In any market, cost is the primary, decentralized way of making trade-offs between competing options and allocating limited resources. Internal costs are paid directly by market participants, whether producers or customers, affecting their decisions, while external costs (e.g. health, risk or environmental costs) are paid indirectly by society as a whole.

The Technology Assessment (TA) group’s economic analysis starts with internal costs for specific technologies, and adds external costs for societal damages to obtain total technology costs. Technology costs are also used as inputs for energy system modeling, since operating decisions for the whole system affect costs for both individual technologies and the whole system. As with other research areas within technology assessment, the main areas of focus for cost analysis are electricity production and vehicle transport.

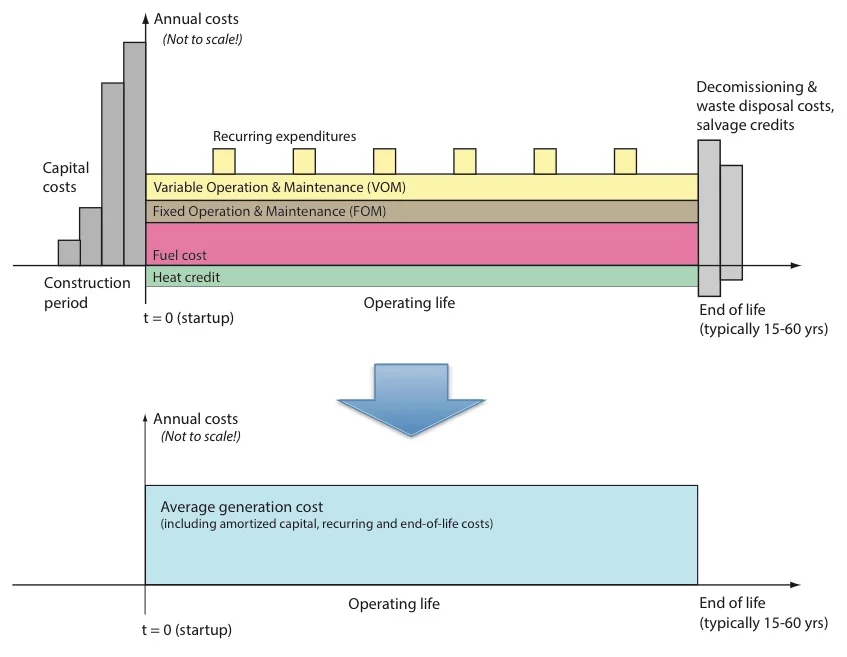

For internal cost analysis, the main method used is levelized or average cost (Figure 1, below). The fixed costs of construction and operation are estimated, as well as the variable costs (fuel and maintenance), over the whole life of a technology. Plant (or vehicle) life, interest rates and expected generation (travel) are used to calculate average cost per kWh (or per passenger kilometer). In some cases, non-energy revenues must also be included, as for cogeneration of heat or ancillary grid services. System boundaries are also important, especially if a technology requires related infrastructure investment, like energy storage, transmission, or roads. In addition to internal cost, additional economic indicators are calculated that are of particular interest to stakeholders, including total investment cost, marginal or variable cost, and resource dependency and risk.

Future costs depend on a range of uncertain data, as well as system expansion and operating choices, so economic analysis includes both scenario analysis and a broad sensitivity analysis. When possible, a model of investment and operating costs is linked to a physical model, reflecting relative component sizes and efficiencies, which allows exploration of technology design and operating scenarios. Ideally, these linked physical and cost models are also linked to a Life Cycle Assessment (LCA) model to also provide scenario LCA burdens.

The results of TA group’s economic analysis are used as inputs for internal energy economics system modeling using least-cost optimization modeling of future scenarios, for tradeoff analysis between both individual technologies and policy scenarios, and as important criterion indicators for Multi-Criteria Decision Analysis.