Introduction

The PEM (Proton Exchange Membrane) water electrolysers produce high purity hydrogen by electrochemical water splitting. The Major advantage of this technology is its dynamics, safety and simplicity of the whole pilot plant. The Anode where water is being split and cathode where hydrogen is evolved are isolated from each other by solid electrolyte what enables PEMWE (Proton Exchange Membrane Water Electrolysers) to electrochemically pressurize the gas up to 300bar.

Project goal

The scope of the project is to examine the gas saturation rate of porous transport layers (PTLs) and catalyst layers (CLs) for various material structures and operating conditions. The oxygen can be treated as by product which effectively blocks the access of water to the catalyst layer and generates mass transport losses. The goal of this study is to gain fundamental understanding on mechanisms occurring within catalyst layer and on the interface between catalyst layer and porous transport layer.

Neutron radiography of electrolyser cells

While considering neutron radiography experiments one needs to estimate the contrast which can be achieved for the selected setup. In case of a PEMWE the usual set of materials is the Titanium for PTLs, the Aluminum for housing and PFSA polymers for the membrane. For such combination water gives enough contrast to extract relatively good quality data after image processing.

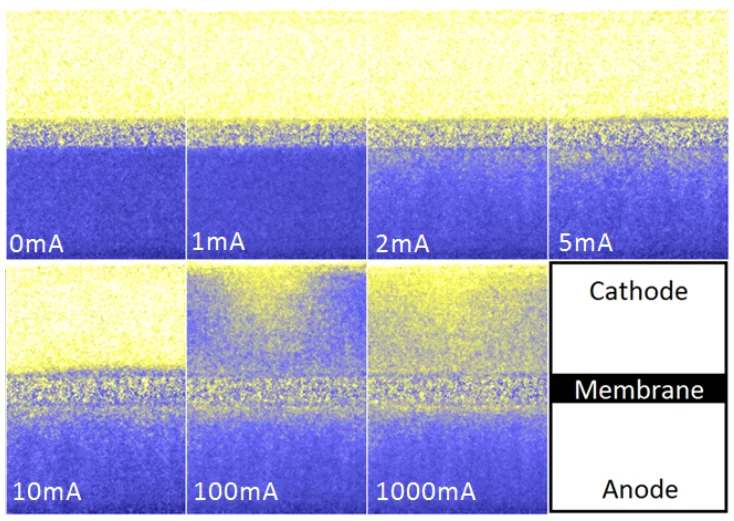

Neutron radiography of water/gas distribution in PEWE

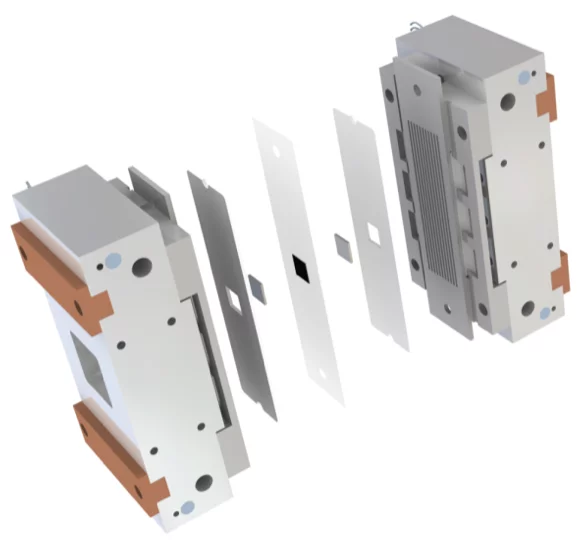

Our Electrolyser cell is designed in a way that provides maximum transparency for both in-plane and through plane imaging configuration while using commercial materials. In order to obtain quantitative images of water and gas distribution within PTLs of a PEWE it is however necessary to use the in-plane imaging setup with a tilted detector adapter for improved resolution. With such an arrangement there is no overlap of the anode and the cathode signals.

Contact

Dr. Pierre Boillat

Electrochemistry Laboratory (LEC) and

Neutron Imaging and Activation Group (NIAG)

5232 Villigen PSI

Switzerland

Telephone: +41 56 310 2743

Fax +41 56 310 4415

Email: pierre.boillat@psi.ch