Hydrogen will play an important role in a future energy system based on renewable sources, providing energy storage, being a base material for industry and an energy carrier in transport applications. For the efficient electrification of hydrogen, polymer electrolyte fuel cell technology is developed and applied today in trucks, passenger cars and stationary applications. It is envisaged that even more demanding applications such as airplanes may follow. For road transport applications an increase in power density is required to further reduce cost and future applications may need these advances to be technically competitive. In this work we describe a novel concept for gas diffusion layers, highly important for achieving high fuel cell power densities.

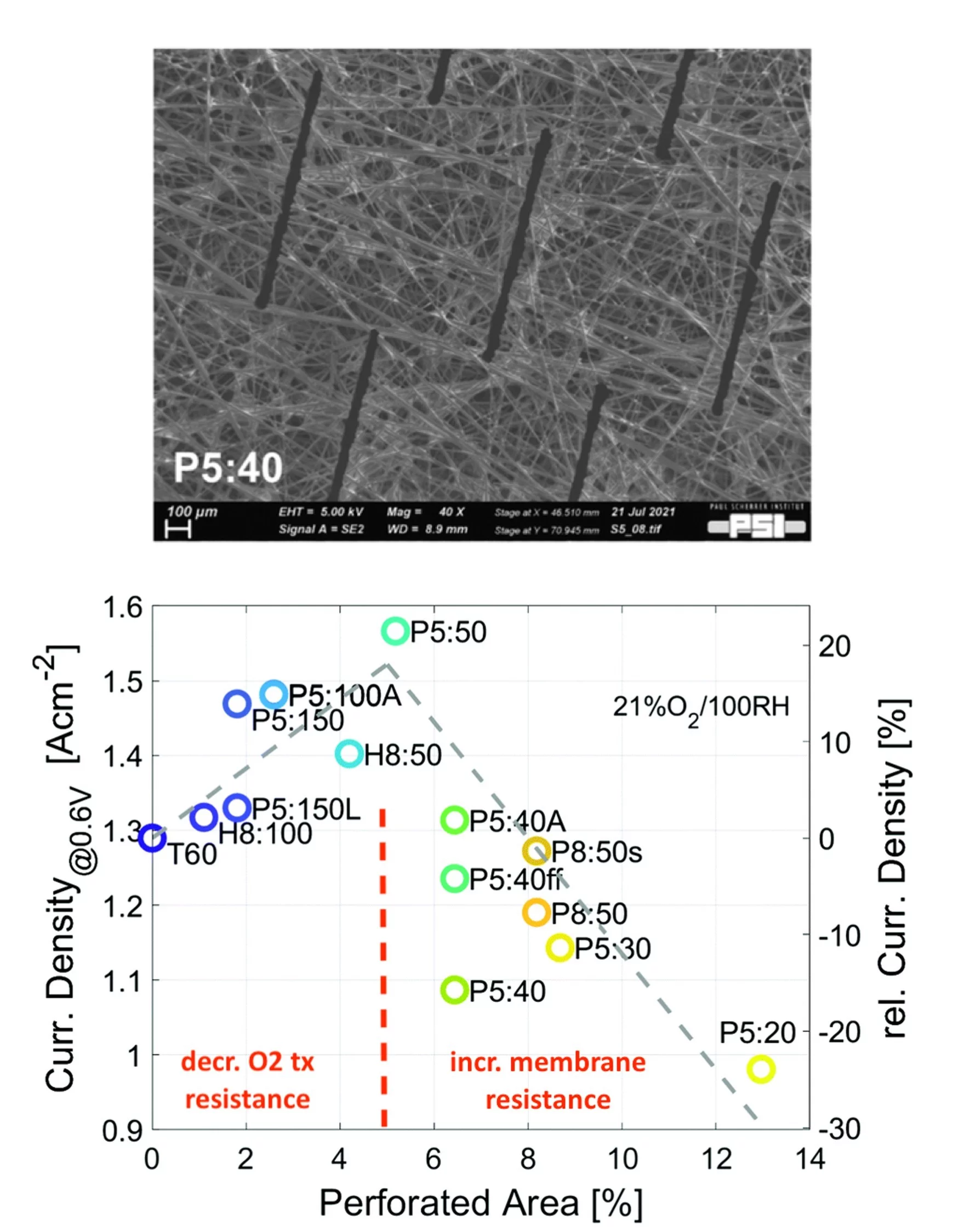

Future high power density fuel cells will operate at higher current densities and thus will have to cope with increased water production rates. In this study we show that the addition of deterministic structures to GDLs with a stochastic pore size distribution improves water and gas transport. A series of 16 laser-perforated patterns, with a systematic variation of perforation width, length and density was designed and characterized to identify the optimum modification pattern. Other than in previous work, where laser-perforated holes were added to already hydrophobized GDLs, here the materials were hydrophobized after laser treatment, to render also perforations and their vicinity hydrophobic. The perforated area was used as a descriptor to compare the wide variety of patterns. The structure and transport properties of the GDL materials are described and their performance is characterized under different operating conditions to probe the impact of the deterministic modifications. Under H2/air operation and wet conditions (80% RHA/100% HC), with the best perforation patterns, cell performance increased at 0.6 V by up to +20%. When simulating future very high current density operation by using 100% O2 as the cathode feed, and the corresponding high water production, the same current density increase at 0.6 V of 20%, was observed. Oxygen transport resistances, obtained from limiting current analysis, showed a 40% to 60% reduction at current densities of 3 A cm−2 under the wet operating conditions, supporting the hypothesis of improved water transport away from the CL to the gas channels. The improvement of water management with increasing perforation density is limited at about 5% perforated GDL area by increasing membrane resistance. Above this threshold, ohmic losses limit the performance gain for more open patterns. The membrane drying effect is more dominant at the anode and can be reduced by an asymmetric GDL combination with a denser GDL at the anode (no or lower perforation) than the cathode (higher perforation). As observed in earlier work, hole patterns show unstable performance, underlining the importance of the slit geometry connecting flow-field channels and lands, being not just a change in pore size distribution. Further improvements still seem possible by optimization of the anode/cathode asymmetric GDL combinations or in combination with specialized MPLs or adapted flow field geometries. The presented simple, but powerful modification technique with perforation of conventional, commercial GDLs presents a way forward for changing and improving the water management by introducing rational, deterministic structures into the stochastic, random GDL pore space. Laser processing or other means of mechanical modifications such as punching, are commonly used in industrial manufacturing. Thus, these mechanical modifications seem suitable for scalable production. In summary, the presented development, with the perforated area as the main descriptor shows the potential of rationally structured GDL, enabling higher current density operation for future fuel cell systems. The generic findings founded on a large number of investigated patterns and thorough scientific analysis, make us confident that this approach can be extended to other types of stochastic, carbon fiber based GDLs to improve water management and fuel cell performance.

Contact

Dr. Felix N. Büchi

Head Fuel Cell Systems and Diagnostics Group

Paul Scherrer Institut

5232 Villigen PSI

Switzerland

Telephone: +41 56 310 24 10

E-mail: felix.buechi@psi.ch

Original Publication

High performance gas diffusion layers with added deterministic structures

C. Csoklich, T.J. Schmidt, and F.N. Büchi

Energy Environ. Sci. 15, 1293-1306 (2022).

DOI: 10.1039/D1EE03246A

Acknowledgement

The authors thank the Swiss Federal Office of Energy for funding this project under the grant SI/501635-01. Furthermore, Roland Gretler is gratefully acknowledged for laser-structuring GDLs, and Thomas Gloor for the technical support.