Background

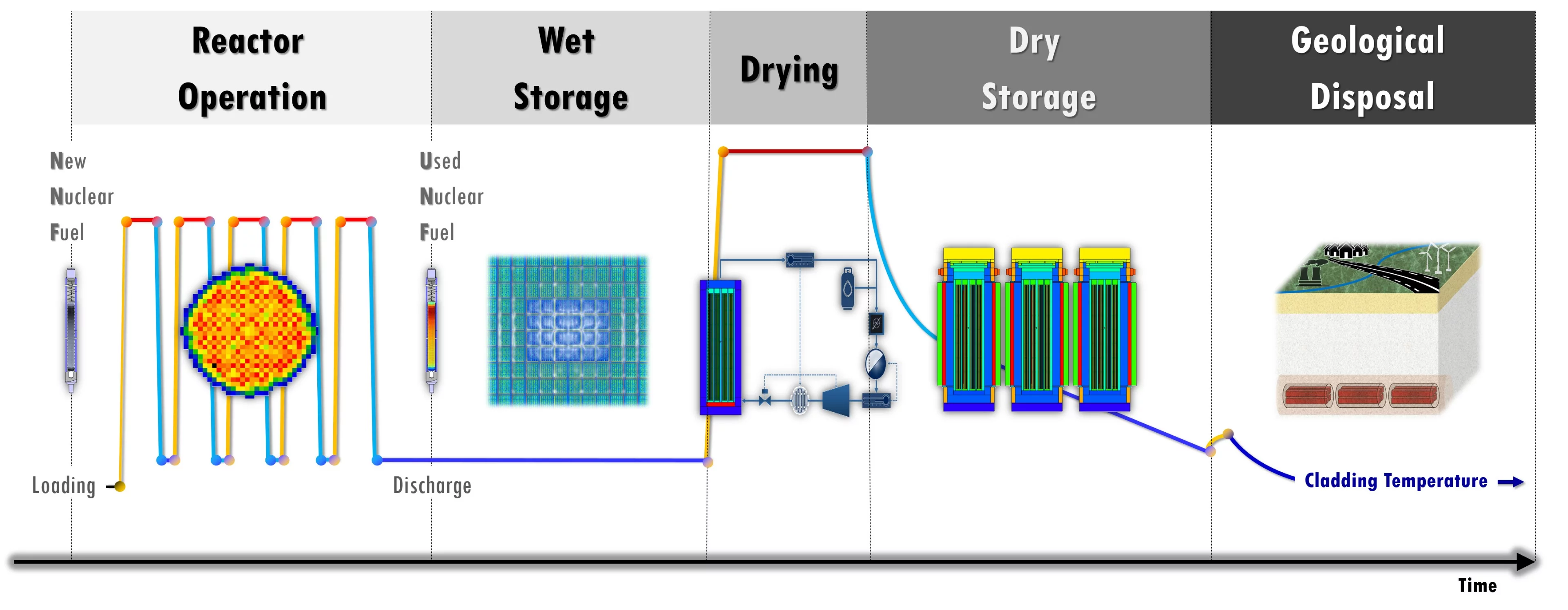

Used nuclear fuel from the Swiss plants is stored in wet pools at reactor sites and in the dry storage facility ZWILAG. In the future, the fuel will be disposed in a geological repository. However, it remains unknown when the final repository will be ready for operation. Therefore, longer interim storage periods might be required. And since the wet storage pools have limited capacities, extended dry storage has also to be considered.

Preserving the fuel integrity and ensuring its safe handling during the entire storage period is therefore of highest priority. In that context, the DRYstars research project was initiated in 2019 in collaboration with the Swiss nuclear regulator ENSI. The central objective of the DRYstars project is to enlarge the capabilities of state-of-the-art simulation tools in order to accurately model and predict phenomena that could affect safety relevant fuel and cladding thermo-mechanical properties during storage.

A first step of DRYstars was to review and identify such phenomena with specific consideration of Swiss plant characteristics in terms of e.g. assembly/fuel design (including previous MOX utilization), in-service reactor core operation to very high burnups and post-discharge spent fuel management systems design and operation (including wet-to-dry-to-wet procedures at certain plants).

The main phenomena identified as relevant, including for the Swiss plants, are shown schematically in Figure 1 and can be classified into three interlinked categories.

The first category relates to helium behaviour. Indeed, considerable amounts of helium are generated via alpha decay of actinides. This leads to fuel swelling, which in turn could induce pellet-cladding mechanical interactions (PCMI), or it can result in a change of the rod internal pressure (RIP). Both these phenomena will affect the stress distribution within the cladding. Regarding release of helium, a literature survey was conducted but suggested that this phenomenon remains negligible under dry storage conditions.

The second category includes cladding creep and fuel-cladding bonding. Both of these can have a significant impact on the cladding mechanical behaviour and associated strength. The third category of important phenomena is associated with hydrogen entering the cladding during reactor operation via waterside corrosion. Hydrogen migrates within the cladding, driven by different gradients, and can precipitate and form hydrides. Hydrides can then become radially oriented if the cladding hoop stresses are sufficiently large. The presence of such brittle radial hydrides reduces the cladding mechanical strength.

Model Developments for Dry Storage Fuel Simulations

Using proper numerical tools is crucial to anticipate the fuel state during extended dry storage. Most codes available at PSI LRT were so far developed and validated with focus on fuel behaviour for-reactor normal operation and transient/accident conditions. To make the same codes fit for simulations of post-discharge operation in general and dry storage in particular, models for all the above mentioned categories of key phenomena are under development. In that context, the following progress has been achieved so far.

Helium Behaviour

Numerous experiments have shown that helium particles generated via alpha decays of actinides interact with atoms in the fuel lattice such as to induce fuel swelling. Available experimental data was therefore used to derive and implement Helium induced swelling models in the state-of-the-art fuel performance code Falcon co-developed at PSI in collaboration with EPRI. On this basis, numerical simulations were conducted and confirmed that helium swelling and its impact on RIP and/or gap closure induced PCMI, both effects resulting in significant changes of the cladding stress distribution, can now be predicted.

Cladding Mechanical Behaviour

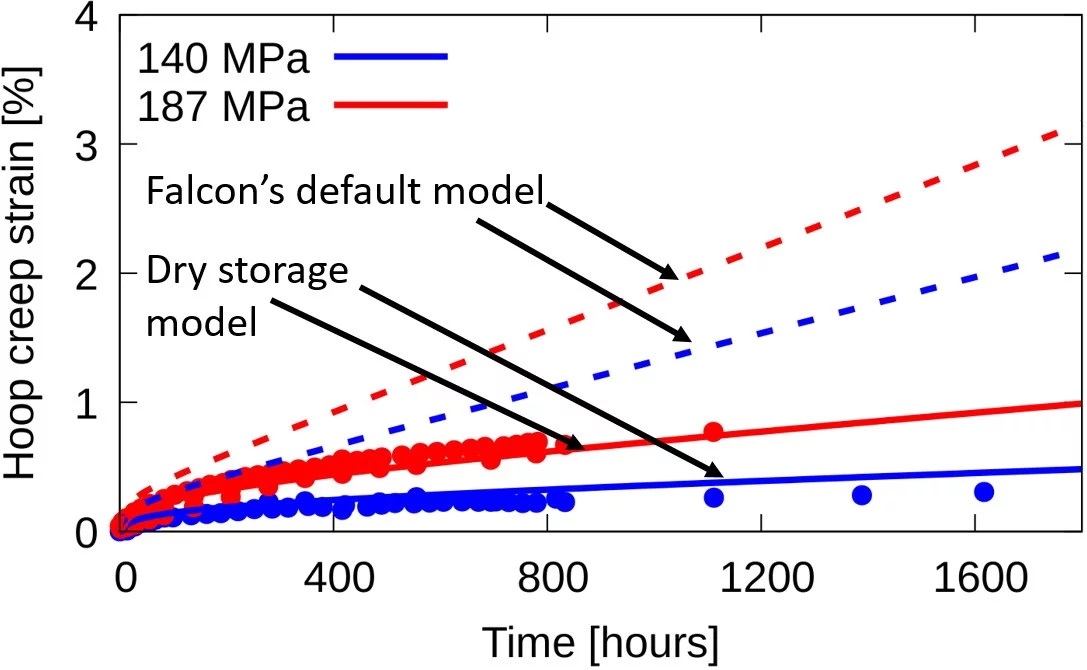

The creep models available in Falcon were designed to model in-service conditions and were initially not foreseen for simulations of the creep behaviour after discharge. Therefore, creep models dedicated to dry storage conditions were developed and implemented in Falcon. For one of these models, a first validation against available out-of-pile experimental data is presented in Figure 2. As can be seen, the qualitative as well as quantitative agreement with measured data of the hoop strain time evolution is now significantly improved when compared to the default Falcon models.

Hydrogen Behaviour

Hydrogen-related effects such as delayed hydride cracking and embrittlement can jeopardize the fuel integrity in dry storage. Therefore, large efforts were invested towards a better modelling of these phenomena. In that context, a finite volume solver was developed to model hydrogen diffusion within the cladding. In addition, models to predict dissolution and precipitation of hydrides and their reorientation were implemented.

Finally, two preliminary models aimed at predicting the onset of delayed hydride cracking and embrittlement were elaborated and tested. All these developments were made such as to allow simulating the hydrogen behaviour for both liner and non-liner claddings as such are widely used in Switzerland. All models were then synthesized into a consolidated computational framework referred to as HYdrogen PostprocEssor (HYPE). The principle of HYPE is to extract all necessary output information from a fuel performance code and use it to calculate hydrogen behaviour, including hydrogen uptake, diffusion, dissolution, precipitation, reorientation and on this basis evaluate failure criteria.

While HYPE can in principle be coupled to any fuel performance code, its first implementation for testing and verification purposes was done in connection with Falcon. An example of the capabilities established through HYPE is provided in Figure 3 where the predicted radial hydrogen distribution across the cladding is shown for an entire full length rod.

Future Work – Towards Multi-Physics and Uncertainty Analysis

Since dry storage cannot be fully supported by experiments due to its long duration, the safety assessment has to rely on higher fidelity numerical simulations. Therefore, a calculation scheme consisting of core simulations, thermal-hydraulics and fuel performance calculations is under development. All these physical domains are crucial for predicting the spatial and temporal evolution of the fuel rod properties. In particular, such multi-physics scheme will allow to study the relationships between in-service fuel operation and post-discharge behaviour in order to better understand their impact on safety requirements during dry storage. An enveloping element of this will be the identification of parameters having the largest impact on the fuel rod integrity through sensitivity and uncertainty analyses.

Contact

Dr. Piotr Konarski

Principal Investigator

Steady-State, Transient and Radiation Safety Analyses Group (STARS)

Laboratory for Reactor Physics and Thermal-Hydraulics (LRT)

Nuclear Energy and Safety Research Division (NES)

Paul Scherrer Institut

Hakim Ferroukhi

Laboratory Head / Project Manager

Original Publications

[1] P. Konarski, C. Cozzo, G. Khvostov, and H. Ferroukhi,

Spent nuclear fuel in dry storage conditions – current trends in fuel performance modeling

Journal of Nuclear Materials, vol. 555, p. 153138, 2021

[2] P. Konarski, C. Cozzo, G. Khvostov, and H. Ferroukhi

Dry storage modeling activities at PSI: implementation and testing of a creep model for dry storage

Kerntechnik, vol. 85, no. 6, pp. 419–425, 2020

[3] P. Konarski, C. Cozzo, G. Khvostov, and H. Ferroukhi

Extension of Falcon’s modelling capabilities to dry storage: development of a new model for hydrogen behavior in duplex claddings

TopFuel 2021 Conference, Santander, Spain, 2021