In recent years several stress corrosion cracking (SCC) incidents occurred in Alloy 182/82 dissimilar metal welds (DMWs) in BWRs and PWRs, which seriously challenged the integrity of the primary coolant circuit in some cases. The detection and, in particular, sizing of such SCC defects in DMWs by current non-destructive testing (NDT) methods are both subjected to relevant uncertainties and errors. Crack depth is often significantly underestimated by NDT.

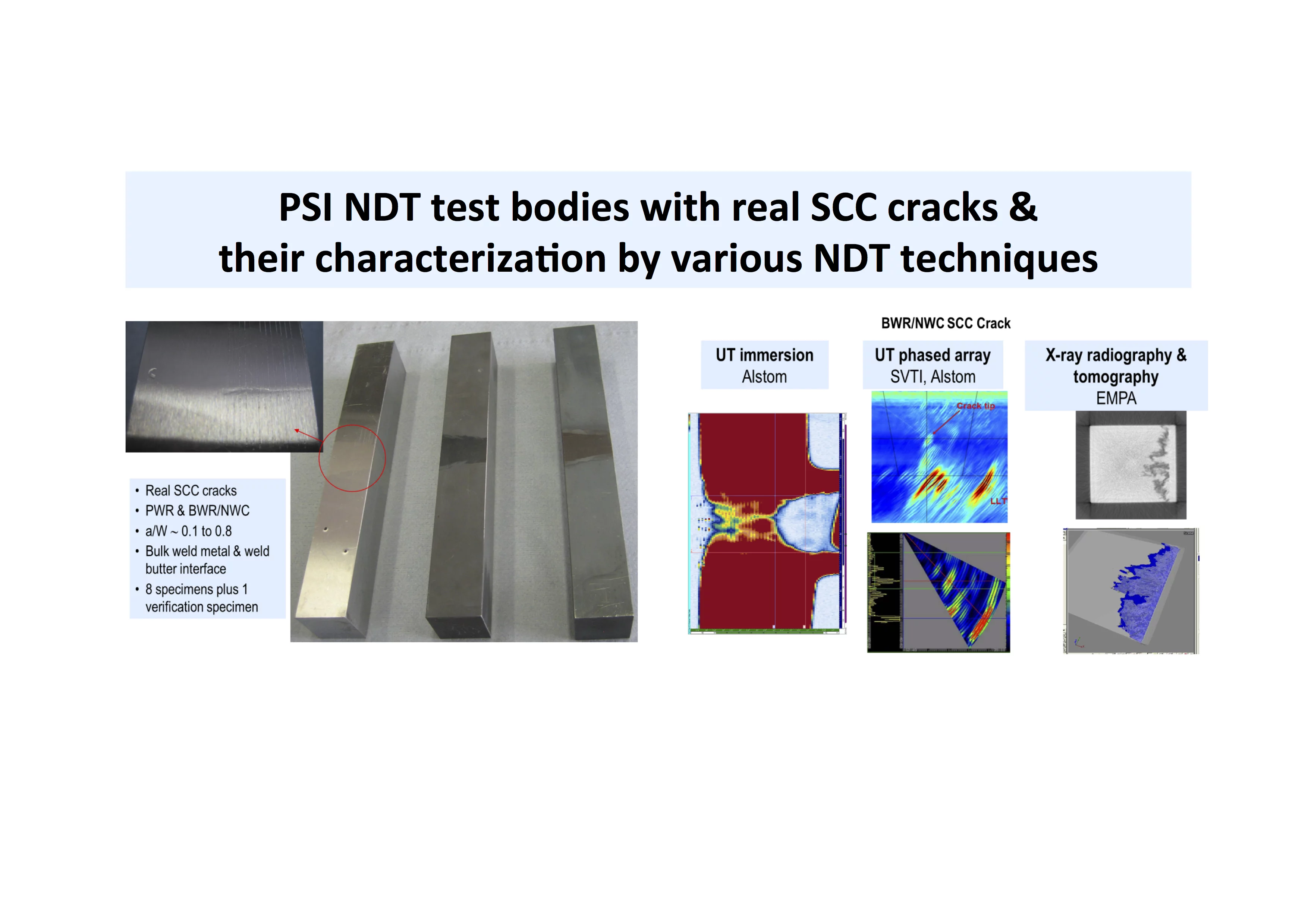

A Swiss consortium of ENSI, PSI, ALSTOM, EMPA and SVTI is participating in the international PARENT program (2011 - 2015), which is dealing with the assessment and quantification of established and new emerging and promising NDT techniques to detect and assess SCC flaws in DMWs. This multinational program is lead by the US NRC and includes regulators, industrial groups and research institutions and started in 2011. In the frame of PARENT, ALSTOM, SVTI and EMPA participate in open and closed round robin programs with different mock-up welds configurations containing artificial defects (EDM notches, fatigue cracks, SCC cracks). The PSI contribution was the challenging task to generate NDT test bodies with different realistic BWR and PWR SCC crack configurations, which can be used to systematically evaluate the limitations of different emerging ultrasonic and eddy current testing methods (UT & ECT) in an open round robin program (location and size of flaws are known by the NDT teams). These are the sole test bodies with real SCC cracks, but they have a simple geometry that significantly facilitates the NDT. In total nine test bodies with SCC and fatigue cracks were fabricated. The generation of NDT test bodies with SCC cracks was extremely time consuming and expensive, in particular in PWR environment, and involved test durations of up to six months! All the SCC cracks in the test bodies were characterized by a special high resolution mechanized UT immersion technique at ALSTOM in Switzerland (Figure 1).

The preliminary results with the PSI specimens clearly reveal that reliable sizing of real SCC defects with state-of-the-art techniques will be rather challenging and related to significant uncertainties. After the termination of the round robin programs, PSI will open selected NDT test bodies and fully characterize the cracks by detailed metallo- and fractography.