Fluid catalytic cracking, a century old chemical conversion process utilizing porous composites of zeolite and clay, up to this day provides the majority of the world’s gasoline. Owing to harsh reaction environments and feedstock impurities the employed catalysts deactivate, necessitating their continuous fractional replacement with major refineries requiring up to 40 tons of fresh catalyst in total on a daily basis. Using a combination of ptychographic, x-ray diffraction and -fluorescence tomography researchers from PSI and ETH elucidated the structural changes behind catalyst deactivation.

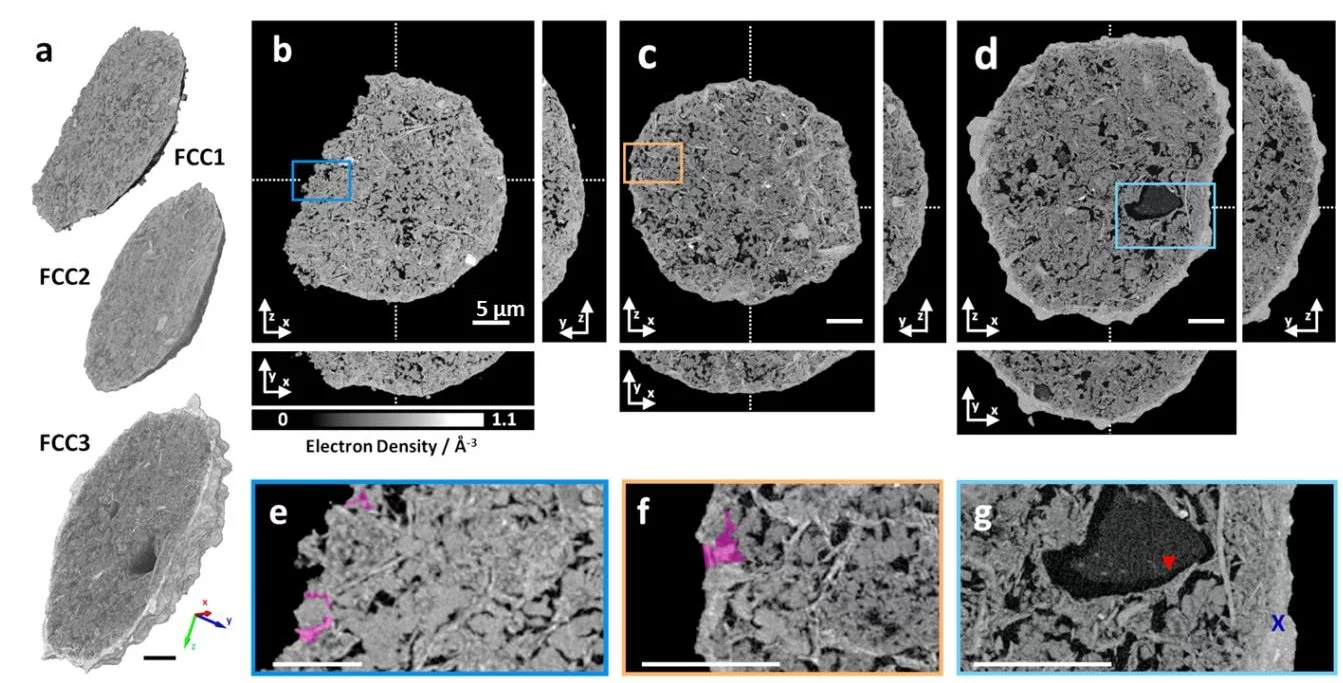

Ptychographic tomography imaging systems operated by the Coherent X-ray Scattering (CXS) group of the Swiss Light Source allowed the investigation of pristine and increasingly deactivated fluid catalytic cracking catalyst particles to true spatial resolution of 30 nm. Examination of the deactivation accompanying structural changes lead to the proposition of two deactivation causes. Catalyst deactivate due to the formation of an increasingly impermeable amorphous silica alumina envelope, isolating the particle and reducing the flux of feed to and product away from the active sites within the composite and a radially progressing zeolite amorphization and mesoporosity, reducing the total catalytic capacity. Observations generally validated by X-ray fluorescence-, X-ray diffraction tomography (microXAS) and electron microscopy (SCOPEM). Researcher’s at ETH Zürich alongside industry partners are currently exploring options of catalyst regeneration and redesign based on these observations.

Contact

Dr. Johannes IhliPostdoctoral fellow, Swiss Light Source

Paul Scherrer Institut

Telephone: +41 56 310 4050

E-mail: johannes.ihli@psi.ch

Dr. Andreas Menzel

CXS group leader, Swiss Light Source

Paul Scherrer Institut

Telephone: +41 56 310 3711

E-mail: andreas.menzel@psi.ch

Prof. Dr. Jeroen A. van Bokhoven

Professor for Heterogeneous Catalysis, Institute for Chemical and Bioengineering, ETH Zurich and Head of Laboratory for Catalysis and Sustainable Chemistry, Paul Scherrer Institute

Telephone: +41 56 310 5046

E-mail: jeroen.vanbokhoven@psi.ch

Original Publication

Three Dimensional View of Structural Changes caused by deactivation of Fluid Catalytic Cracking Catalysts.Ihli J., Jacob R.R., Holler M., Guizar-Sicairos M., Diaz A., Silva J.C.d., Sanchez D.F., Krumeich F., Grolimund D., Taddei M., Borca C., Cheng W.-C., Shu Y., Menzel A., Bokhoven J.A.v. A

Nature Communications 8, 809 (2017)

DOI: 10.1038/s41467-017-00789-w