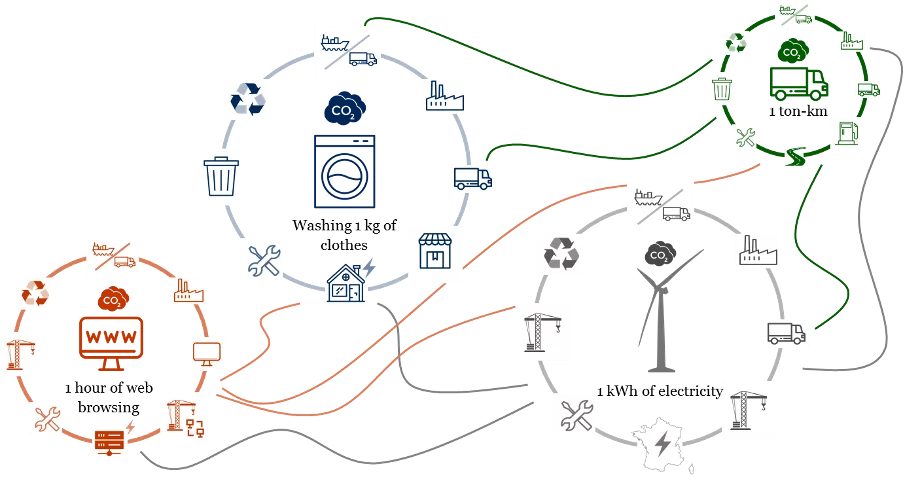

Life cycle analysis (LCA) is the method of choice for quantifying the environmental burdens of products and services, taking into account their production, use and disposal or recycling. An LCA quantifies those burdens along entire supply chains – i.e., from for example extraction of metals, their refining and processing to their use in products – by measuring material and energy flows of all processes involved. The number of processes to be considered is large, since economic activities often constitute a complex network.

A large number of environmental burdens are measured, for example greenhouse gas emissions, fine particles, pollution of water bodies, use of land and other resources, etc. LCA is crucial when comparing products that cause environmental pollution in different phases of their life cycle, for example cars with combustion engines with battery-electric vehicles: While the majority of CO2 emissions of cars with internal combustion engines comes from their exhaust, there are no such emissions from battery-electric vehicles. However, the electricity needed to charge the batteries can cause substantial emissions, depending on the type of power generation.

The LCA focus of the Technology Assessment Group is in the areas of "Energy" and "Mobility". This includes, for example, electricity and heat production, energy storage, the production of synthetic fuels and their use in cars and trucks, ships and airplanes. Technologies that are needed in a society that causes net zero greenhouse gas emissions – such as hydrogen production and storage and technologies for removing CO2 from the atmosphere – are becoming increasingly important in our work.

We not only perform LCA of today's technologies, but also of future ones. To this end, the expected technological progress is taken into account. For this purpose, we also develop tools that combine LCA with (energy) system models and perform prospective LCA. In this way, on the one hand, consistent future scenarios can be designed and used in LCA, and on the other hand, environmental pollution of entire energy systems and their transformation pathways over the coming decades can be assessed under different boundary conditions.

The aim of all of our LCA activities is to support rational decisions, especially in the energy and transport sectors. To this end, we not only publish scientific articles, but also policy briefs and fact sheets for the general public, and we design web tools that allow our work to be used interactively. Furthermore, the outputs of our LCA represent inputs to other areas of our research, e.g., quantification of external costs and internal costs as well as risk assessment, and Multi-Criteria Decision Analysis. The fact that LCA most often acts as “central hub” for all these activities ensures consistency of integrated technology assessment.