The NAPP endstation

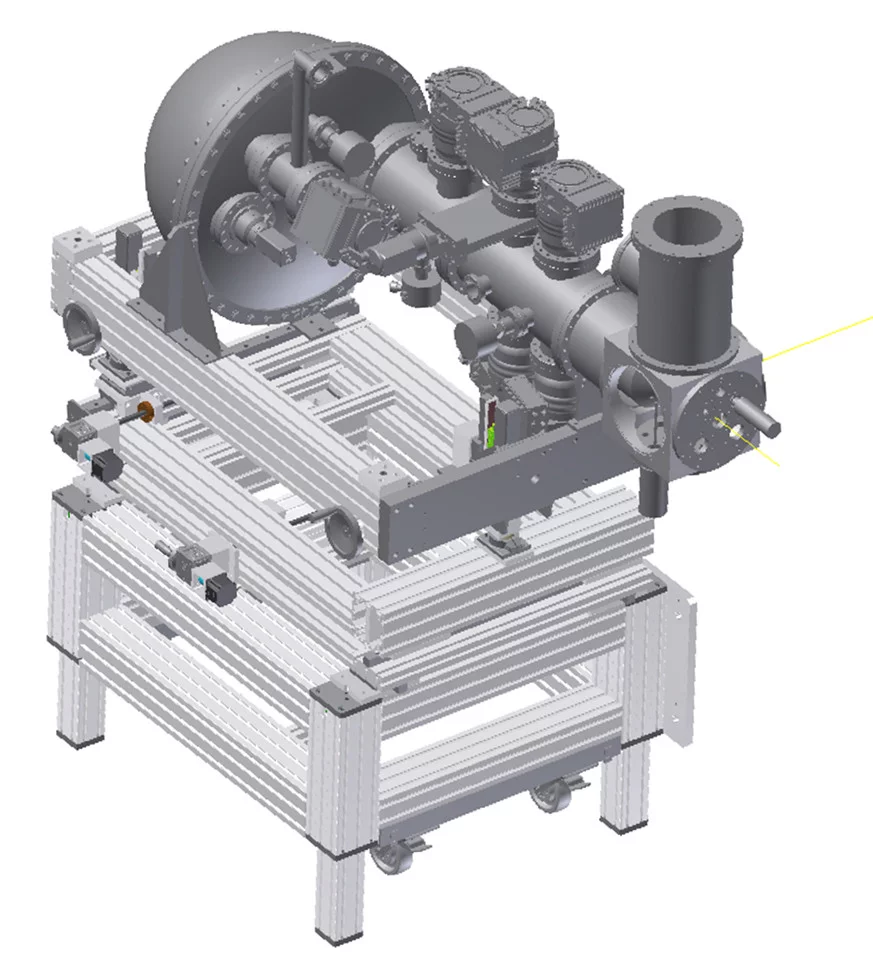

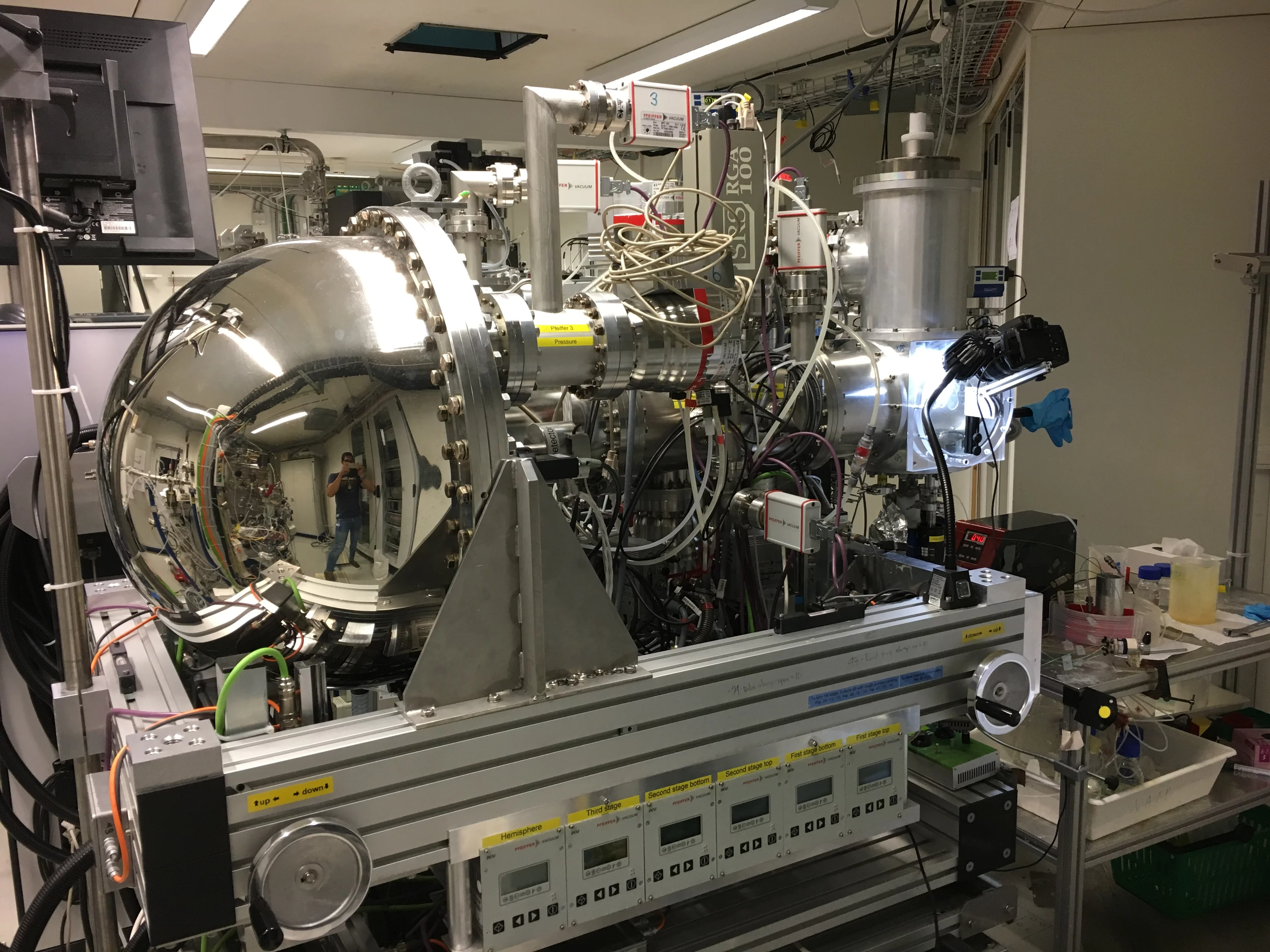

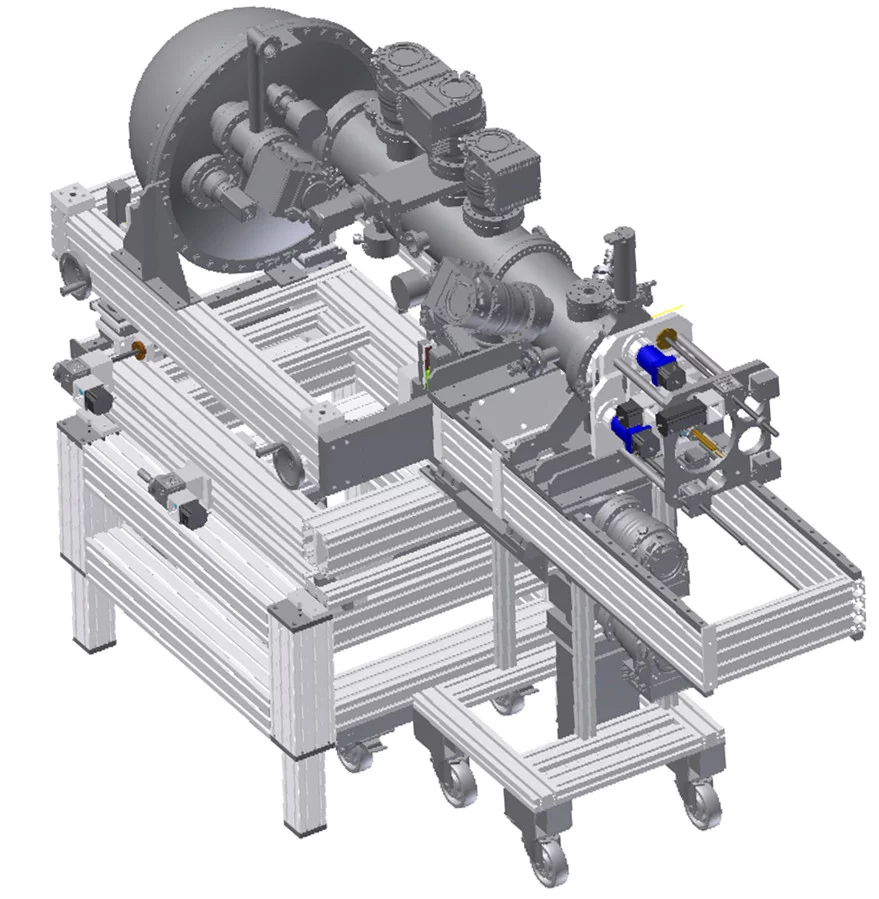

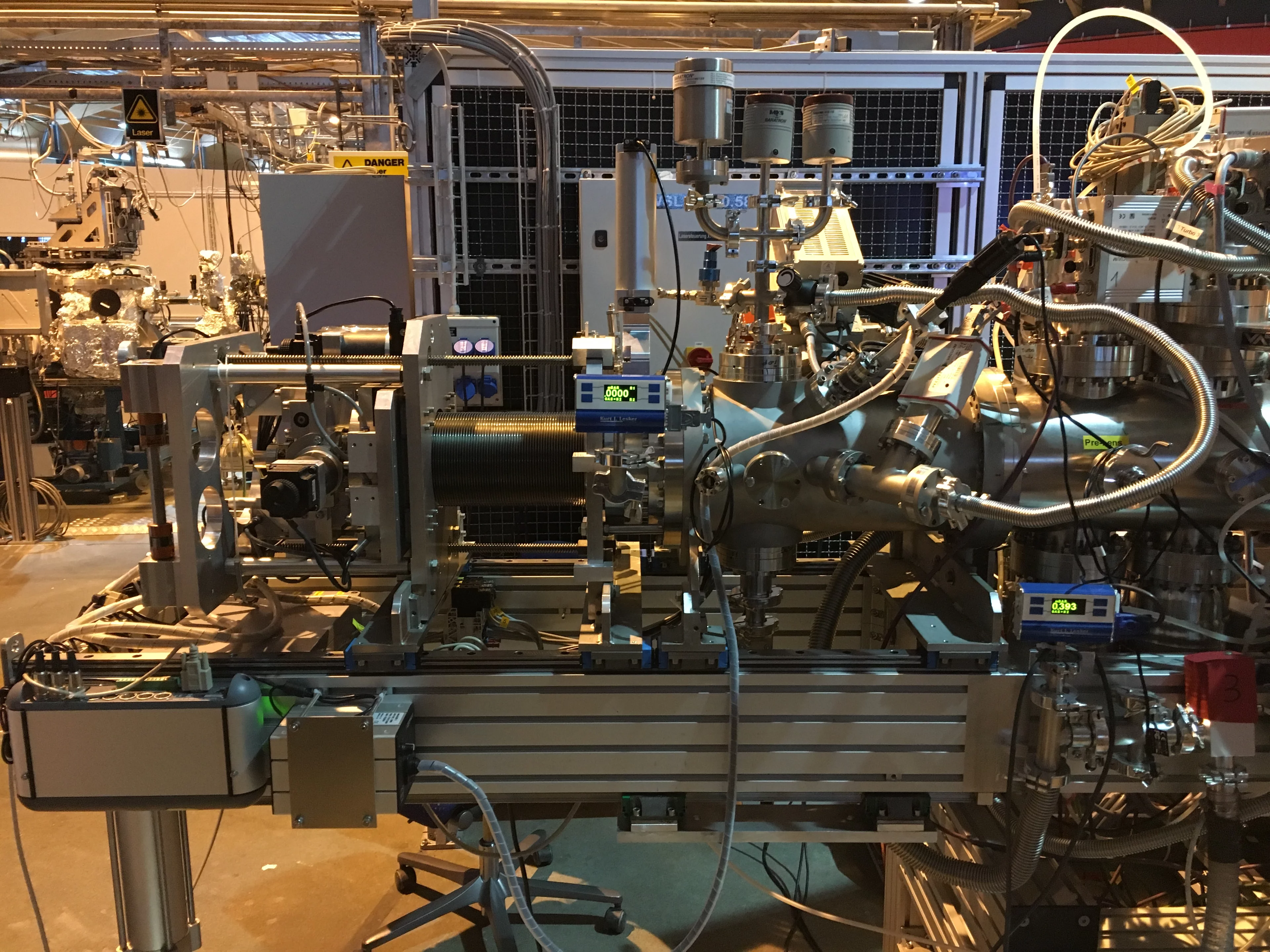

The NAPP endstation operates at the Swiss Light Source (SLS) synchrotron (Paul Scherrer Institut, Villigen, Switzerland) since 2013. The setup, which was cofounded by the SNF R’Equip grant no 139139 (responsibles Prof. Dr. J. A. van Bokhoven and M. Ammann), is constituted by a Scienta R4000 HiPP-2 photoelectron analyzer that can be connected to two experimental chambers.

Liquid-microjet chamber

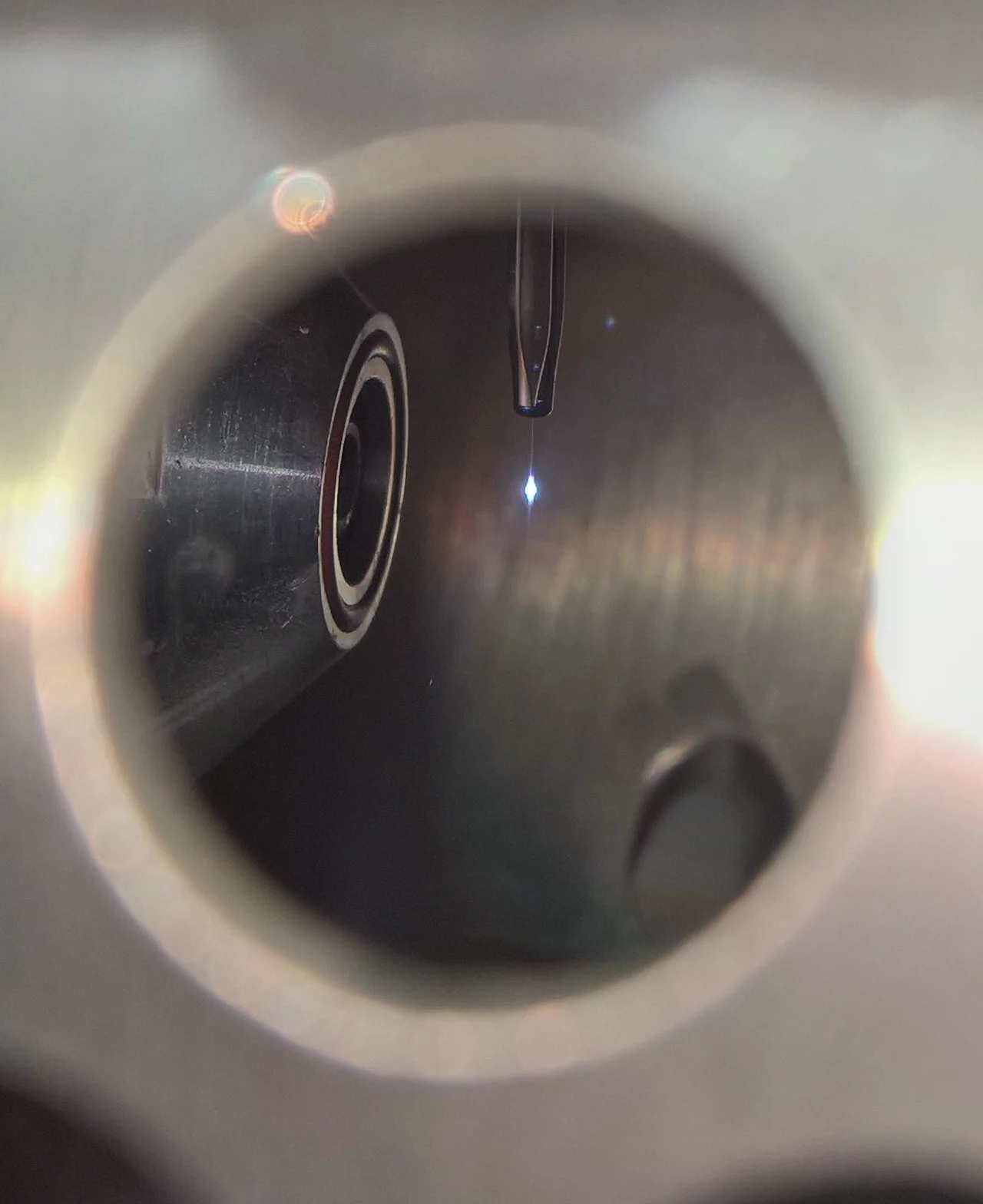

The experimental chamber is a 6-way DN-200 aluminum cube that overlaps the orthogonal incoming photon beam, liquid microjet, and focal point of the electron spectrometer at its center (Rev. Sci. Instrum. 2013, 84, 073904). To minimize the effect of external magnetic fields, a μ-metal shield covers the liquid microjet setup. The liquid microjet setup was purchased from Microliquids GmbH http://www.microliquids.com/). Quartz nozzles having diameters in the 10-50 μm range are commonly used. The microjet assembly is fixed to a XYZ manipulator (nonmagnetic material, Piezo-driven, SmarAct GmbH). The liquid is injected by means of a HPLC pump (air side).

Liquid-microjet chamber

The experimental chamber is a 6-way DN-200 aluminum cube that overlaps the orthogonal incoming photon beam, liquid microjet, and focal point of the electron spectrometer at its center (Rev. Sci. Instrum. 2013, 84, 073904). To minimize the effect of external magnetic fields, a μ-metal shield covers the liquid microjet setup. The liquid microjet setup was purchased from Microliquids GmbH http://www.microliquids.com/). Quartz nozzles having diameters in the 10-50 μm range are commonly used. The microjet assembly is fixed to a XYZ manipulator (nonmagnetic material, Piezo-driven, SmarAct GmbH). The liquid is injected by means of a HPLC pump (air side).

Solid-gas interface chamber

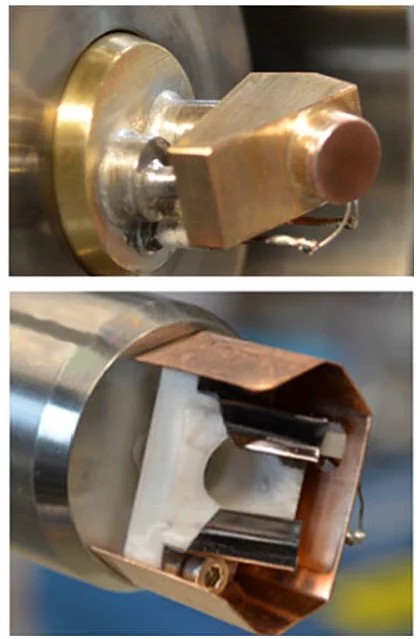

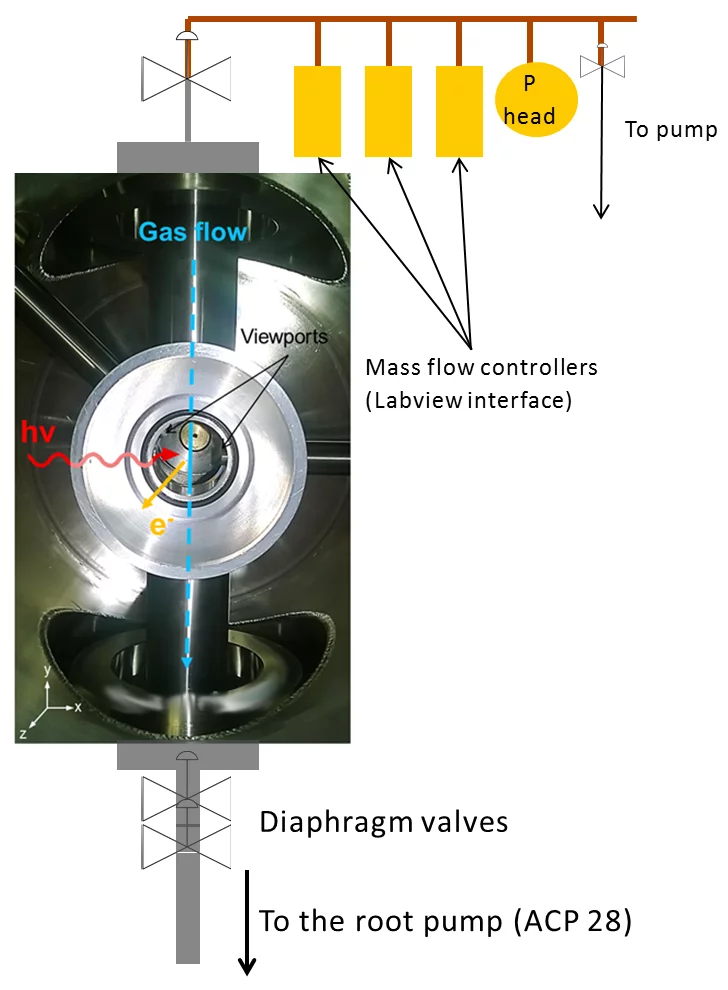

The experimental chamber has been entirely developed at the Paul Scherrer Institut. The outer cylindrical vacuum chamber allows connecting to the HiPP-2 analyzer, the beamline, and hosts the experimental chamber. The outer chamber and the experimental chamber are separated by a silicon nitride membrane (beam side), so that high vacuum can be preserved at the beamline side during experiments. The experimental chamber, made of aluminum, adopts a flow tube configuration and is covered by a μ-metal shield to minimize the effect of external magnetic fields. The diameter of the tubes is 30 mm, and their length 150 mm (for more details see Top. Catal. 2016, 59, 591-604). Depending on the experiment, two manipulators can be used: i) a cryo-holder (liquid nitrogen) allows precise control of the temperature in the -110 - 100°C temperature range; ii) a heated sample holder allows to perform experiments in the room temperature-1000°C range by means of a IR laser diode (975 nm, 25 W) hitting the sample holder on the back side.

Catalysis focusing on time resolution

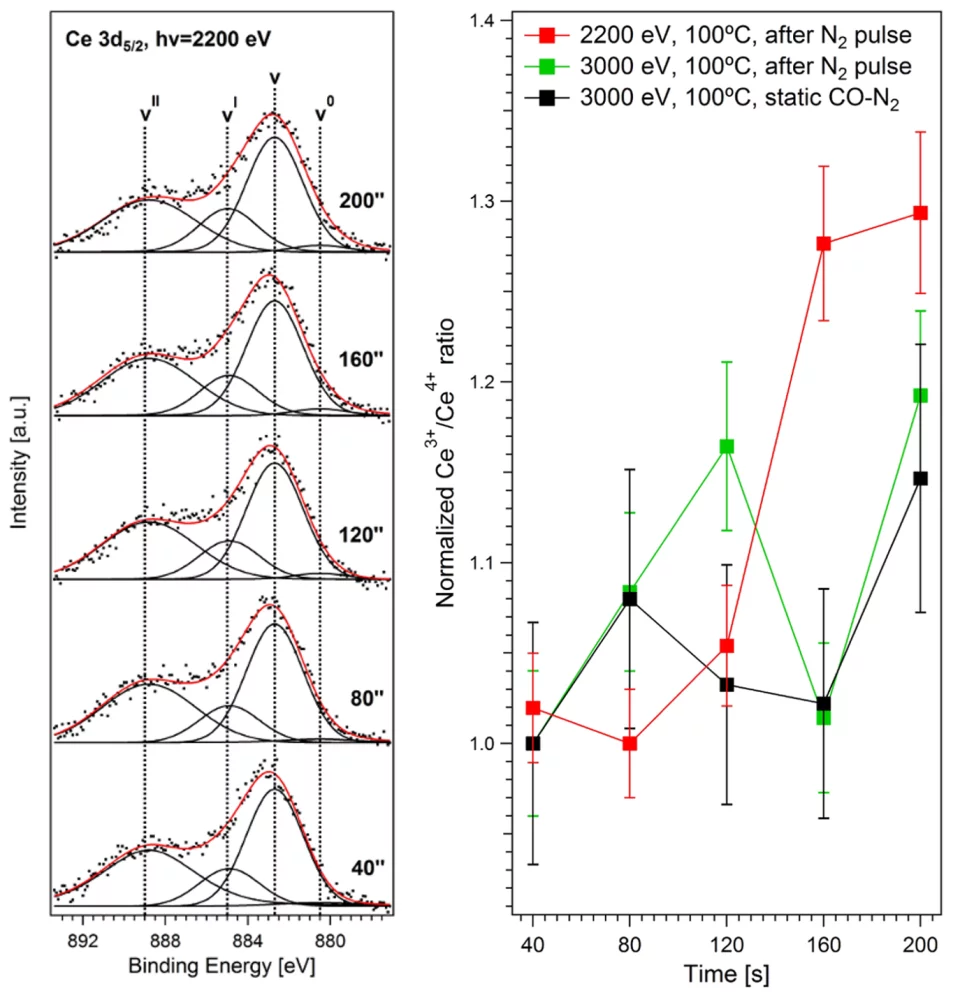

The nature and role of the active species involved in catalytic reactions is still a matter of debate. This is due mainly to the low concentration of active sites, their short lifetime, and the requirement to distinguish them from inactive spectators. The detection of short-lived active species is not possible under steady state conditions. Time-resolved measurements are better achieved under transient conditions, that is, changing the gas or liquid feed concentration in an attempt to detect a modification of the population of active sites.

Since the beginning of 2016, the flow-tube configuration of the static chamber has been exploited to achieve time resolved experiments applied to catalysis. Gas/Gas mixtures are prepared in a gas line connected to mass flow controllers, and dosed into the experimental cell. A root pump coupled with a diaphragm valve is used to remove the gas/gas mixture and to control precisely the pressure in the experimental chamber.

This experimental setup allowed switching from a gas/gas mixture to another within 10-15 seconds. Acquiring the photoemission spectra of a selected element either in fast-scan mode or in fixed mode allows getting photoemission spectra in a time scale ranging from a second to a few tens of seconds. By combining fast switch of the reagents and fast acquisition mode it is possible to detect modifications (i.e. changes in the oxidation state of an element) of the photoemission spectra as a function of time under transient conditions. The heated sample holder allows a precise control of the temperature during the experiment, as well as the possibility to vary it within seconds. Our recent publication (J. Phys. Chem. Lett. 2017, 8, 102-108) shows that active Ce3+ sites can be detected during the oxidation of carbon monoxide on Pt/CeO2 powder catalyst under transient conditions.

The experimental setup can be further improved to reach a time resolution in the second to subsecond range, depending on the system investigated and pressure in the experimental cell. Time-resolved analyses as a function of the heating temperature are also possible.

Catalysis & Environmental chemistry: liquid-gas interfaces

The liquid microjet setup available at NAPP allows the in-situ analysis of liquid interfaces. Liquid microjets produce a narrow wire of liquid continuously flowing close to the analyzer aperture with a velocity ranging from 30 to 120 m/s. This limits the evaporative cooling of high vapor pressure liquids.

We focused our attention on liquid-gas interfaces, because of their importance in catalysis and environmental chemistry. Gas/Gas mixtures can be dosed around the liquid filament:

We focused our attention on liquid-gas interfaces, because of their importance in catalysis and environmental chemistry. Gas/Gas mixtures can be dosed around the liquid filament:

- i) using a standard approach, i.e. by beams of a leak valve connected to a gas line. The advantage is that the pressure of the gas is known and can be controlled. The main disadvantage is that the maximum pressure is limited to a few mbar, and the chamber walls can perturb the reaction.

- ii) using a local gas dosing system. An upgrade of the liquid microjet (Microliquids GmbH) allows dosing higher pressures of gas/gas mixtures exclusively around the liquid filament. The gas flows through a titanium nozzle connected to a gas delivery system (air side).

If the kinetics of the reaction at the liquid-gas interface allows it, reaction intermediates can be detected in the 100 μs between the injection and the detection point.

Nature Commun. 8, 700 (2017).