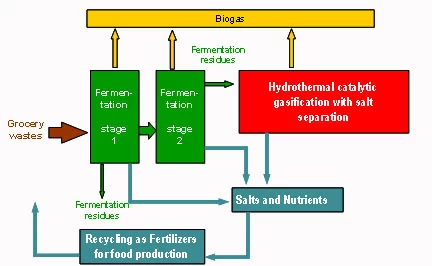

a higher methane yield from organic waste by a combination of anaerobic digestion and hydrothermal gasification

Background/Motivation

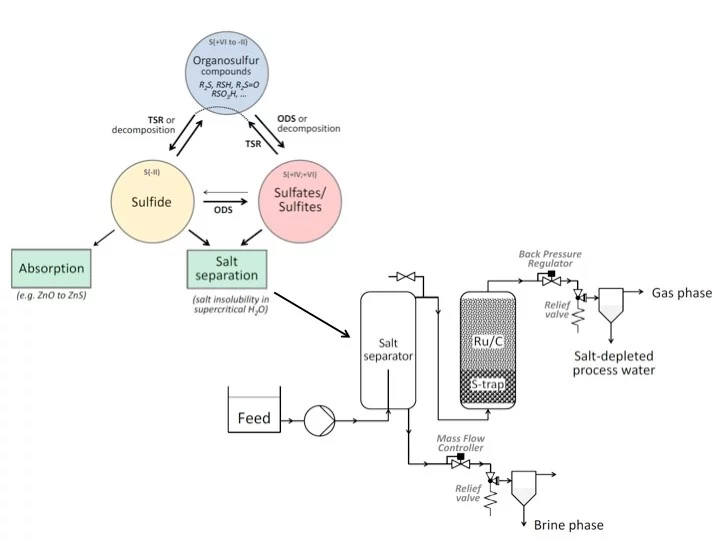

Anaerobic digestion is an established method for methane production out of organic waste. However, not all organic molecules can be transformed to methane via this process. A residue still contining about 60-70% of organic material (dry basis) accumulates, containing mostly lignucellulosic material. Hydrothermal gasification of the fermentation residue may increase the methane yield of organic waste. Additionally, a sanitization of the residue, as it may be required for certain feedstocks, would become unnecessary with this process. Hydrothermal gasification experiments in our lab test rig Konti-2 using slurrys (real feedstocks containing solids) is a new challenge. A special pump has been designed, capable of pumping slurrys against a pressure of up to 350 bar. The broad spectum of composites that make up a real feedstock such as the fermentation residue, as well as seasonal fluctuations make the gasification process a very complex problem.

Approach

A batch reactor system is used to test conditions and screen for challenges in the gasification of fermentation residue. Experiments have been made at different tempartures, residence times, catalyst to biomass ratios and with different catalyst systems. The heat-up phase in the absence of catalysts was investigated as well. With the optimum parameters found in the batch experiments, continuous experiments were performed in the lab test rig Konti-2. The Slurry-Feeder was tested for the first time in this run.

Selected results of batch experiments

A residence time dependent biomass to catalyst ratio of 0.45 g g-1 h-1 (used for comparison with a weight hourly space velocity in a continuous process) was found to result in nearly full conversion with the Ru/C catalyst. A temperature of 400°C was found to maximize the methane yield. A Ru/ZrO2 catalyst, tested under similar conditions, was less active.