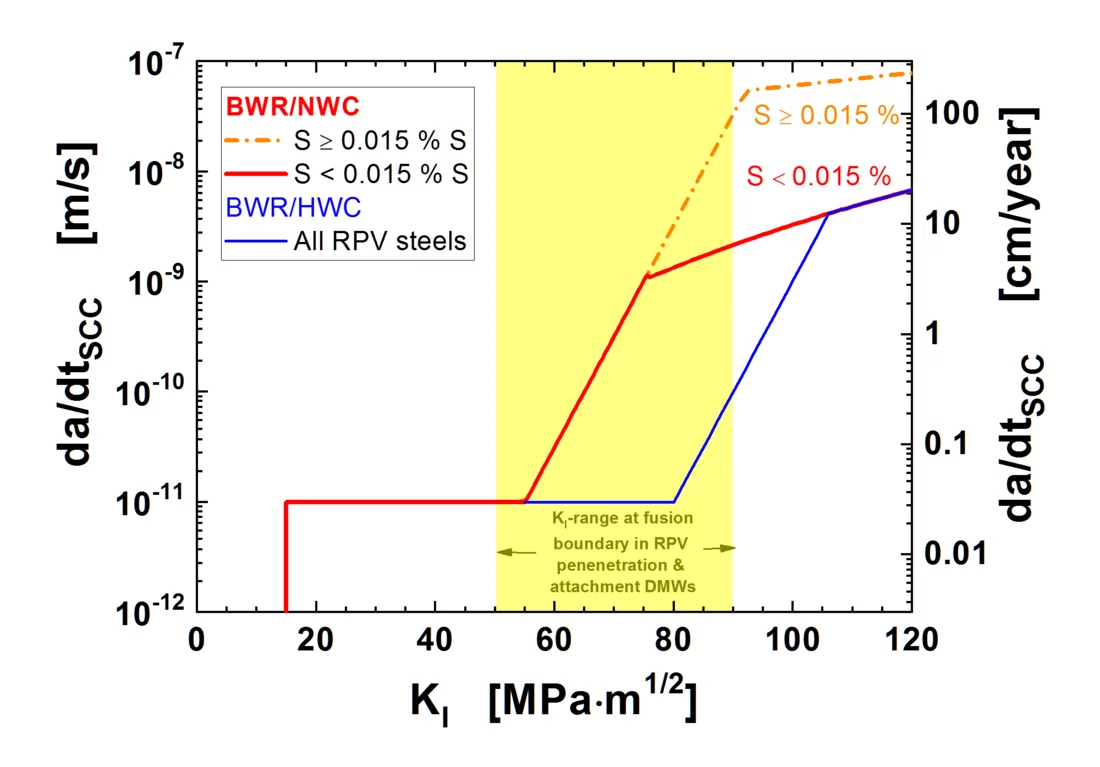

Based on our results and suggestions, new SCC dispositions crack growth curves for RPV steels in BWR/NWC and HWC environment (Figure 4) and during chloride transients (Figure 5) were developed in collaboration with EPRI [5] and implemented in the Code Case N-896 in the ASME Boiler and Pressure Vessel Code in 2019 that were also accepted by the US regulator NRC. These curves are used for flaw tolerance evaluations and integrity assessments of the RPV. With these curves, sufficient safety margins for the RPV could be demonstrated with the current inspection intervals of the periodic in-service inspection for high-purity water. In case of HWC, margins are extremely high, even in case of moderate chloride contamination. It took almost 10 years from the first ideas (PSI publication in 2008) [4] to the acceptance of the Code Case in 2019. The Code Case is an important milestone and contribution to the safe long-term operation of BWRs.

The principal investigator H.P. Seifert has recently received the Coriou Award 2019 of the European Federation of Corrosion (EFC) in recognition of his significant contributions to nuclear corrosion and SCC in the last two decades (Figure 6).

Hans-Peter Seifert

Laboratory for Nuclear Materials (LNM)

Paul Scherrer Institut

E-mail: hans-peter.seifert@psi.ch

Original Publications

[1] H.P. Seifert, S. Ritter, H.J. Leber, S. Roychowdhury, Stress Corrosion Cracking Behavior in the Transition Region of Alloy 182/Low-Alloy Reactor Pressure Vessel Steel Dissimilar Metal Weld Joints in Light Water Reactor Environments, Corrosion 71 (2015) 433-454.

[2] H.P. Seifert, S. Ritter, The influence of ppb levels of chloride impurities on the stress corrosion crack growth behaviour of low-alloy steels under simulated boiling water reactor conditions, Corrosion Science 108 (2016) 134–147.

[3] H.P. Seifert, S. Ritter, The influence of ppb levels of chloride impurities on the stain-induced corrosion cracking and corrosion fatigue crack growth behaviour of low-alloy steels under simulated boiling water reactor conditions, Corrosion Science 108 (2016) 148–159.

[4] H.P. Seifert, S. Ritter, Stress Corrosion Cracking of Low-Alloy Reactor Pressure Vessel Steels under Boiling Water Reactor Conditions, Journal of Nuclear Materials 372 (2008) 114 – 131.

[5] S. Ranganath, R.G. Carter, R. Pathania, S. Ritter, H.-P. Seifert, Evaluation of Stress Corrosion Crack Growth in Low Alloy Steel Vessel Materials in the BWR Environment, in: Proceedings of the ASME 2018 Pressure Vessels and Piping Conference PVP2018 July 15-20, 2018, Prague, Czech Republic, Paper PVP2018-84257.