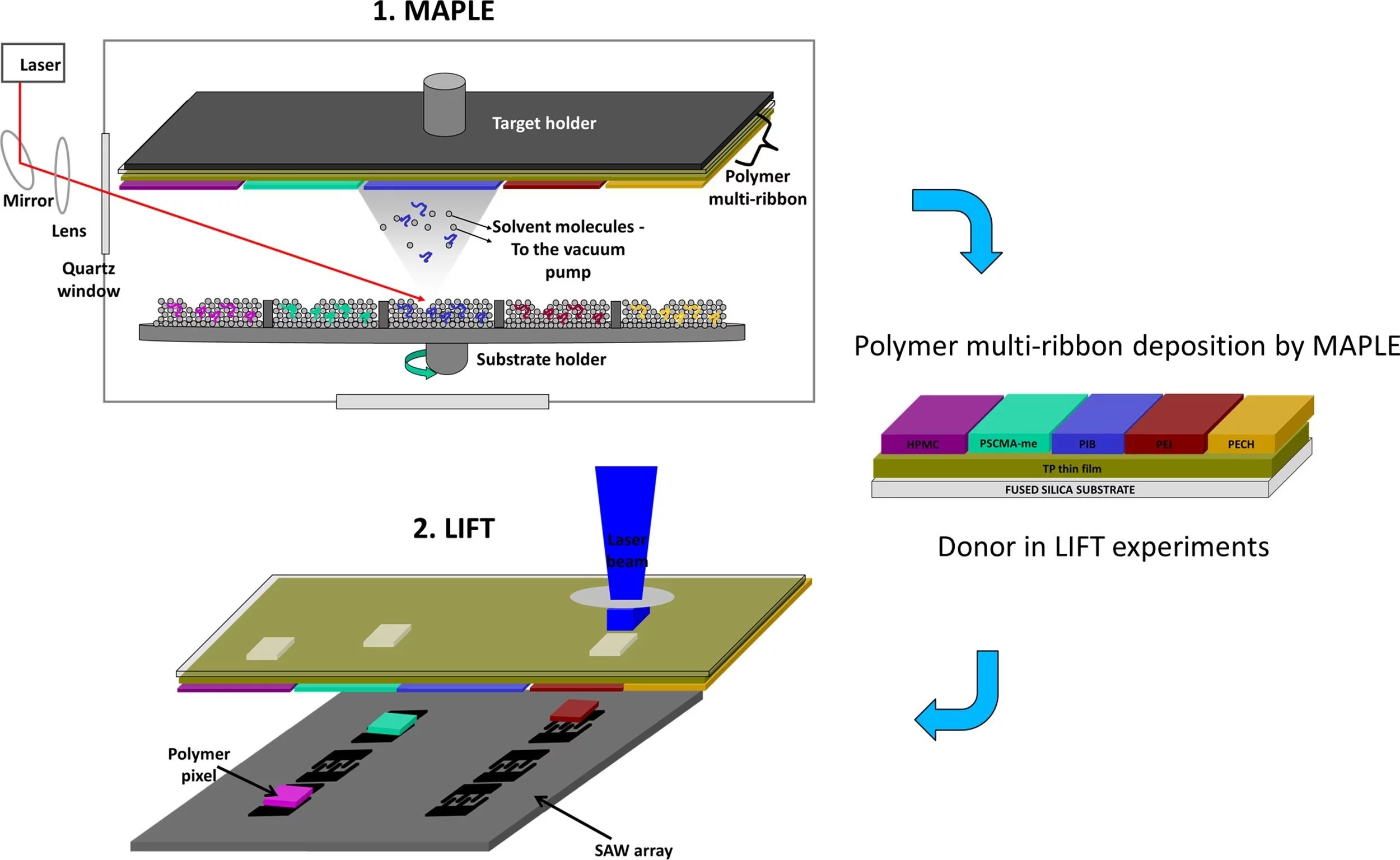

In this paper, we present an e-nose for the detection of volatile compounds based on an array of six surface acoustic wave (SAW) resonators coated with five different polymers (i.e. polyepichlorohydrin, polyisobutylene, polyethylenimine, (hydroxypropyl)methyl cellulose, and poly(styrene-co-maleic acid) partial isobutyl/methyl mixed ester, plus an uncoated SAW device used as reference. In particular, matrix assisted pulsed laser evaporation was used to deposit thin polymer layers which were subsequently used as donor films in the laser induced forward transfer process to selectively cover each SAW resonators of the array. The SAW e-nose was tested upon exposure to vapors of ethyl acetate, dimethyl methylphosphonate, dichloromethane, dichloropentane, and water. The frequency responses showed, for each of the sensors, a different sensitivity to the selected chemical agents and a good agreement with the theoretical sensitivities derived from the linear-solvation-energy-relationship between vapors and polymers. Specifically, the implemented SAW e-nose allowed the discrimination between all the considered vapors in the tested concentrations ranges as highlighted by the results of principal component analysis. Finally, the obtained results indicated that laser deposition of polymers onto SAW resonators is possible without significant modifications of their functionality and with a good reliability and reproducibility.

Keywords: LIFT; MAPLE; SAW; Polymer coating; Sensors; e-nose;

Facility: Thin Films and Interfaces, LMX, National Institute for Lasers, Plasma, and Radiation Physics, Romania, Institute for Photonics and Nanotechnologies & Institute for Microelectronics and Microsystems, Italian National Research Council, Italy

Reference: M. Benetti et al., Sensors & Actuators: B. Chemical 283, 154-162 (2019)

Read full article: [here]